Unit curtain wall structure capable of improving water tightness

A unitary, watertight technology, applied to walls, building components, building structures, etc., can solve problems such as unsatisfactory effects, and achieve the effect of simple structure and clear path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

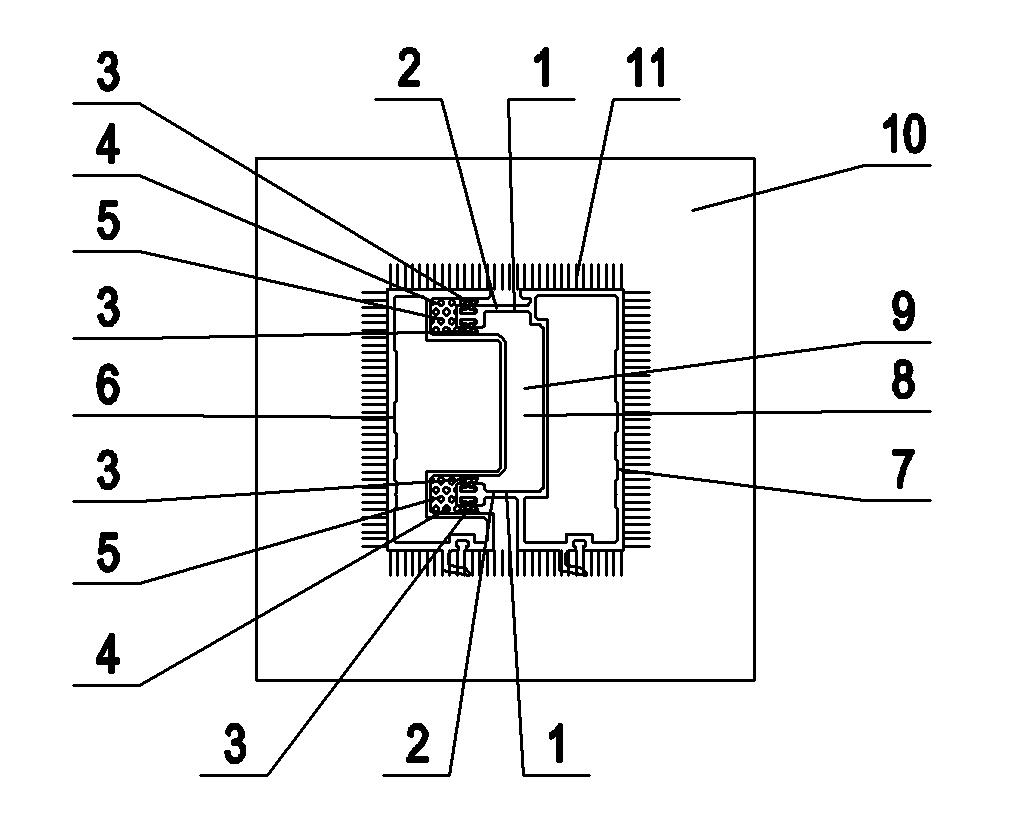

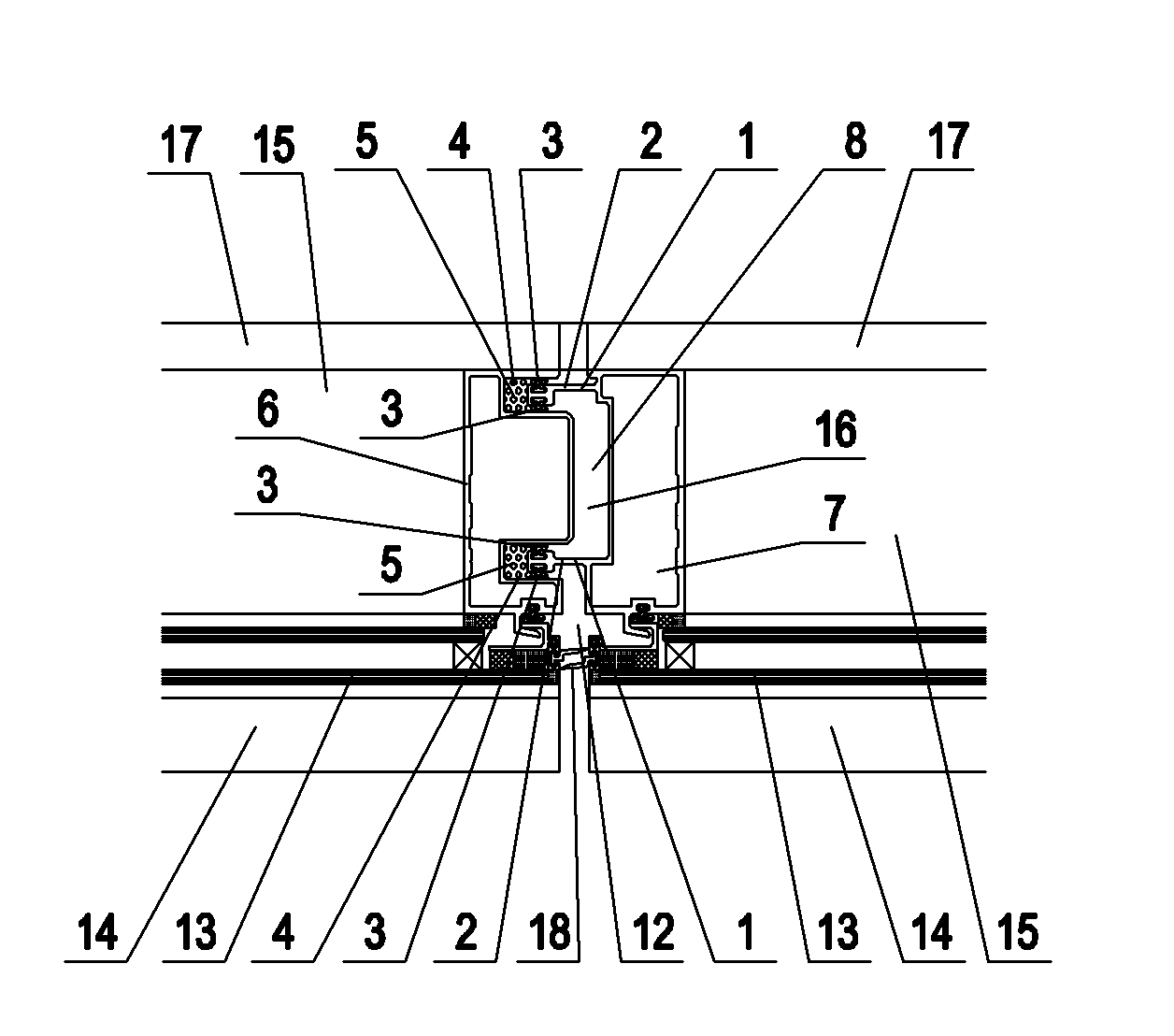

[0018] In Embodiment 1, no water is injected into the water guiding cavity 8, and the pressure inside the water guiding cavity is equal to the outside pressure at this time, and the water guiding cavity 8 can be regarded as an isobaric cavity.

Embodiment 2

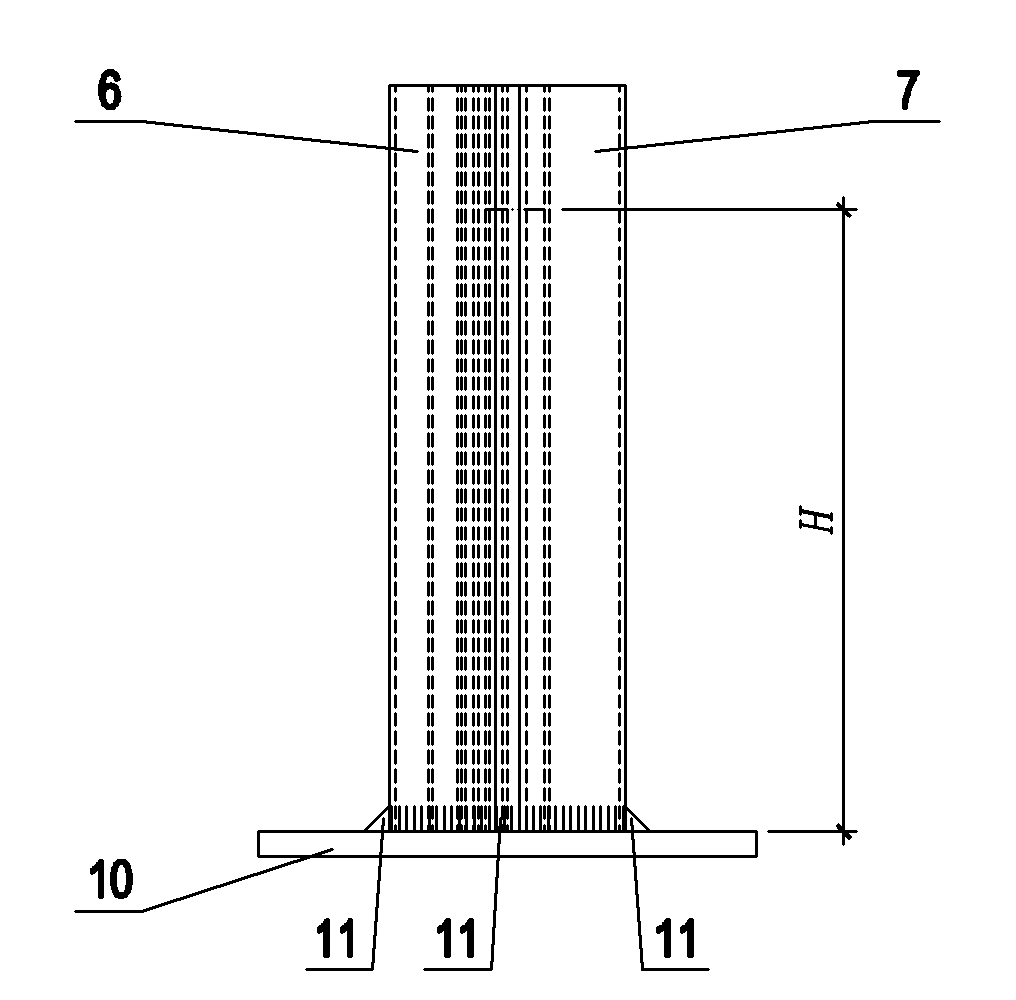

[0019] Embodiment 2, change the water-stop sponge 4 in the groove 5 into a sealant 11, the side and bottom surface of the water-guiding cavity meet the water-tight requirements, slowly pour water into the upper mouth of the water-guiding cavity 8, when When the height of the experimental water 9 reaches H, the water pressure in the water guiding cavity P=HD (D is the specific gravity of the experimental water 9), at this time, the pressure in the water guiding cavity is greater than the pressure outside, and the pressure is not equal to the outside, and the leading The water cavity 8 becomes a cavity with hydraulic pressure.

Embodiment 3

[0020] Embodiment 3, drill a drainage hole on the sealing plate 10 for the experiment, drain the experimental water 9 in the water guiding cavity 8, and slowly pour water in the upper mouth of the water guiding cavity 8, and the water will flow from the experiment Use the drainage holes on the sealing plate 10 to flow out. When the water intake ≤ discharge volume, no water will accumulate in the water guide cavity 8. At this time, the water guide cavity 8 is still an equal pressure cavity. When the water intake > discharge volume, the water guide Water will slowly accumulate in the cavity 8 to form a water pressure P. At this time, the pressure in the water-guiding cavity is greater than the outside pressure, which is not equal to the outdoor pressure, and the water-guiding cavity 8 becomes a cavity with hydraulic pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com