Manufacturing method of panel-type heat pipe

The invention relates to a technology of a flat-plate heat pipe and a manufacturing method, which are applied in the field of heat pipe manufacturing, and can solve the problems of large thermal resistance and poor heat dissipation performance of the flat-plate heat pipe, and achieve the effects of small thermal resistance and good heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

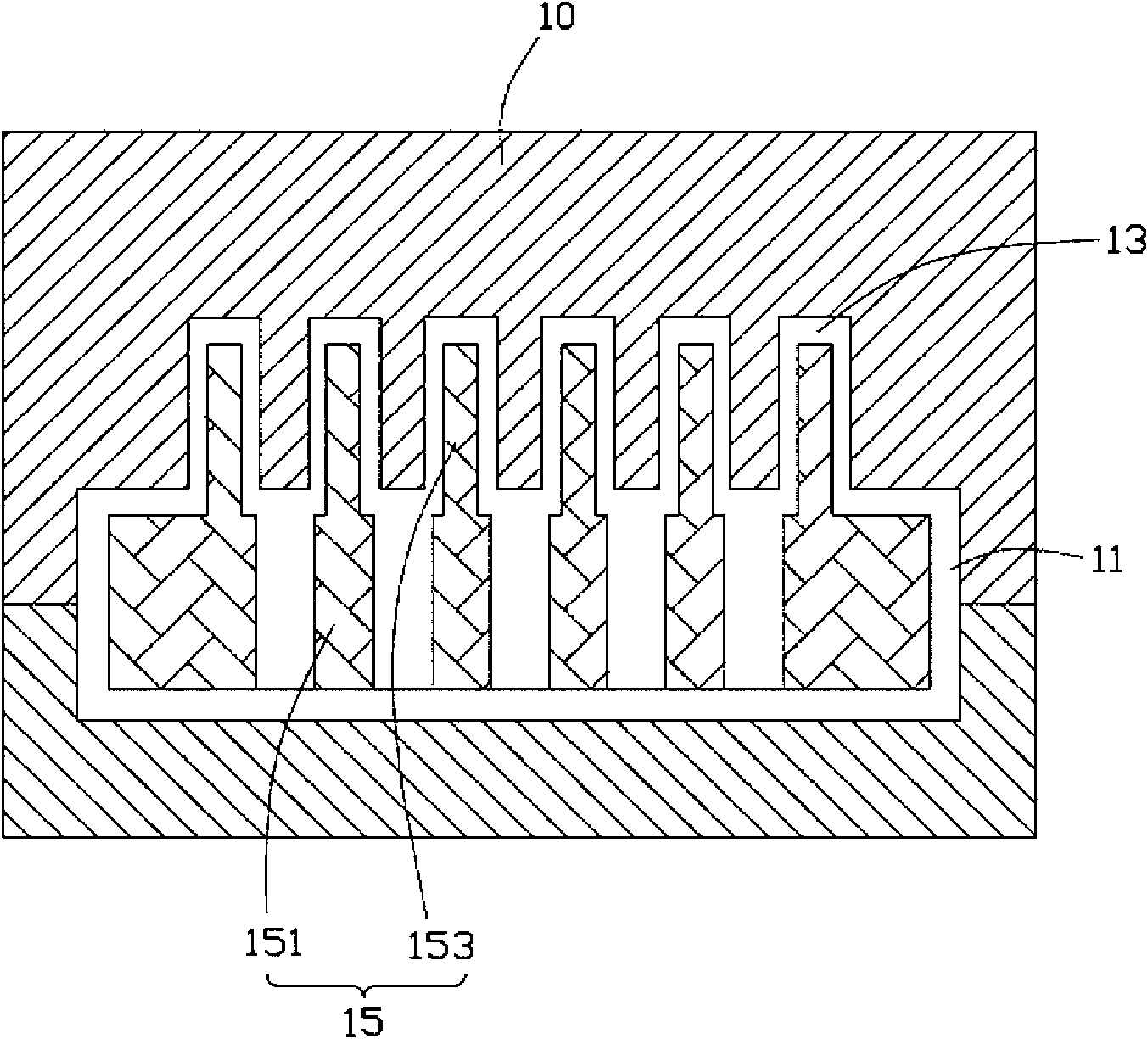

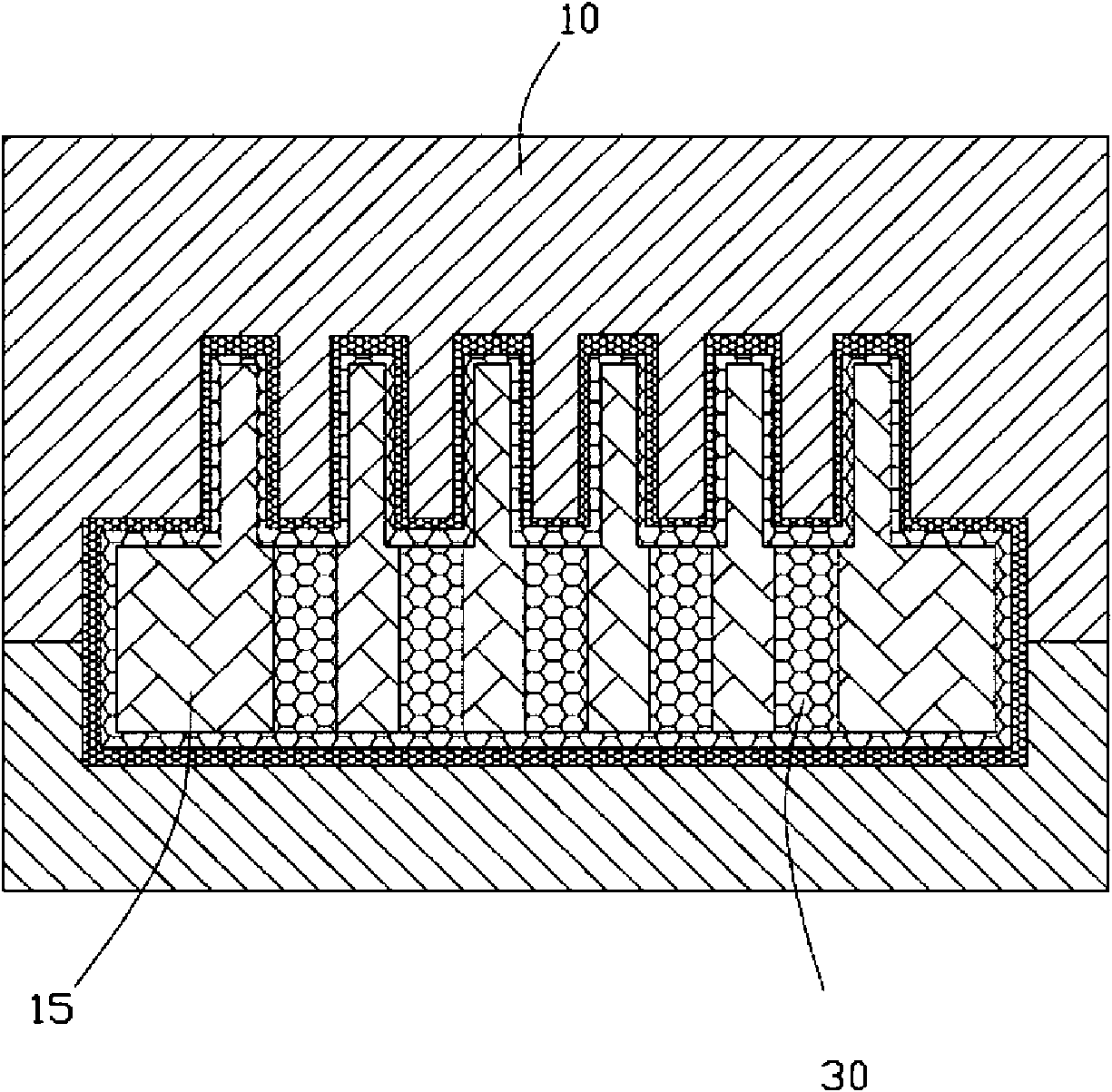

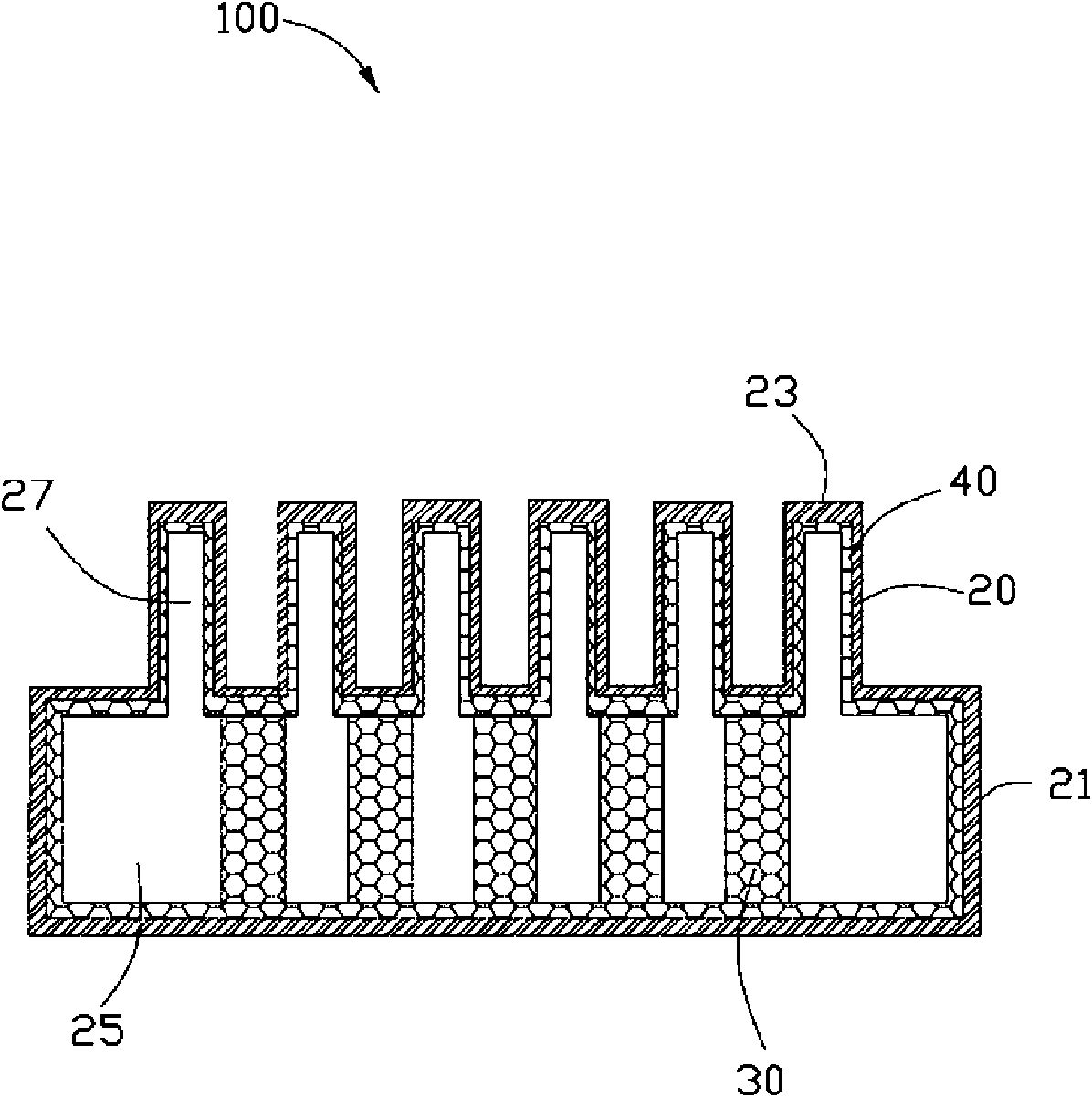

[0023] Figure 1 to Figure 3 Shown is a flat heat pipe 100 according to a first embodiment of the present invention. The flat heat pipe 100 is made by powder injection molding technology, and the specific steps are as follows:

[0024] (1) A mold 10 is provided, and the mold 10 has a first cavity 11 and six second cavities 13 located in the upper middle of the first cavity 11 and communicating with it, arranged at equal intervals. The shape of the cavity jointly formed by the first and second mold cavities 11 and 13 is equivalent to the outer dimension of the flat heat pipe 100 . It can be understood that the shapes of the first cavity 11 and the second cavity 13 can be cuboid, cylinder or other geometric shapes, and in this embodiment, they are all cuboid.

[0025] (2) A two-color molding injection machine (not shown in the figure) is provided, and the two-color molding injection machine has two injection systems in independent directions.

[0026] (3) Provide a first meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com