Method for regenerating rare earth trichromatic fluorescent powder for lamp

A fluorescent powder and three primary colors technology, applied in chemical instruments and methods, luminescent materials, recycling technology, etc., can solve the problems of high recycling cost, direct recycling and regeneration of less fluorescent powder, and no recycling and reuse of rare earth phosphors, etc. Achieve good regeneration effect and low-cost regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

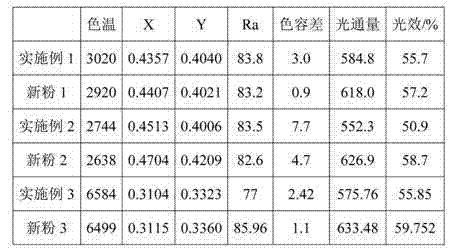

Embodiment 1

[0031] a) Wet 500g of waste fluorescent powder produced in the production process of the lamp factory and pass it through a 250-mesh sieve to remove large particles of impurities, and then magnetically separate to remove magnetic impurities to obtain recycled powder;

[0032] b) Add 100ml of acetic acid solution with a concentration of 1mol / L to the recycled powder, add water to increase the volume of the slurry to 2L, then stir for 20 minutes, then let it stand, and after the slurry is separated, pour out the upper layer of turbid liquid, and then Add 100ml of ethanol with a concentration of 95%, add water to 2L, stir for 20min, let stand, wait for the slurry to separate, pour off the upper layer of turbid liquid, then add water to 2L, heat until the water temperature is above 90°C, After stirring for 20 minutes, let it stand still, and after the slurry is layered, pour out the upper layer of turbid liquid to obtain a recovered slurry with the lower layer cleaned;

[0033] c)...

Embodiment 2

[0037] a) Take 500g of waste fluorescent powder recovered from waste lamps and remove mercury and wet through a 250-mesh sieve to remove large particles of impurities, and then magnetically separate to remove magnetic impurities to obtain recycled powder;

[0038] b) Add 100ml of hydrogen peroxide solution with a concentration of 1mol / L to the recycled powder, add water to increase the volume of the slurry to 2L, then stir for 20 minutes, then let it stand, and after the slurry is separated, pour out the upper turbid liquid, and then Add 100ml of benzene solution with a concentration of 1mg / ml, add water to 2L, stir for 20min, let stand, wait for the slurry to separate, pour off the upper layer of turbid liquid, then add water to 2L, heat until the water temperature is greater than 90 degrees Celsius Above, after stirring for 20 minutes, let it stand still, and after the powder slurry is layered, pour out the upper layer of turbid liquid to obtain a cleaned and recovered powder...

Embodiment 3

[0043] a) Take 500g of waste fluorescent powder recovered from waste lamps and remove mercury and wet through a 250-mesh sieve to remove large particles of impurities, and then magnetically separate to remove magnetic impurities to obtain recycled powder;

[0044] b) Add 100ml of hydrogen peroxide solution with a concentration of 1mol / L to the recycled powder, add water to increase the volume of the slurry to 2L, then stir for 20 minutes, then let it stand, and after the slurry is separated, pour out the upper turbid liquid, and then Add 100ml of benzene solution, add water to 2L, stir for 20min, let stand, wait for the slurry to separate, pour off the upper layer of turbid liquid, then add water to 2L, heat until the water temperature is higher than 90 degrees Celsius, and stir for 20min , stand still, and after the slurry is layered, the upper layer of turbid liquid is poured out to obtain a cleaned and recovered slurry;

[0045] c) Mill the recovered slurry for 60 minutes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com