Cyclone desander for removing fine sand from surface water

A technology for cyclone sand removal and surface water removal, which is applied in cyclone devices, devices whose axial directions of cyclone can be reversed, etc., can solve the problems of reduced processing capacity, unsuitable application of desander equipment, occupation and other problems. achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It will be described in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the accompanying drawings and the following specific embodiments.

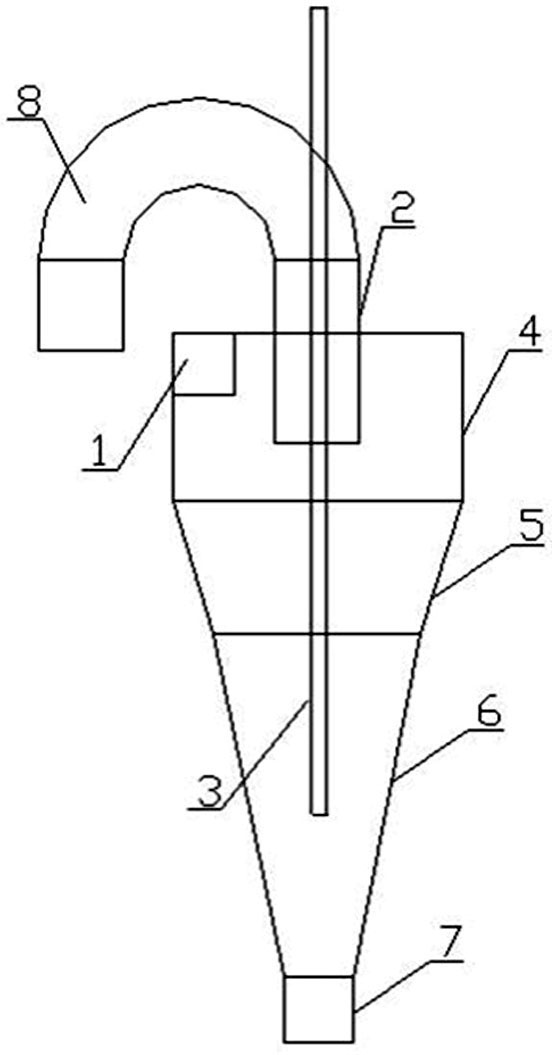

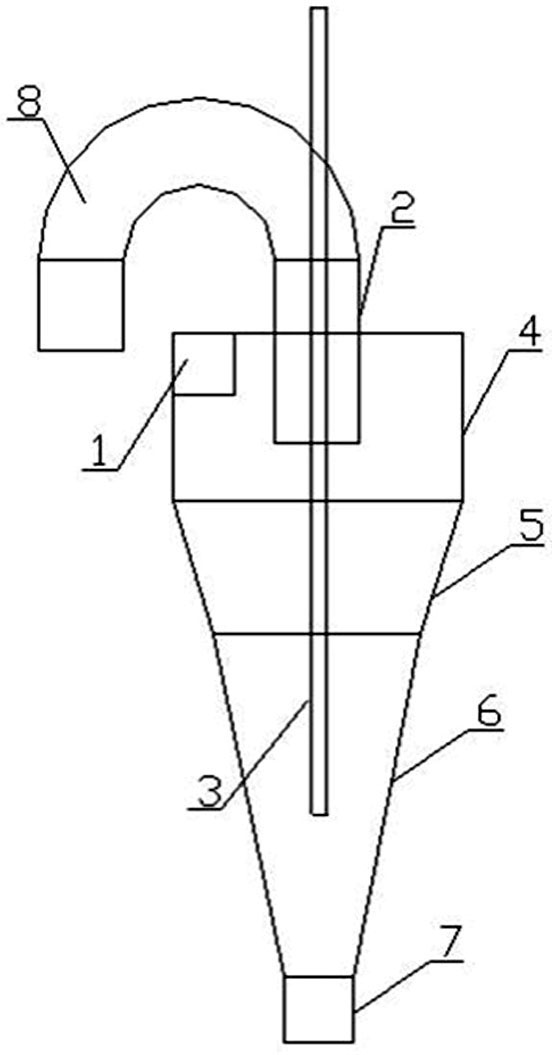

[0019] Such as figure 1 As shown, the cyclone desander includes a cavity, a feed pipe 1 , an overflow pipe 8 and an underflow pipe 7 . Wherein the cavity is composed of a cylindrical cavity 4 in the upper section, a large conical cavity 5 in the middle section and a small conical cavity 6 in the lower section. The feed pipe 1 is tangentially connected to the side wall of the upper cylindrical cavity 4, the bottom of the small conical cavity 7 of the lower segment is connected to the bottom flow tube 7, and the overflow pipe 8 is connected upwards from the center of the upper cylindrical cavity 4 . Above is the cyclone of existing general structure. The improvement of this structure lies in the addition of a central air duct 3, which is a hollow circular tube whose lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com