Numerical control plasma six-shaft five-linkage groove cutting machine

A five-link, plasma technology, used in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting cutting accuracy and difficult to adjust the cutting torch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

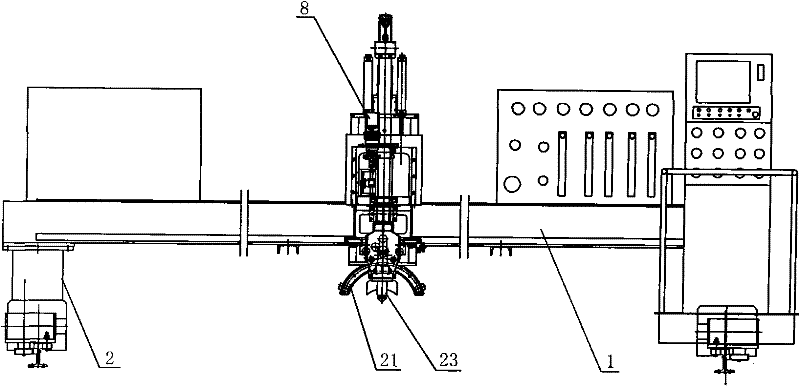

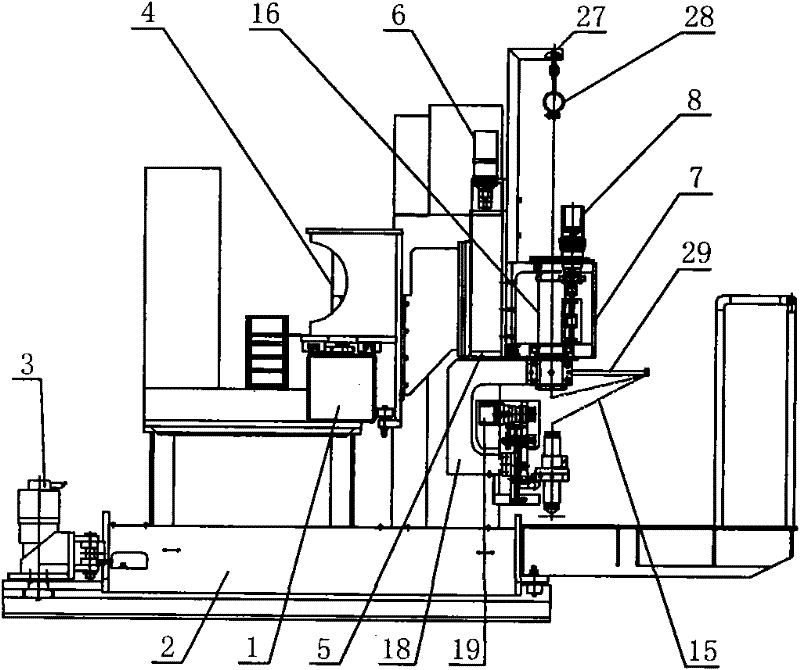

[0016] Depend on figure 1 , figure 2 with image 3 It can be seen that the CNC plasma six-axis five-link bevel cutting machine of the present invention includes a beam 1, and end frames 2 are installed on both sides of the beam 1, and the two ends of the frame are connected with a longitudinal movement device, and the longitudinal movement device is placed on the track and is driven by a longitudinal movement motor. 3 drive, the lateral moving device is installed on the crossbeam 1 and driven by the lateral moving motor 4, the main engine is connected with the lifting moving device through the bracket 5, and the lifting moving device is driven by the lifting moving motor 6 and connected with the lateral moving device.

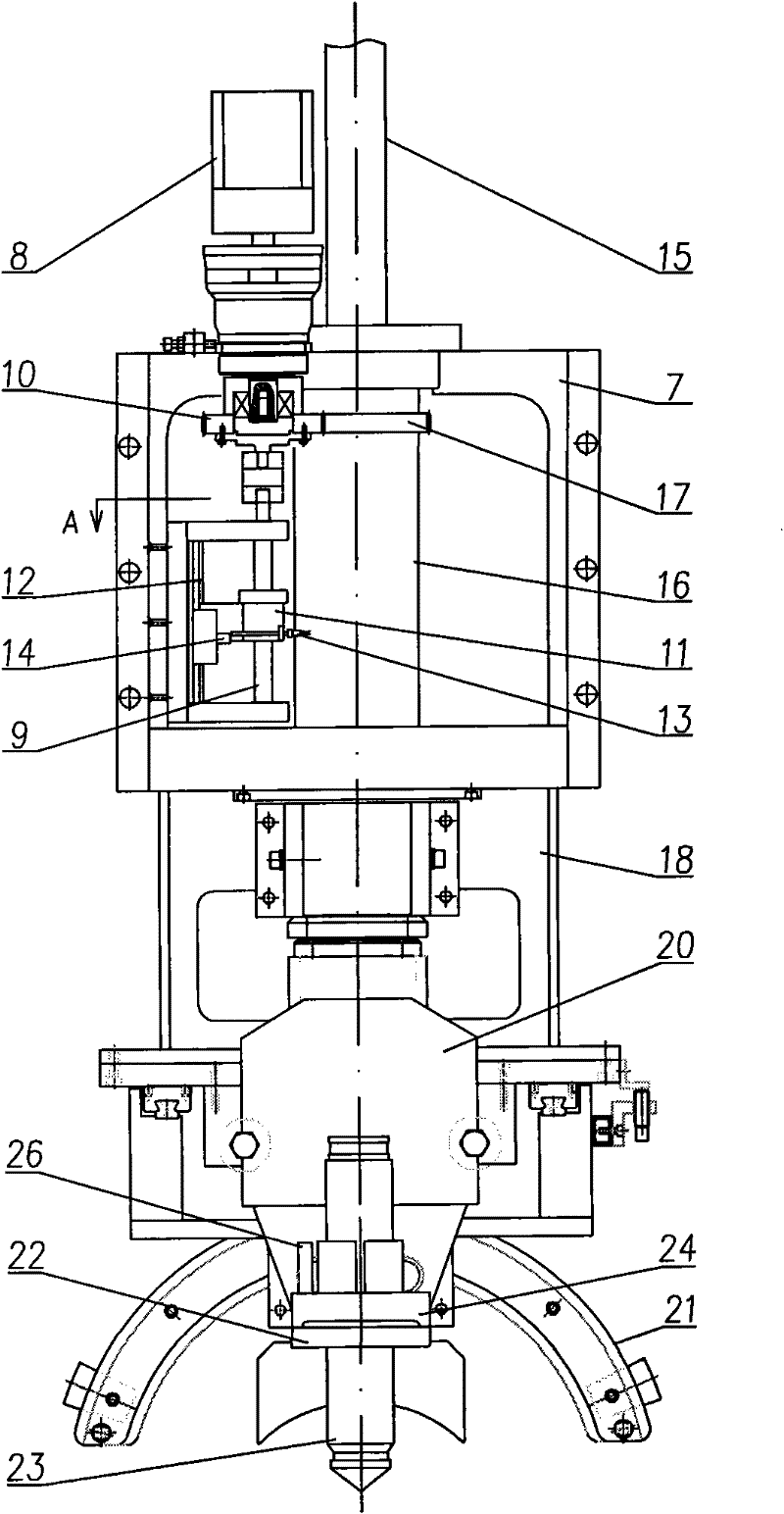

[0017] see Figure 4 with Figure 5 , the main engine includes a rotary device, the cabinet 7 of the rotary device is installed on the bracket 5, the rotating motor 8 is installed on the top of the cabinet 7, the output shaft of the rotary motor 8 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com