Efficient, safe and environment-friendly blasting device

A technology of safety and environmental protection, injection device, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the existence of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

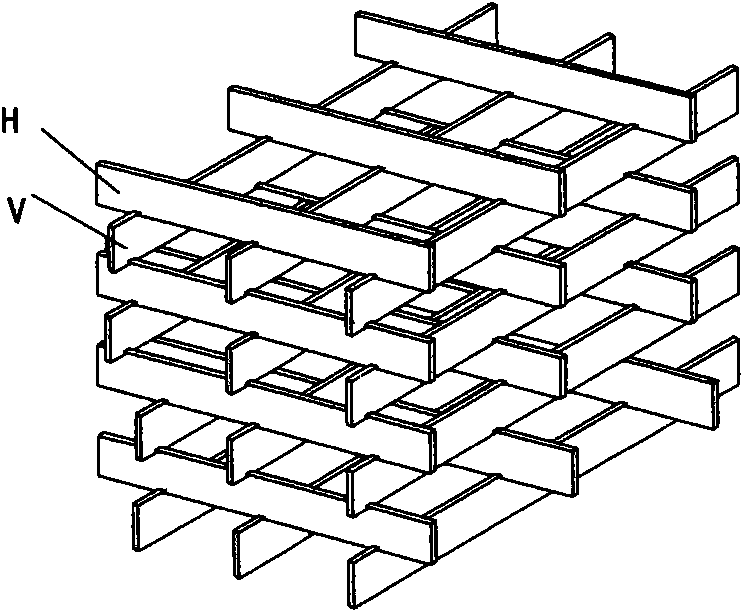

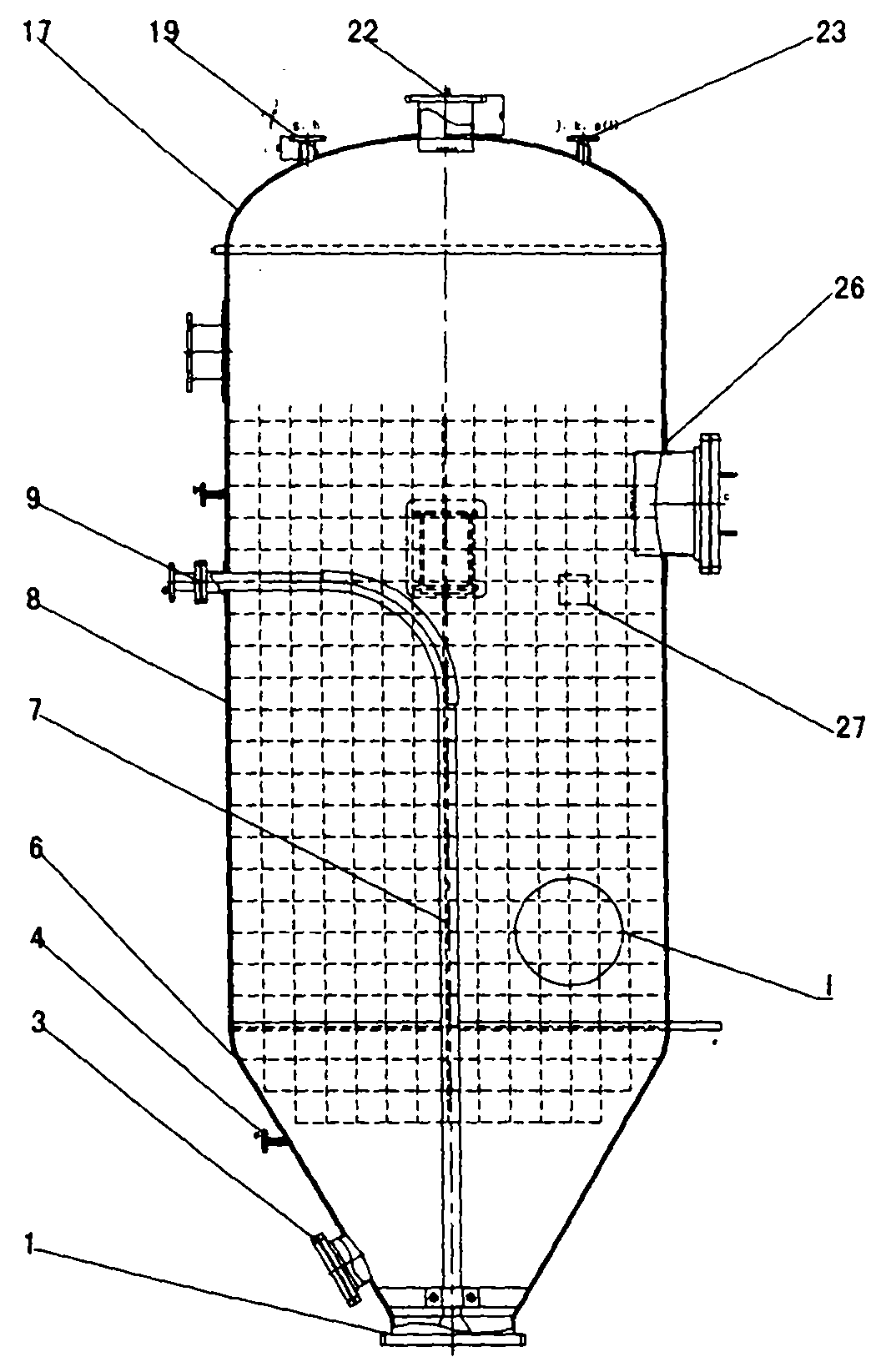

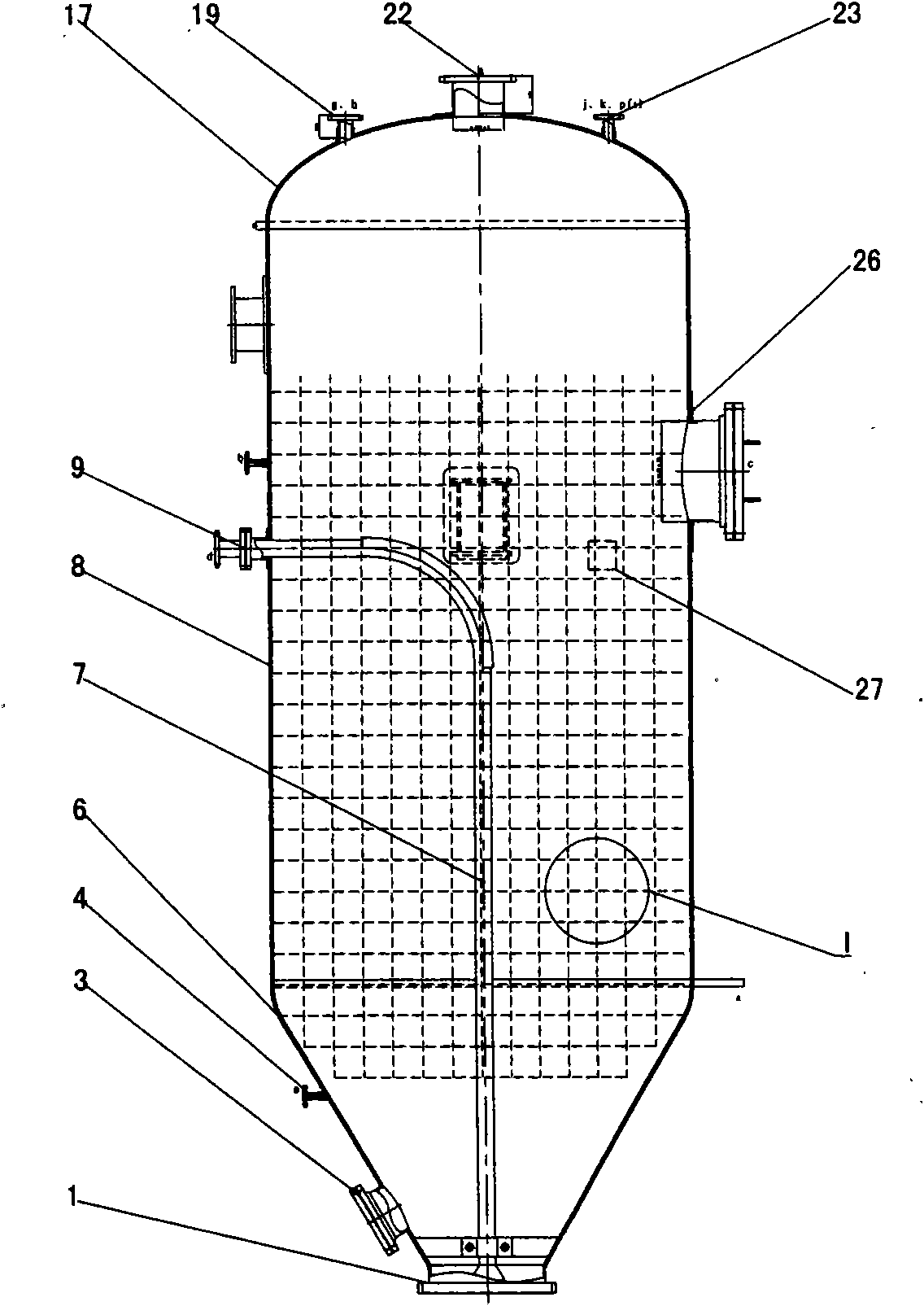

[0015] The high-efficiency environmental protection blowing device of the present embodiment is as figure 1 and figure 2 As shown, there is a tank body 8 with a feed inlet 22 and a nitrogen filling port 19 at the top 17, the lower part 6 of the tank body is tapered, and the bottom end has a fluidized plate 1, forming a fluidized bed with an external air inlet device. The tank body 8 is equipped with an inverted L-shaped discharge pipe 7. The lower end of the discharge pipe is in the shape of a gradually expanding bell mouth and is located above the fluidized plate 1 of the fluidized bed. The upper end passes through the side wall of the tank body 8 and passes through the discharge pipe. Port 9 is connected with the coal injection external pipeline. The middle part of the tank body 8 is filled with a uniform temperature labyrinth 27 . The uniform temperature labyrinth 27 is composed of criss-crossing metal strips forming a grid shape, and the specific structure is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com