Method for preparing wound heat-insulating drum

A thermal insulation tube and soft felt technology, which is applied in thermal insulation, pipeline protection, mechanical equipment, etc., can solve problems such as the difficulty of grinding and repairing the transition section of the inner and outer surfaces of the thermal insulation felt, insufficient bonding force between layers, and difficulty in releasing the stress of the thermal insulation tube. Achieve good high-temperature dimensional stability, short preparation cycle, and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

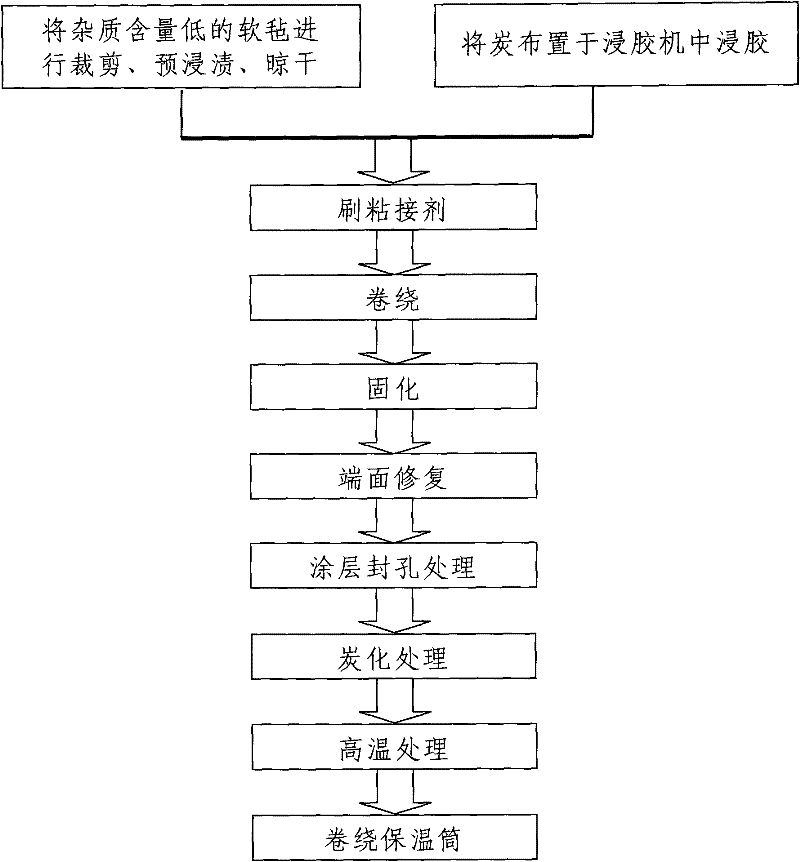

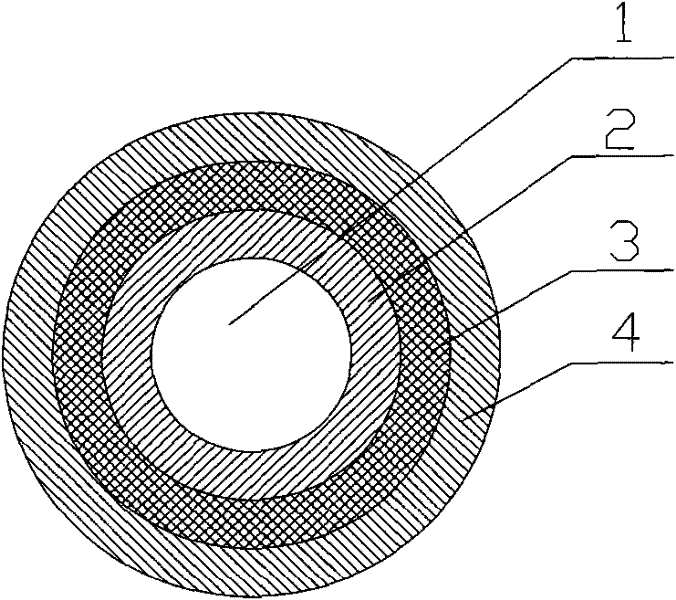

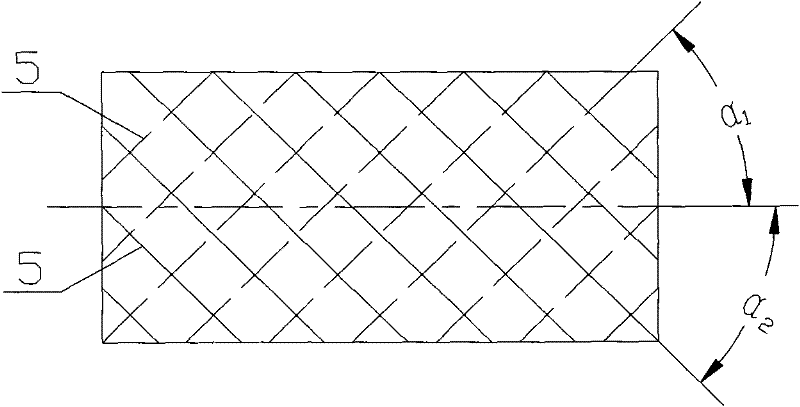

[0036] Step 1: Use polyacrylonitrile-based carbon felt with an ash content less than 2000ppm, cut the polyacrylonitrile-based carbon felt to a width of 30 mm, place it in a dipping machine, and pre-impregnate the polyacrylonitrile-based carbon felt with an impregnating agent. The impregnating agent is the mixed glue of alcohol or acetone and phenolic resin, the mass fraction of phenolic resin in the mixed glue is 20%, wherein the phenolic resin is aminophenolic resin, boron phenolic resin, barium phenolic resin or water-soluble phenolic resin The amount of resin and impregnating agent is to submerge the soft felt, and then dry the pre-impregnated soft felt for 5 hours;

[0037] Step 2, the twill carbon of 1K is arranged in the dipping machine (wherein K refers to the number of thousands of tows), and the carbon cloth is dipped with the dipping solution, and the dipping solution is a mixture of alcohol or acetone and phenolic resin Mix the glue solution, the mass fraction of ph...

Embodiment 2

[0046] Step 1, using polyacrylonitrile graphite felt with an ash content less than 1000ppm, cutting the polyacrylonitrile graphite felt to a width of 120 mm and placing it in a dipping machine, pre-impregnating the polyacrylonitrile graphite felt with an impregnating agent, the impregnating agent It is a mixed glue of alcohol or acetone and phenolic resin, the mass fraction of phenolic resin in the mixed glue is 50%, wherein the phenolic resin is aminophenolic resin, boron phenolic resin, barium phenolic resin or water-soluble phenolic resin, impregnated The amount of agent used is to submerge the soft felt, and then dry the pre-impregnated soft felt for 60 hours;

[0047] Step 2, arrange the plain carbon of 1K in the dipping machine (wherein K refers to the number of thousands of tows), and dip the carbon cloth with the dipping solution, which is a mixture of alcohol or acetone and phenolic resin Mix glue solution, the mass fraction of phenolic resin in the dipping solution i...

Embodiment 3

[0056] Step 1, using viscose-based graphite felt with an ash content less than 1000ppm, cutting the viscose-based graphite felt to a width of 110 mm and placing it in a dipping machine, pre-impregnating the viscose-based graphite felt with an impregnating agent, the impregnating agent It is a mixed glue solution of alcohol or acetone and furfurone resin, the mass fraction of furfurone resin in the mixed glue solution is 80%, the amount of impregnating agent is enough to submerge the soft felt, and then dry the pre-impregnated soft felt for 32 hours;

[0057] Step 2, arrange the plain carbon of 12K in the dipping machine (wherein K refers to the number of thousands of tows), and dip the carbon cloth with the dipping solution, which is a mixture of alcohol or acetone and phenolic resin Mix the glue solution, the mass fraction of phenolic resin in the dipping solution is 80%, wherein the phenolic resin is aminophenolic resin, boron phenolic resin, barium phenolic resin or water-so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com