Grease filling pipe device

A technology of grease and grease tanks, which is applied in the field of grease filling tools, can solve the problems of gelatinous grease with poor viscosity, poor fluidity, obstacles in the production process, and slow loading speed, so as to achieve less failure and great economic and social benefits , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

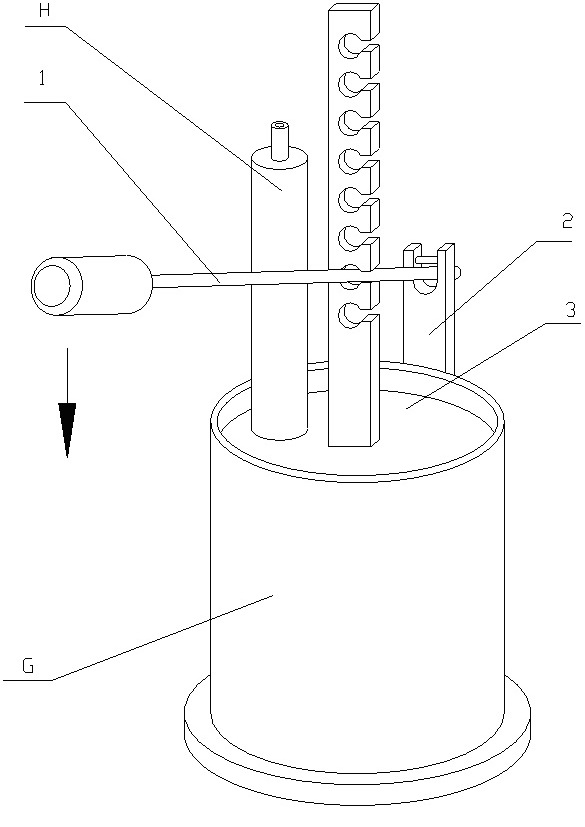

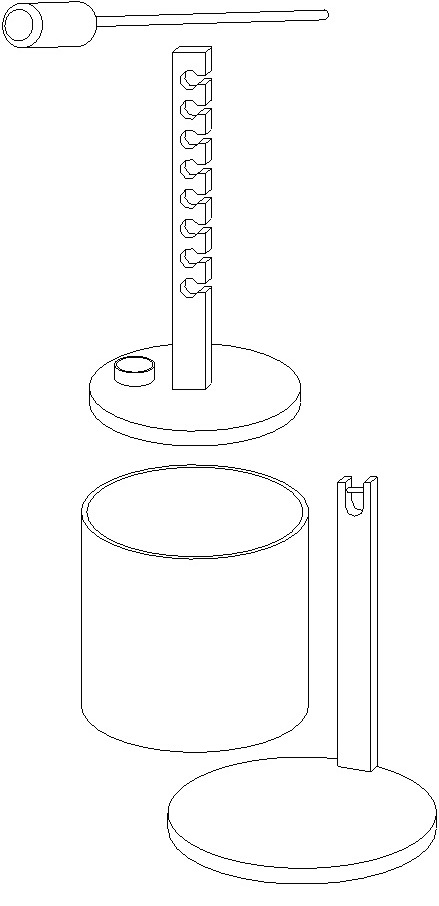

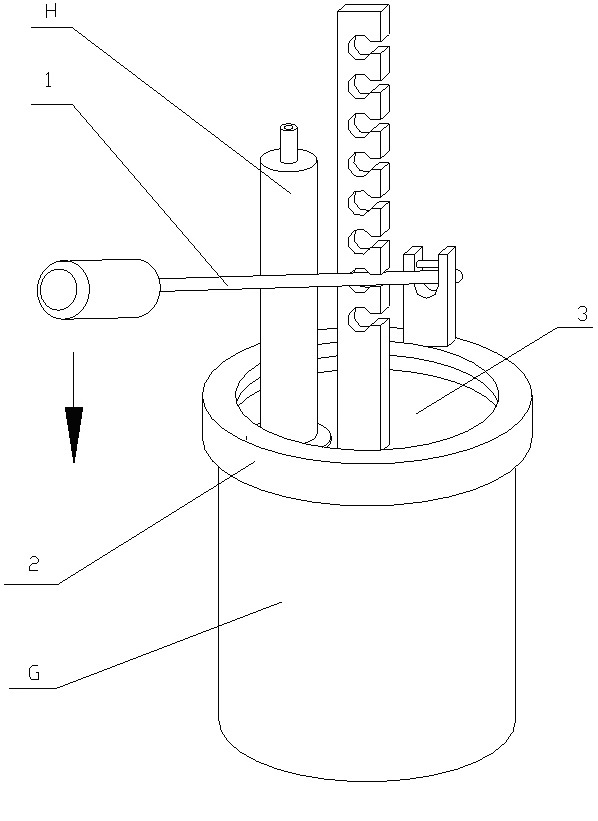

[0031] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] A grease pipe loader, in which a pry seat 2 with a pry hole is arranged on the side of an open grease tank G; a movable pressure plate 3 is placed in the grease tank G;

[0033] Described moving platen 3 is to vertically fix a porous strip plate 3a that offers a plurality of holes on the long strip plate on the circular piston plate 3c, and offers a round hole on the piston plate 3c, set on the round hole Intubation sleeve 3b;

[0034] The skid seat 2 is a pry hole rod 2b with a pry hole fixed on the bottom plate 2c, or the skid seat 2 is fixed on the ring-shaped cover ring 2a at the opening of the grease tank G. Pry hole lever 2b, the height of the pry hole is higher than the opening of the grease tank G; one of the two structures of the pry seat 2 can be selected.

[0035] Rod-shaped pry bar 1 passes through a hole of the porous st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com