Method for transforming crude argon column condenser with non-condensable gas discharging pipe, and crude argon column condenser

A crude argon column and discharge pipe technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve the problem of increasing equipment materials and processing and manufacturing costs, increasing the processing difficulty of crude argon column condensers, and non-condensable gas emissions. Pipes are prone to leakage and other problems, so as to achieve the effect of reducing material cost, reducing labor cost and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

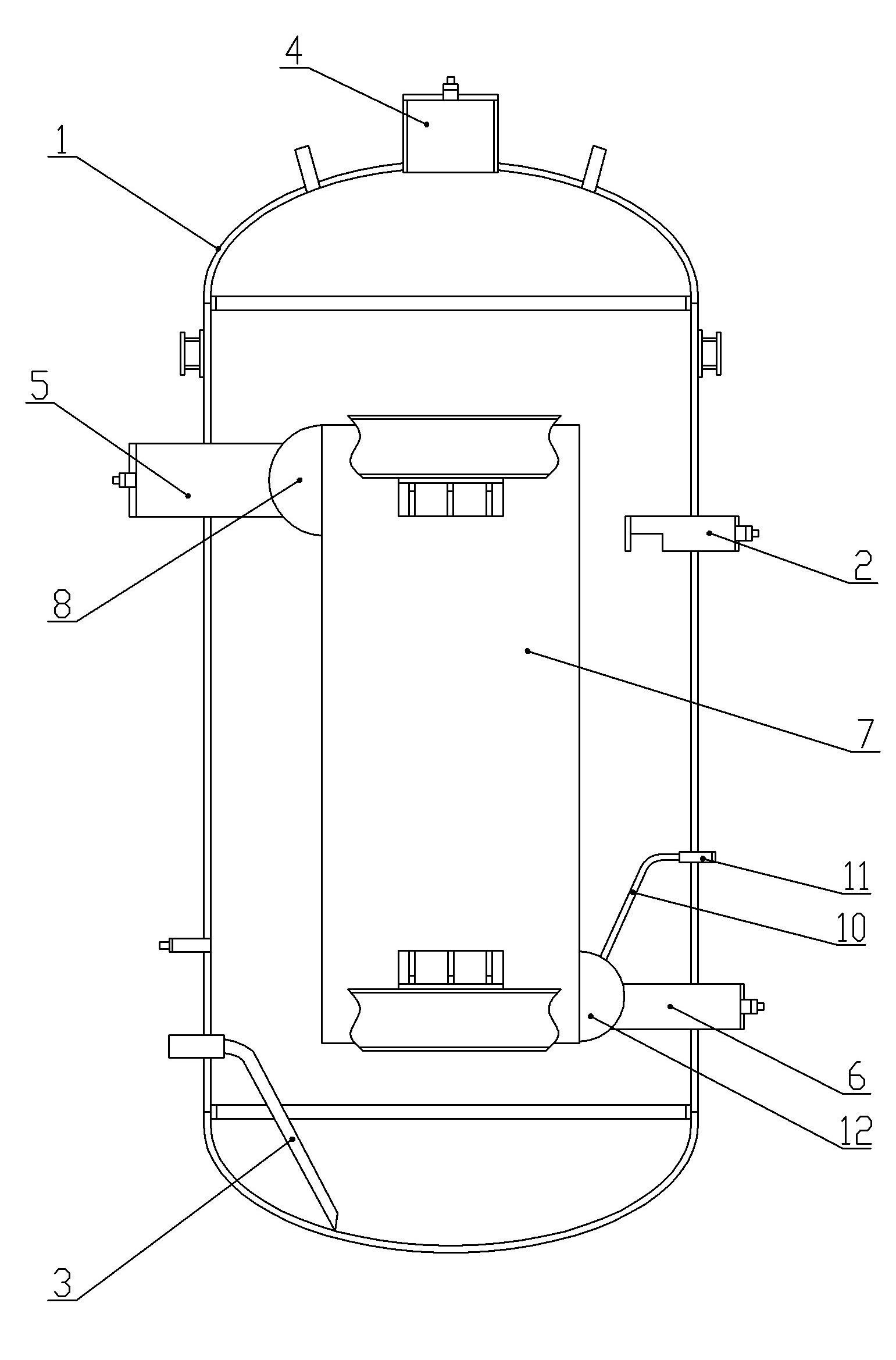

[0031] Embodiment 1: A modification method for a crude argon tower condenser with a non-condensable gas discharge pipe. The existing crude argon tower condenser with a non-condensable gas discharge pipe includes a closed tank and a plate installed in the tank Finned heat exchanger, the tank body is provided with liquid air inlet pipe, outlet pipe, liquid air steam outlet pipe, the plate bundle body, upper head, lower head, argon Gas inlet pipe and liquid argon outlet pipe; the upper head of the plate-fin heat exchanger is connected to the argon inlet pipe to pass through the tank, and the lower head of the plate-fin heat exchanger is connected to the liquid The argon outlet pipe passes through the tank body, the centerline of the liquid argon outlet pipe is lower than the centerline of the lower head, the upper part of the lower head is connected to the non-condensable gas discharge pipe, and passes through the tank body to the outside of the tank,

[0032] Firstly, remove the...

Embodiment 2

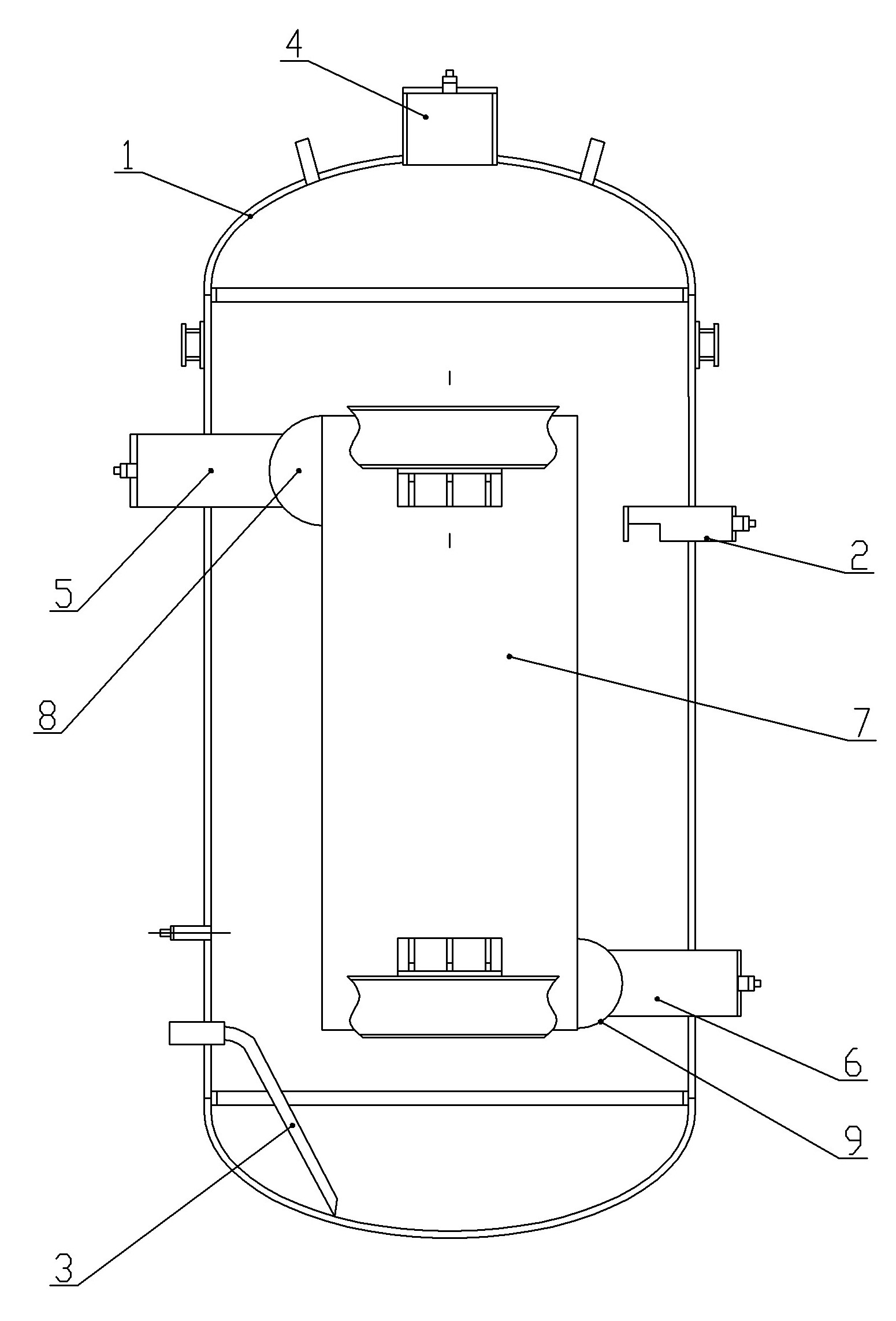

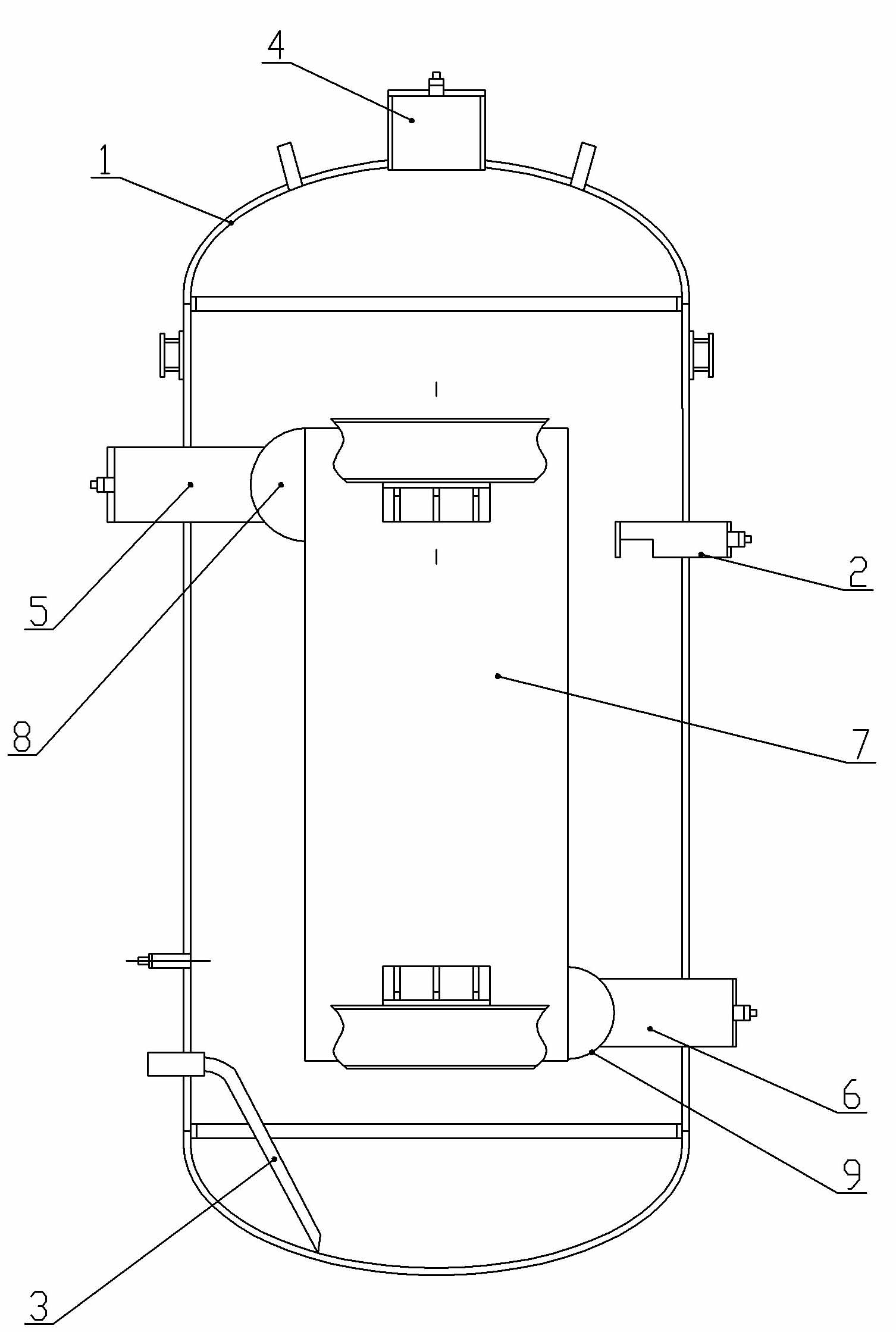

[0039] Embodiment two: see figure 2 , a crude argon tower condenser in the figure, including a closed tank body and a plate-fin heat exchanger installed in the tank body, the tank body is provided with liquid air inlet pipes, outlet pipes, and liquid air steam outlet pipes. tube, the plate bundle body, upper head, lower head, argon inlet pipe, and liquid argon outlet pipe contained in the plate-fin heat exchanger; the upper head of the plate-fin heat exchanger is connected to the argon The gas inlet pipe passes through the tank, and the lower head of the plate-fin heat exchanger is connected with a liquid argon outlet pipe to pass through the tank, and the centerline of the liquid argon outlet pipe coincides with the centerline of the head, The diameter of the liquid argon outlet pipe is 1.3-2.0 times the standard size designed according to the national or industry standards and combined with the production capacity requirements, and the value is preferably 1.5 times.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com