Epoxy resin mortar and preparation method thereof

A technology of epoxy resin and mortar, which is applied in the field of high-insulation epoxy resin mortar and its preparation, and can solve problems such as waste, failure to meet normal operation time, and inability to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

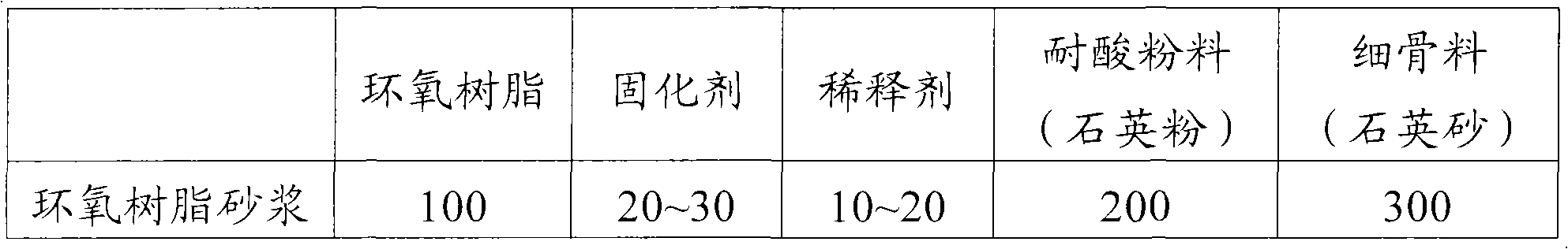

Image

Examples

example 1

[0026] Example 1: First, by weight, weigh 90 parts of epoxy resin, 23 parts of curing agent, 27 parts of diluent, 180 parts of acid-resistant powder and 320 parts of aggregate; secondly, dilute the epoxy resin with diluent; again, Add acid-resistant powder and aggregate to the diluted epoxy resin and mix; finally, add curing agent and mix to form epoxy resin mortar.

example 2

[0027] Example 2: Except for using 25 parts of curing agent, 26 parts of diluent, 190 parts of acid-resistant powder and 310 parts of aggregate, epoxy resin mortar was prepared using the method basically the same as that of Example 1.

example 3

[0028] Example 3: Except for using 24 parts of curing agent, 28 parts of diluent, 170 parts of acid-resistant powder and 325 parts of aggregate, epoxy resin mortar was prepared using the method basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com