Thixotropic soybean oil paint and preparation method thereof

A soybean oil and paint technology, applied in the field of paint, can solve problems such as being unsuitable for factory production, and achieve the effect of facilitating factory production, meeting individual requirements, and reducing the number of construction passes

Active Publication Date: 2011-01-12

濮阳展辰新材料有限公司

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The first object of the present invention is to overcome the disadvantage that ordinary vegetable oils such as wood wax oil on the market are

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

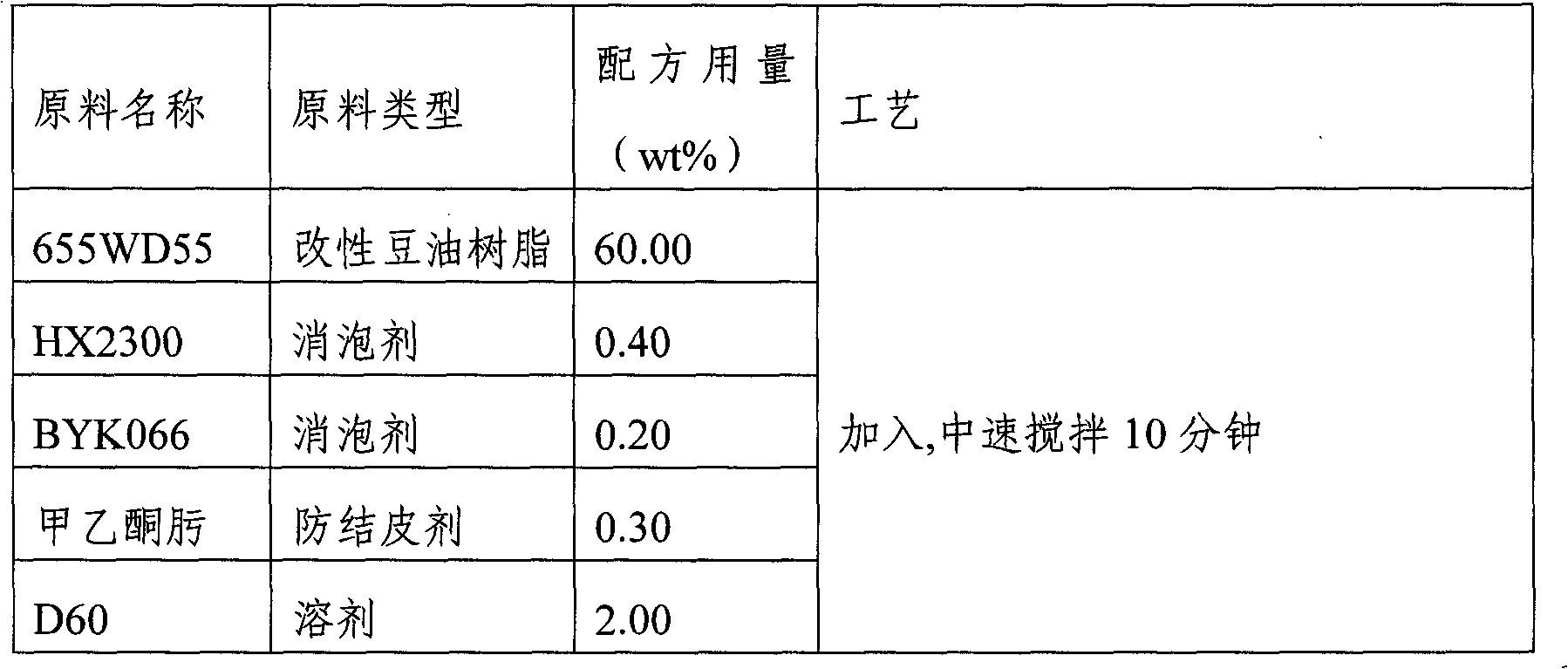

Embodiment 1

[0027] Embodiment 1: the preparation of a kind of transparent summer with thixotropic soybean oil paint

[0028]

[0029]

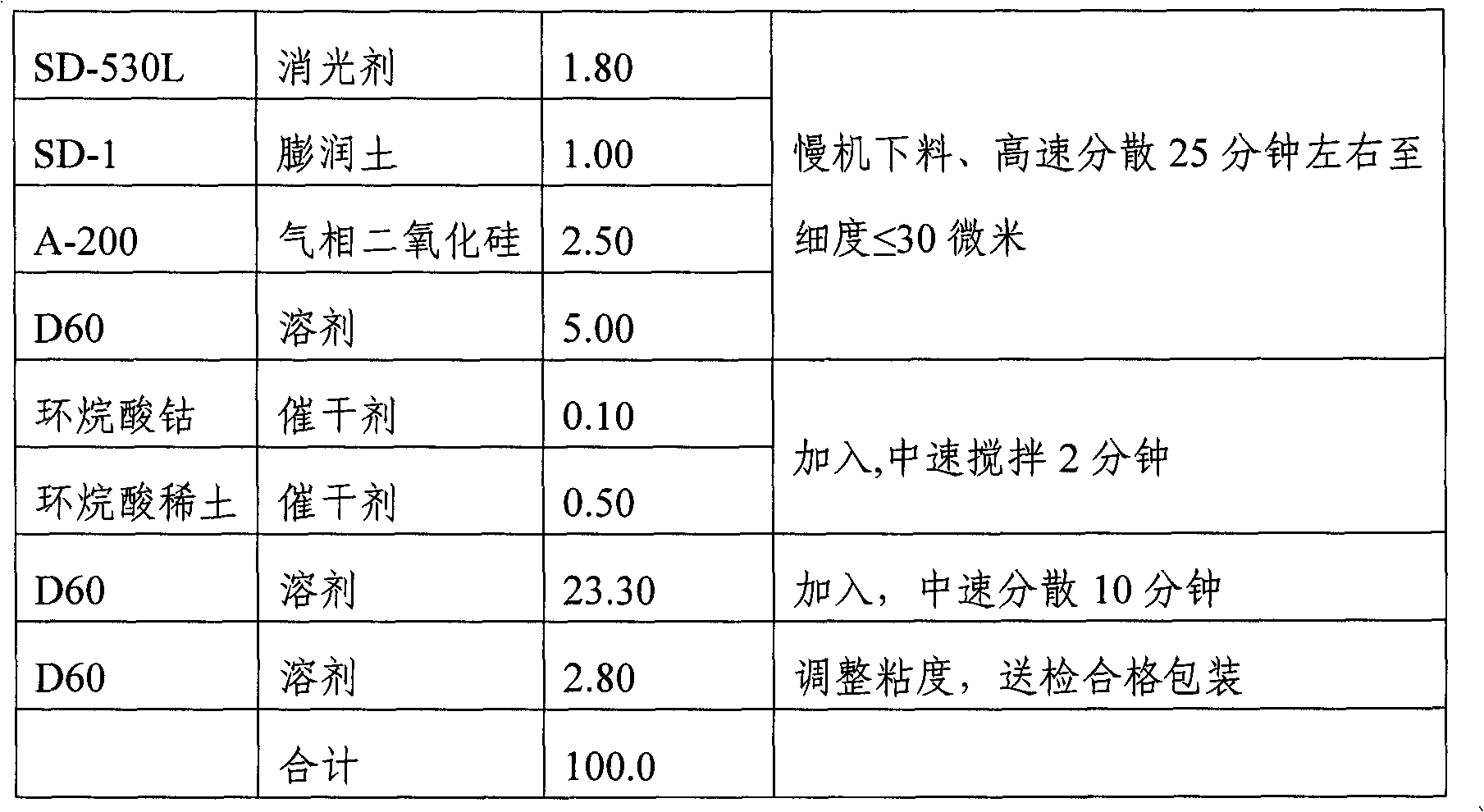

Embodiment 2

[0030] Embodiment 2: the preparation of a kind of transparent summer with low odor thixotropic soybean oil paint

[0031]

Embodiment 3

[0032] Embodiment 3: the preparation of a kind of transparent winter thixotropic soybean oil paint with low odor

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention provides a thixotropic soybean oil paint, which is prepared by mixing the following raw materials in percentage by weight: 55%-65% of modified soybean oil resin, 0.2%-0.8% of defoaming agent, 0.1%-0.3% of anti-skinning agent, 2.0%-3.5% of fumed silica, 1.0%-1.5% of bentonite, 0.4%-0.9% of drier, 0%-1.8% of flatting agent, 20%-35% of nonbenzenoid organic solvent and 0%-15% of raw pigment materials. The thixotropic plant oil paint has the advantages of good permeability, favorable adhesive force, quick drying, high solid content, high sag resistance of a vertical surface, low smell and no toxicity. The thixotropic soybean oil paint can be used for both fully-enclosed coating and open coating, and the product conforms to national standards and laws and regulations for exportingto USA and European Union.

Description

technical field [0001] The invention relates to a coating, in particular to a thixotropic soybean oil coating and a preparation method thereof. Background technique [0002] With the development of the economy, people are exposed to more and more chemical substances, and many people want to return to nature. There is such a trend in the current high-grade wooden windows or furniture coatings. More and more people hope to get Coating products are made using natural vegetable oils. At present, many manufacturers use tung oil or wood wax oil to prepare coating products, but the drying speed is slow, the weather resistance is not strong, the appearance viscosity is high, and it can only be rubbed, not suitable for spraying; even if the tung oil and wood wax oil are diluted with a solvent To adapt to spraying, but there will be sagging in the process of spraying non-planar plates, which cannot adapt to industrial production. At the same time, there is not much room for product g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C09D175/04C09D7/12C09D5/04

Inventor 陈冰陈寿生

Owner 濮阳展辰新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap