Recooler for mine

A recooler and mine-used technology, applied in mining equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of unfavorable recycling, large water demand, and easy water pollution, so as to facilitate transportation and heat exchange Large volume and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

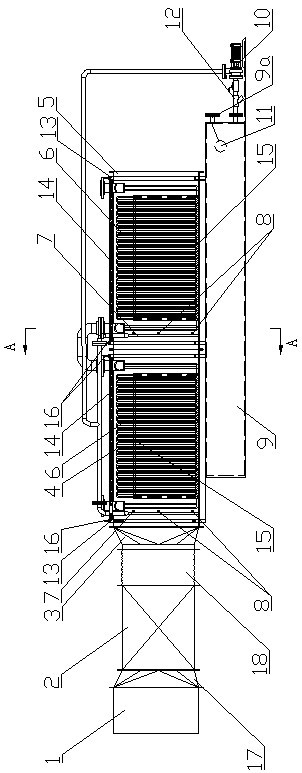

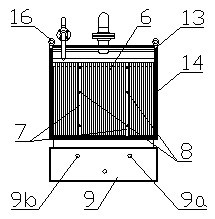

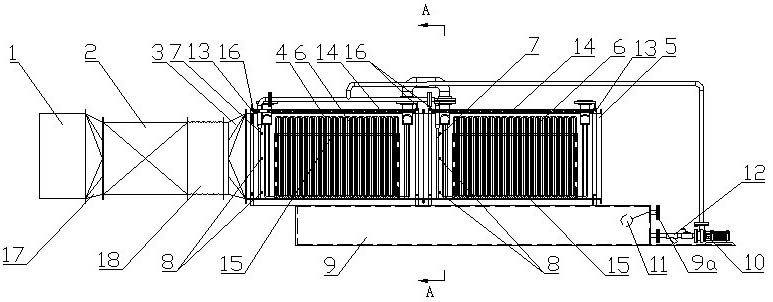

[0028] figure 1 is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A-A cross-sectional view, as shown in the figure: the mine recooler of this embodiment includes a filter 1, a mine counter-rotating axial flow local fan 2, an air inlet 3, a heat exchange chamber 4, an air outlet 5 and a set of The heat exchange coil 6 used for heat exchange between cooling water and air in the heat exchange chamber 4. The heat exchange coil is made of φ16×1mm copper tubes, with 50 surface tubes and 37 rows, bent into a serpentine shape, and the air flow is uniform. It flows through the heat exchange coil, the contact area is large, and the heat exchange effect is good. Connected in sequence, the mine recooler also includes a spray device, the spray device includes two spray water pipes 7 and 12 atomizing nozzles 8 arranged on the spray water pipes 7, the atomizing nozzles 8 It is located in the heat exchange chamber 4, and its injection port faces the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com