Track on-line monitoring method and track on-line monitoring system

A technology for track and monitoring data, which is used in railway vehicle shape measuring instruments, railway car body parts, railway auxiliary equipment, etc. volume and cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

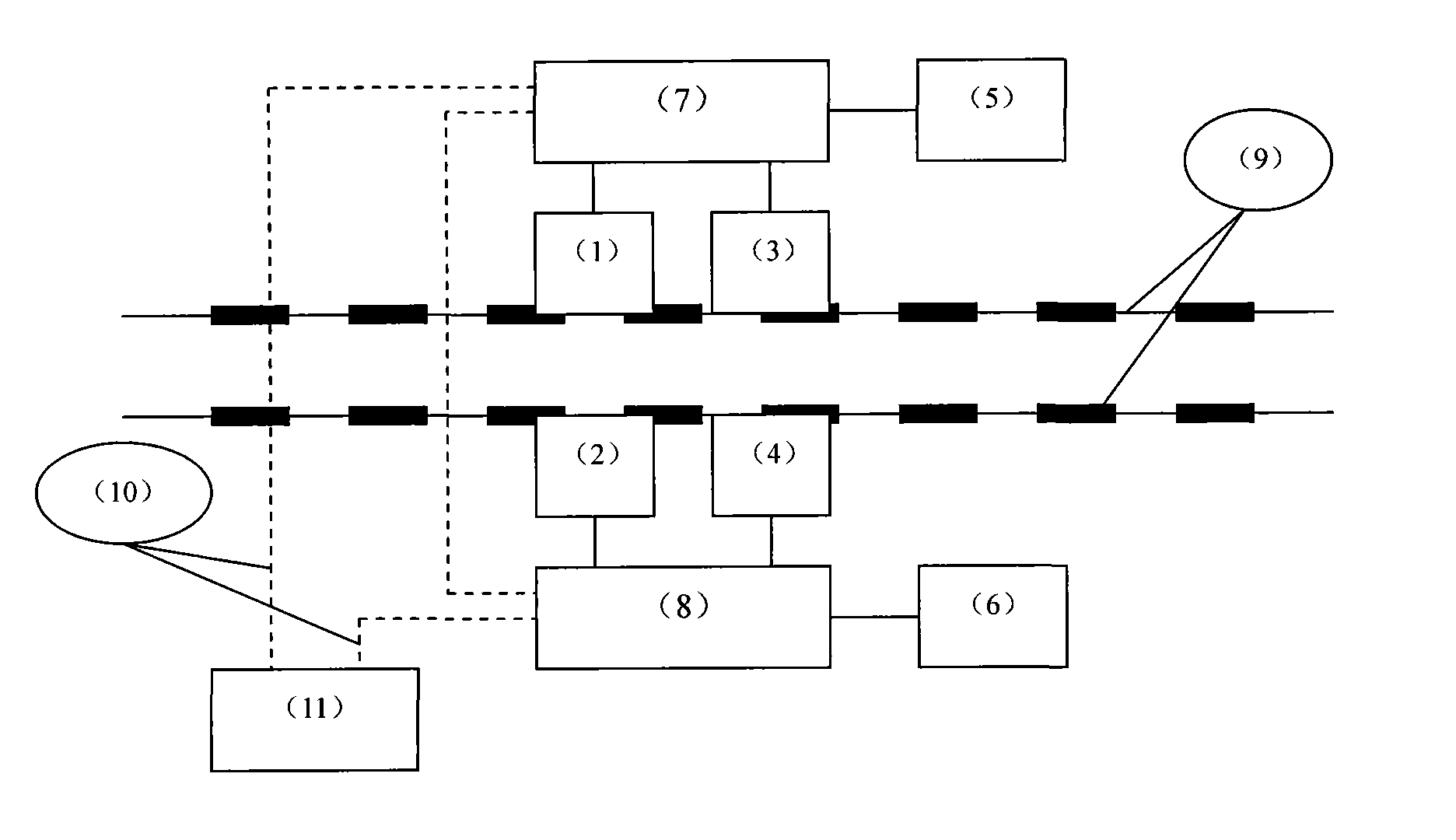

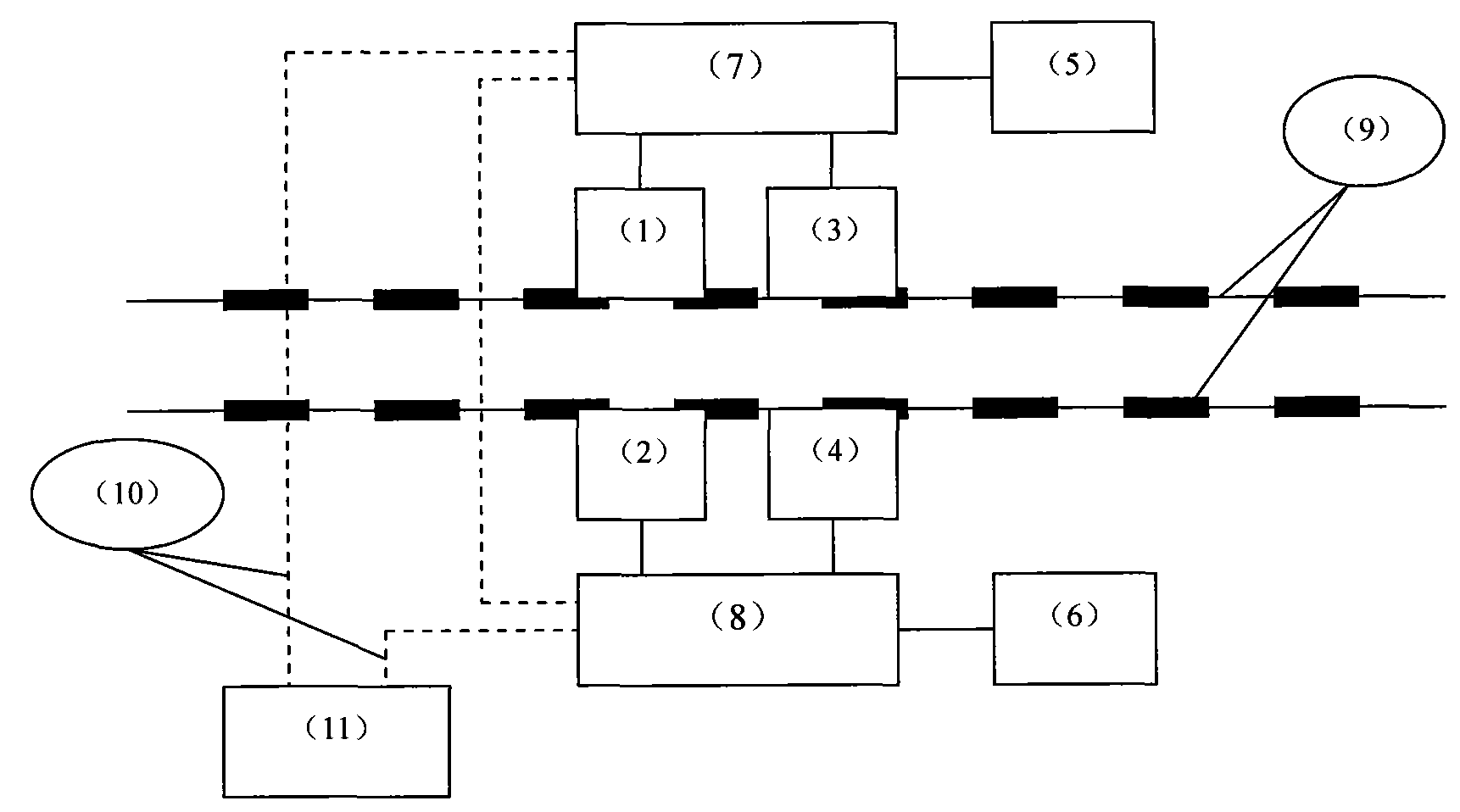

[0010] The embodiments of the present invention are described below by taking the drawings as an example.

[0011] figure 1 Shows the composition diagram of the track online monitoring system of an embodiment of the present invention, including the composition diagram of the track online monitoring system at a track test point, in which:

[0012] (1) and (2) are displacement sensors, and ordinary displacement sensors can be used; (3) and (4) are vibration sensors, and the working vibration spectrum can be used to effectively adapt to the track vibration spectrum; the displacement sensor and vibration sensor are set in (5) and (6) are laser distance detectors, which can be used to measure the tiny variables of the track. The laser distance detectors are set on both sides of the track. The height is based on the laser beam scanning to the outer edge of the track, and a combination of multiple laser distance detectors is used to scan and measure the distance to the outer edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com