PU hydrolyzed bubble film for treating pollution on rivers and lakes

A bubble film, hydrolyzable technology, applied in water pollutants, energy wastewater treatment, biological water/sewage treatment, etc., can solve problems such as water quality deterioration and biodiversity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

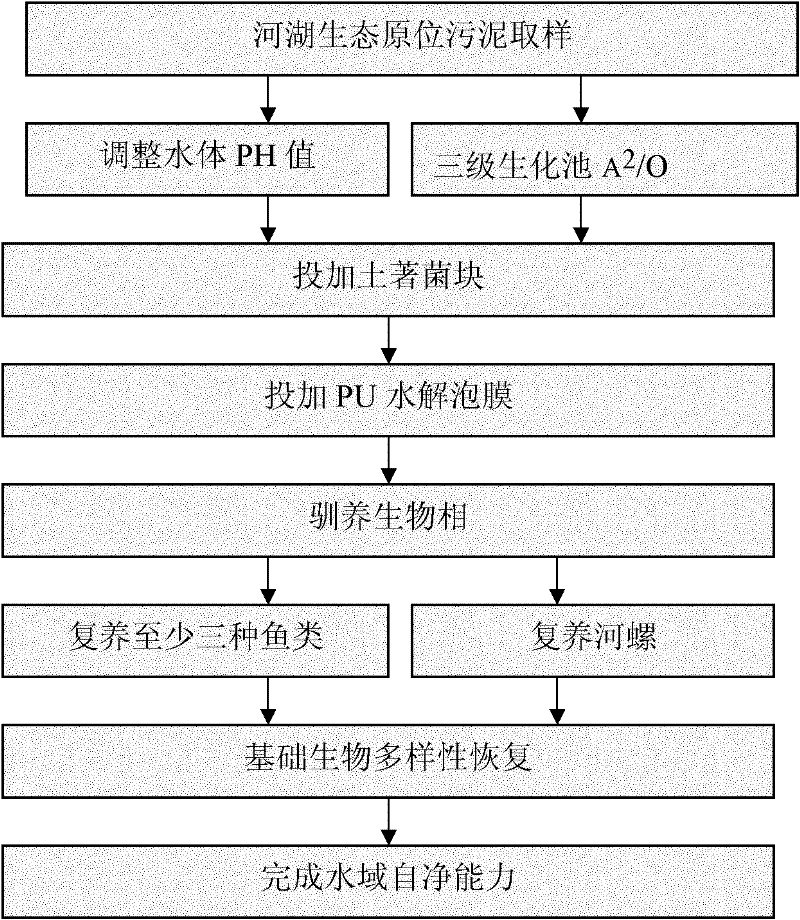

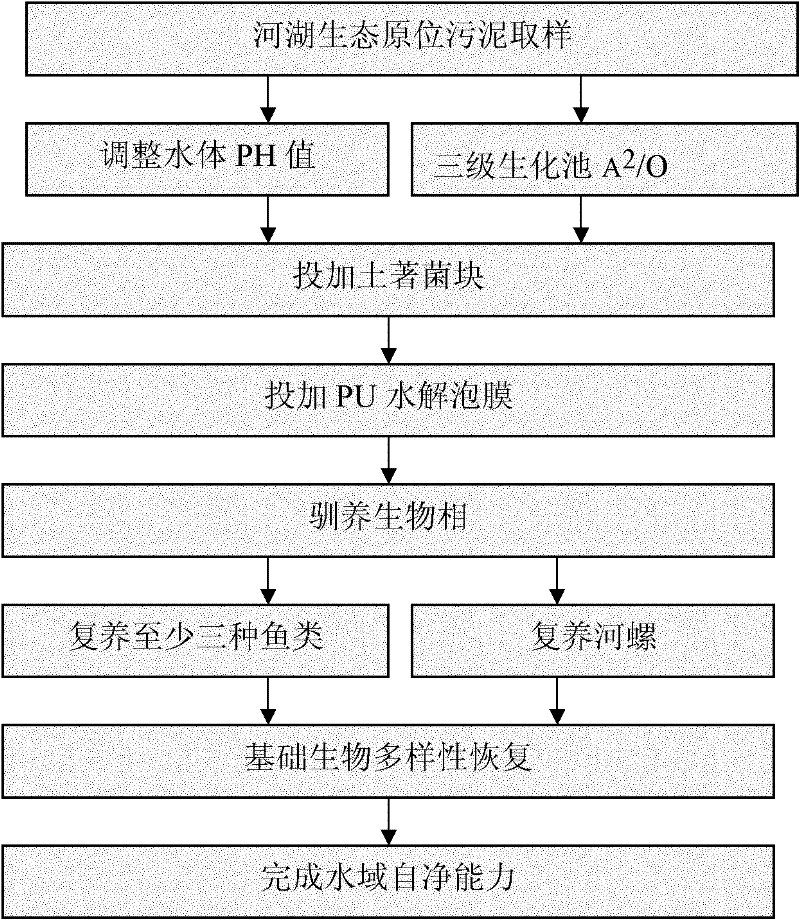

Method used

Image

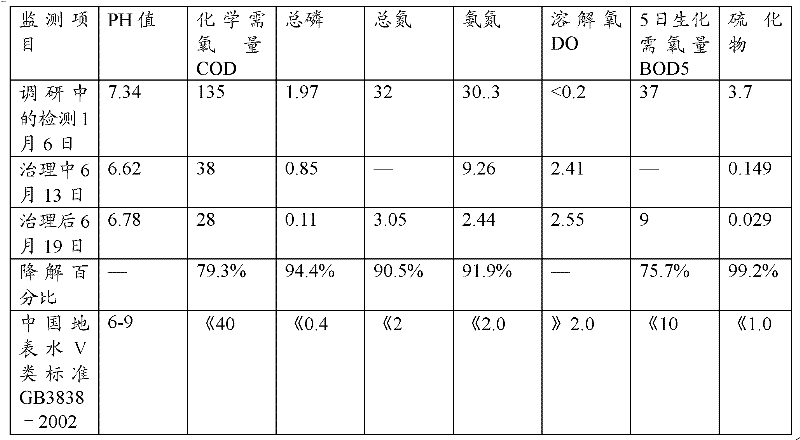

Examples

Embodiment 1

[0013] 14% by weight of the indigenous bacteria promotion preparation, 11% by weight of the aquatic biological promotion preparation, 2% by weight of natto plant polysaccharide kinase and 73% by weight of the hydrolyzable PU material are mixed uniformly and then foamed in the mold. A PU hydrolyzed foam film was prepared. Indigenous bacteria promotion preparations can be nutrient sources such as glucose, flour, sugar, compound herbal extracts or plant polysaccharides; water biological promotion preparations, such as glucose, flour, milk powder, sugar, etc.; hydrolyzable PU materials can be made of 55% by weight of polyamino formate, 2% by weight of zinc oxide, 2.5% by weight of zinc, 4% by weight of stearic acid and 36.5% by weight of water.

Embodiment 2

[0015] 16% by weight of the indigenous bacteria promotion preparation, 12% by weight of the aquatic biological promotion preparation, 2% by weight of natto plant polysaccharide kinase and 70% by weight of the hydrolyzable PU material are mixed uniformly and then foamed in the mold. A PU hydrolyzed foam film was prepared.

Embodiment 3

[0017] 17% by weight of the native bacteria promotion preparation, 13% by weight of the aquatic organisms promotion preparation, 2.5% by weight of natto plant polysaccharide kinase and 67.5% by weight of hydrolyzable PU material are mixed uniformly and then foamed in the mould. A PU hydrolyzed foam film was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com