Method for grinding interference-free periphery of curve surface of vane

A non-interference, grinding technology, used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of low work efficiency, low cutting line speed, short belt life, etc., to achieve high production efficiency, improve Machining accuracy and surface quality, the effect of good machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

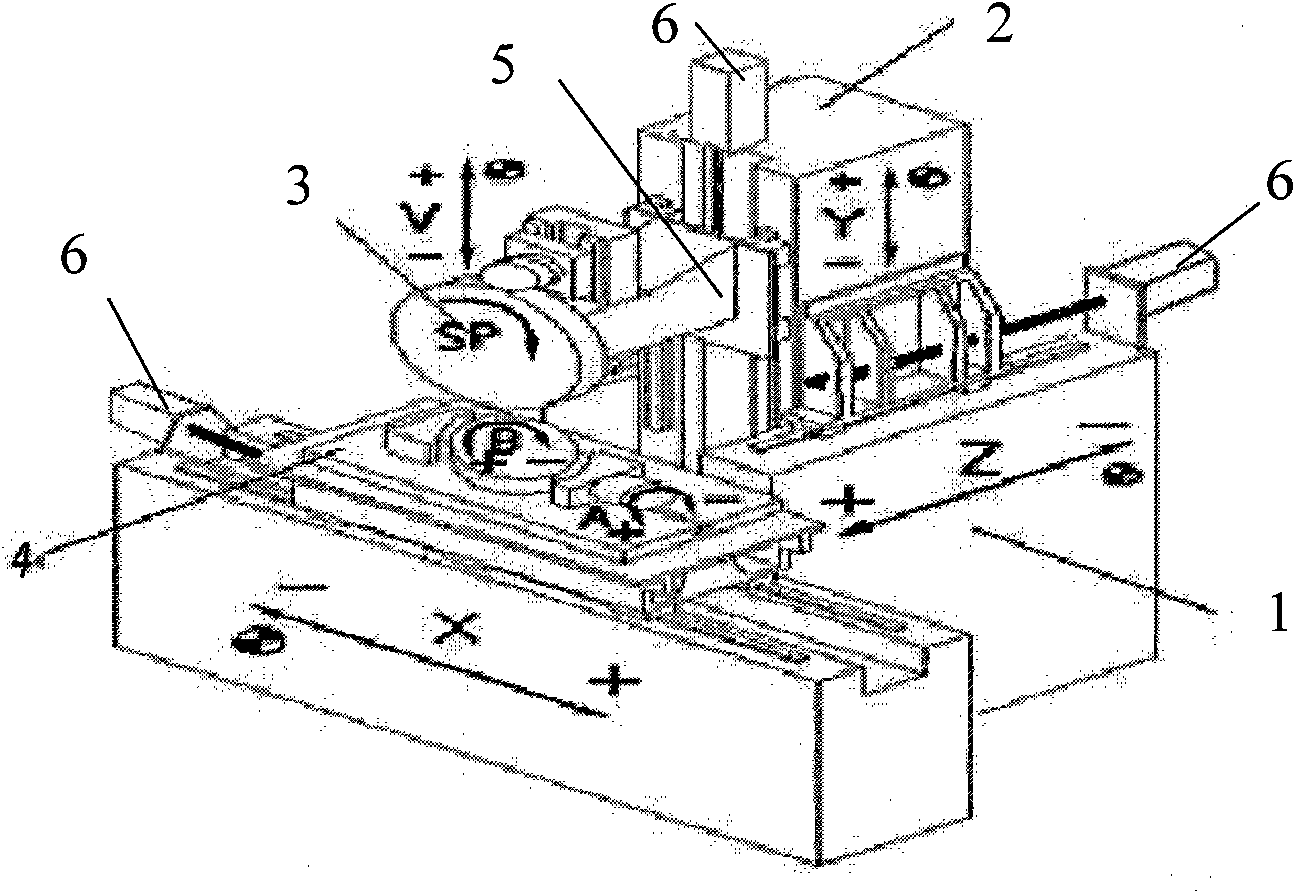

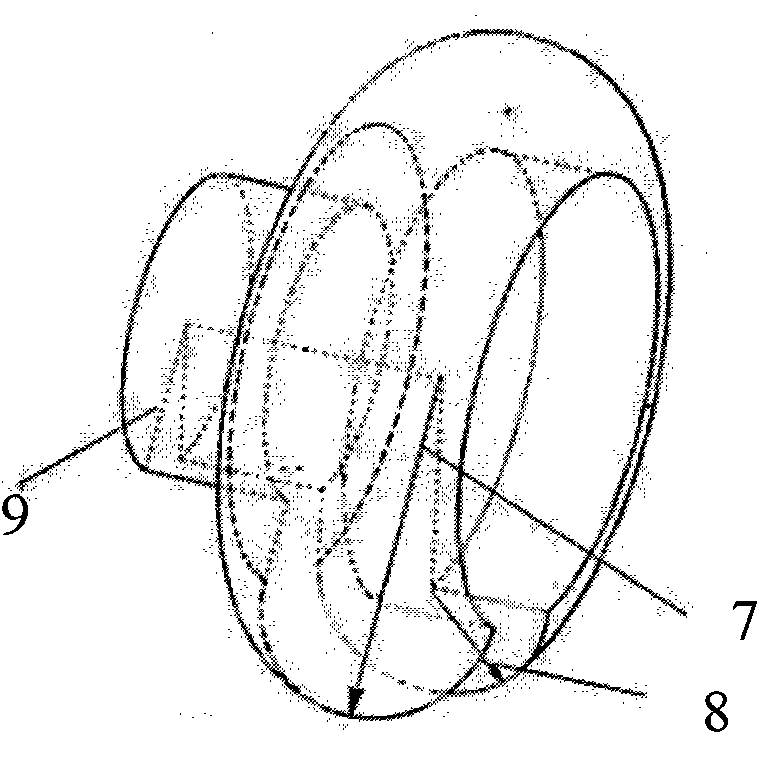

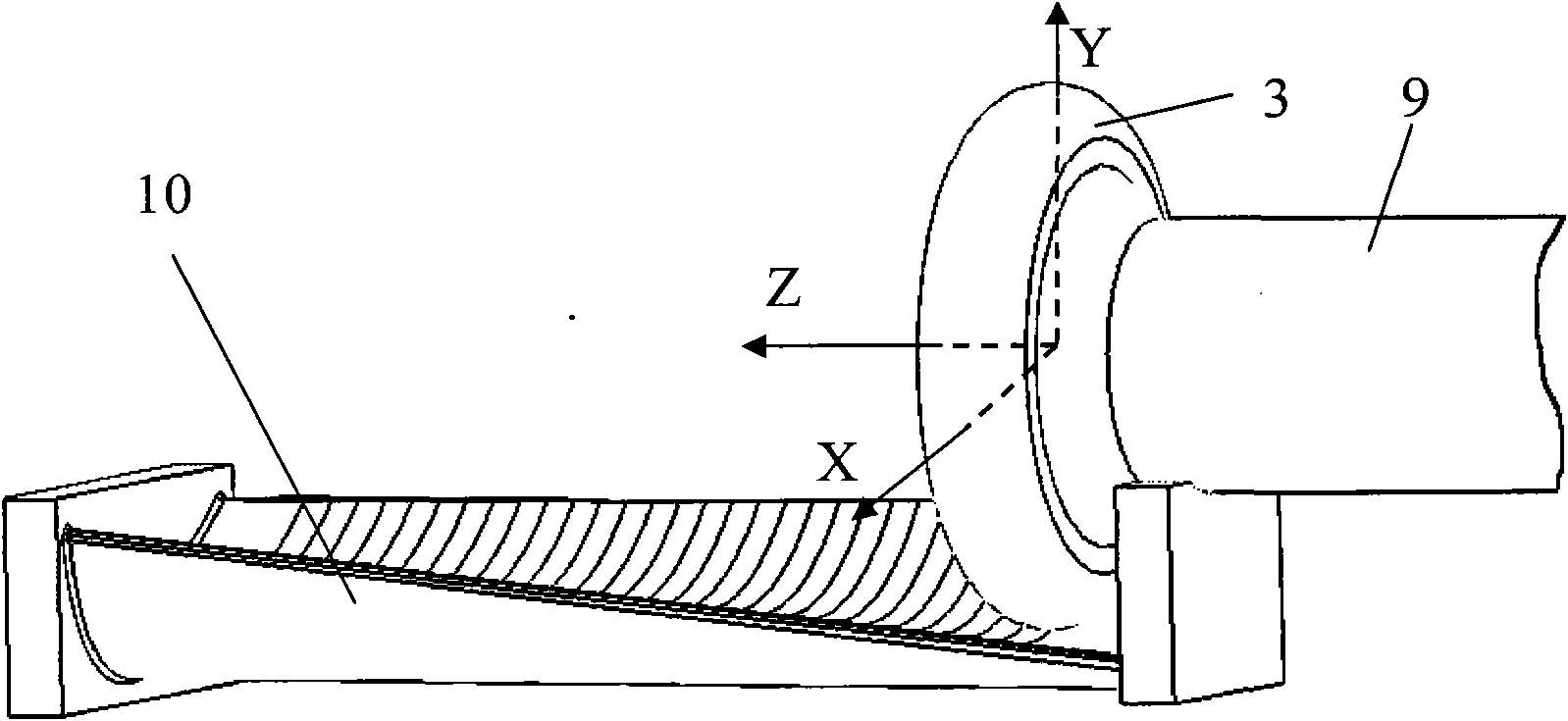

[0030] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 Shown, combined with examples to illustrate the grinding process and principle:

[0031] In this embodiment, the grinding process of a 100mm twisted blade inner arc grinding wheel is taken as an example. It is divided into N sections with equal parameters from the blade root to the blade crown along the blade height direction, and each section line is divided into M uniformly distributed processing points, which are set according to the accuracy requirements. The value of M and N. N determines the processing line spacing, and M affects the processing feed. Data such as the coordinate value of each processing point, the unit normal vector, and the radius of curvature of each point are obtained through the program.

[0032] Step 1: The axis of the blade 10 is clamped along the Z-axis direction, and the root part of the blade is far away from the column and the grinding wheel, so that the installation can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com