Injection method for lithium battery

A lithium battery and lithium ion battery technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of reducing the limited volume of battery shells and the impact of battery safety, shortening the time of moisture contact, controlling absorption, The effect of shortening the injection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

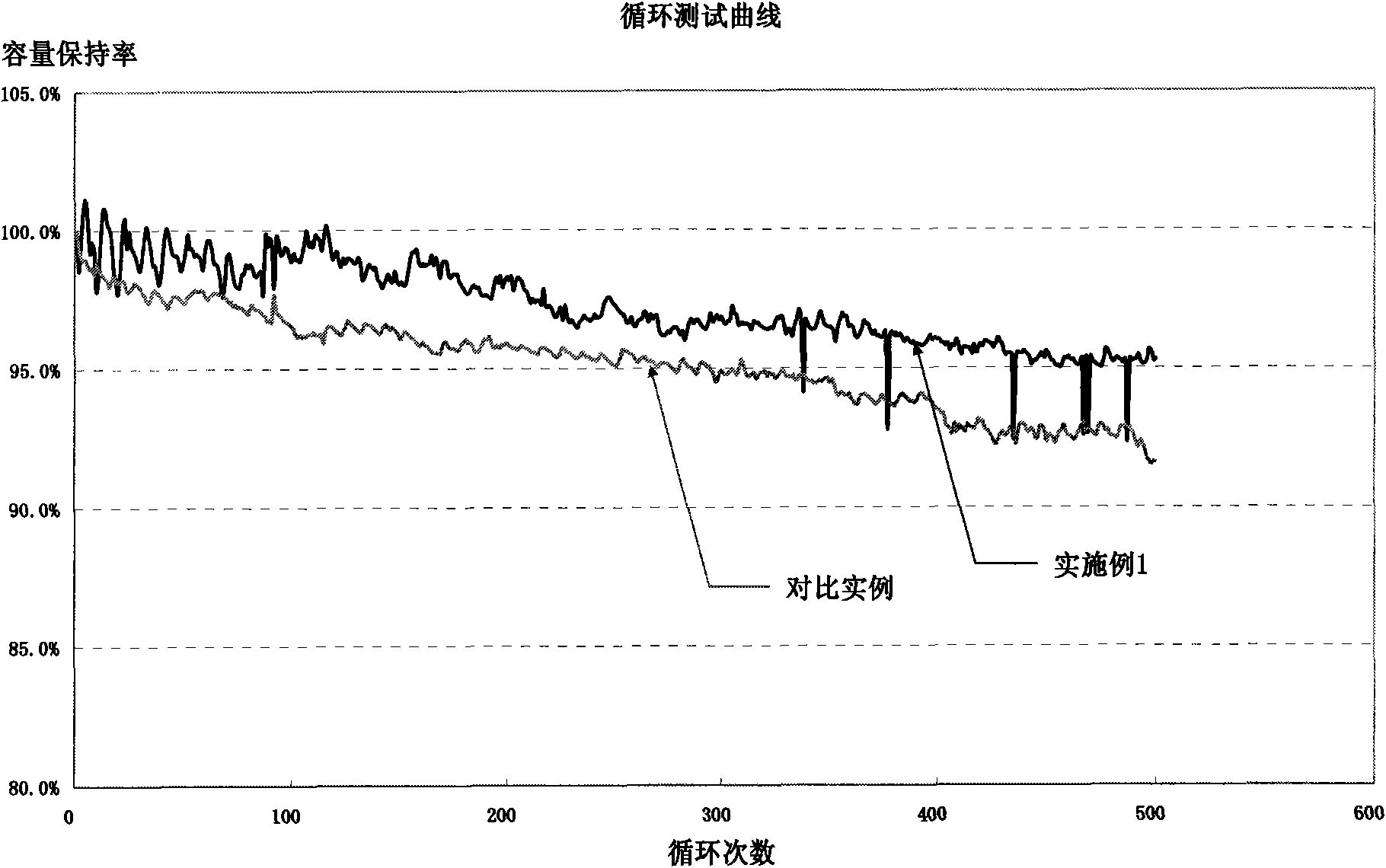

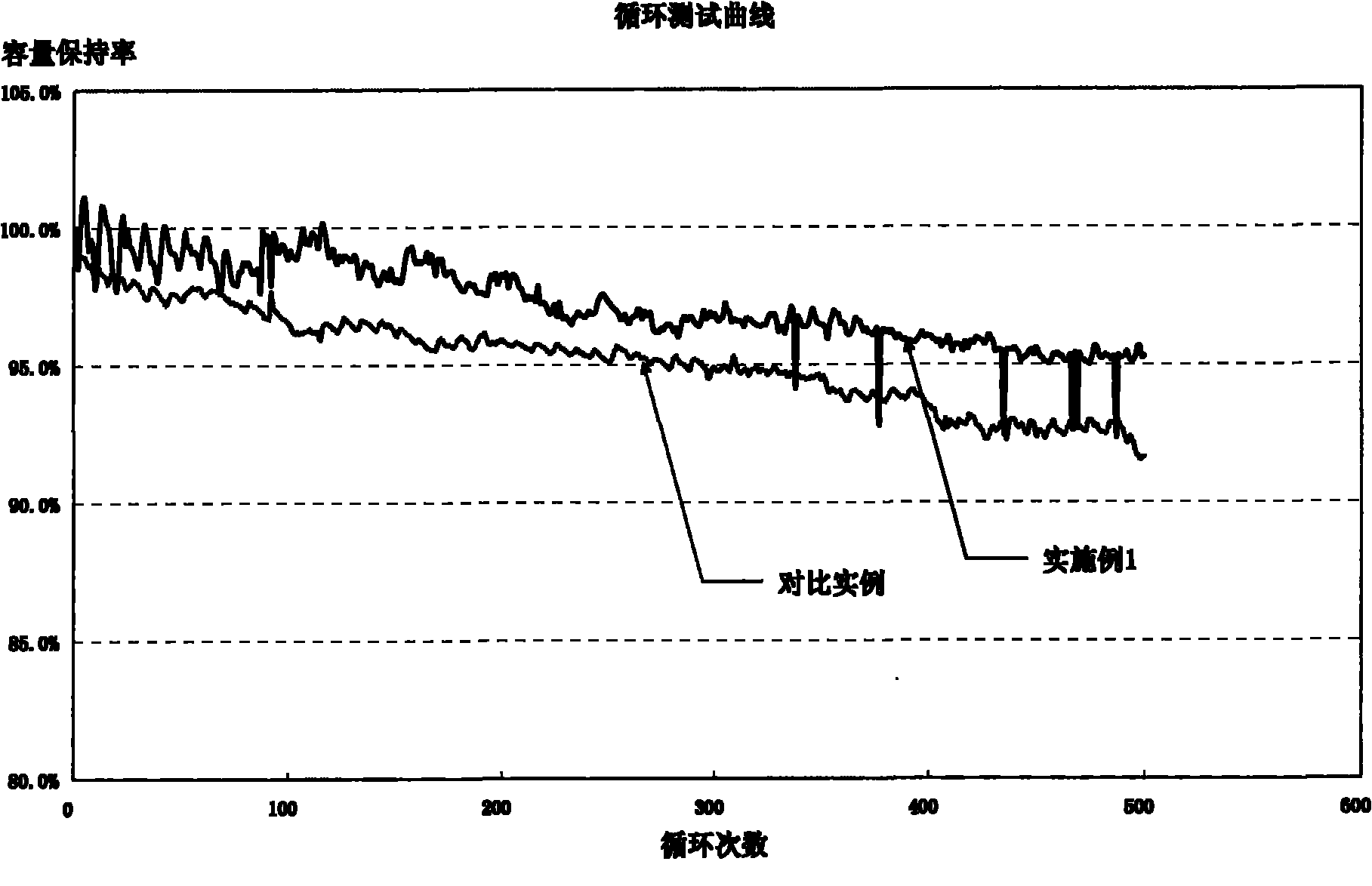

Examples

Embodiment 1

[0032] This example illustrates that the present invention provides a kind of liquid injection method of lithium-ion battery

[0033] 1. Preparation of battery

[0034] (1) Preparation of positive electrode

[0035] Mix 143 grams of positive electrode active ingredient LiFePO4, 6.4 grams of conductive agent SP, 9.55 grams of binder polyvinylidene fluoride PVDF, and 262 grams of N-methylpyrrolidone, and then stir in a vacuum mixer to form a uniform positive electrode slurry.

[0036] The slurry is evenly coated on 18um aluminum foil, then dried at 120°C, rolled, and cut into strips to obtain a positive electrode with a size of 1540×55×0.167mm, which contains 26.4 grams of active components LiFePO4 (lithium iron phosphate) .

[0037] (2) Preparation of negative electrode

[0038] 53.2 grams of active ingredient natural graphite, 1.48 grams of acetylene black, 1.77 grams of conductive agent SP (Chinese name of SP: sodium polydisulfide dipropane sulfonate), 2.65 grams of binder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com