Glass ionomer cement compound used for dental department

A composite and glass technology, applied in dentistry, dental prosthesis, dental preparations, etc., can solve the problems of insufficient mechanical strength and poor durability of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

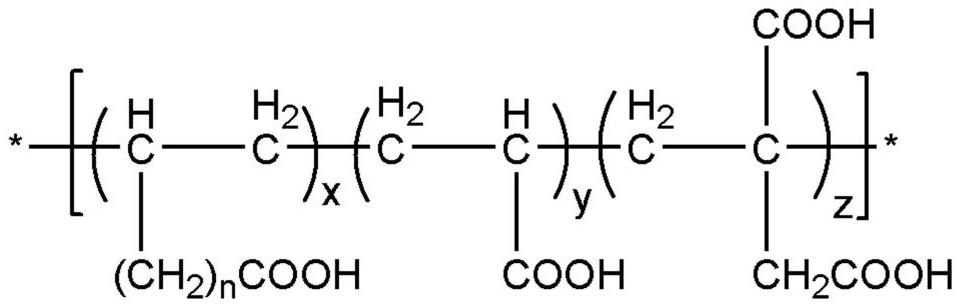

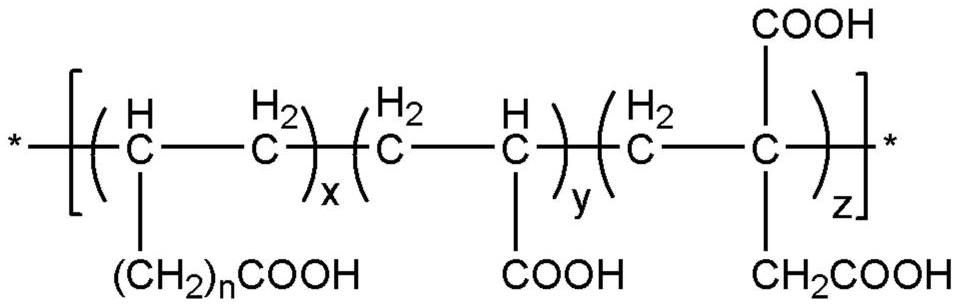

[0025] Synthesis of tricarboxylic acid copolymers of acrylic acid, itaconic acid and 4-pentenoic acid and preparation of glass ionomer cements.

[0026] Get 19.95g acrylic acid monomer, 8.55g itaconic acid monomer, 1.5g 4-pentenoic acid monomer and dissolve in 140g deionized water; Get 1.80g potassium persulfate and dissolve in 40g deionized water, be mixed with initiator aqueous solution, Take half of the aqueous initiator solution and place it in a four-necked flask, and preheat it at 80°C for half an hour. The remaining initiator aqueous solution and monomer aqueous solution were respectively filled in different constant pressure dropping funnels, and were added dropwise to the flask at a constant speed for 2 hours; after the dropwise addition, the reaction system was reacted at 80°C for 16 hours , and then purify the product. Dissolve the synthesized polycarboxylate solid in deionized water of equal mass to prepare 50 wt% polycarboxylate solution A.

[0027] According to...

Embodiment 2

[0030] Synthesis of tricarboxylic acid copolymers of acrylic acid, itaconic acid and 4-pentenoic acid and preparation of glass ionomer cement

[0031] Get 18.90g acrylic acid monomer, 8.10g itaconic acid monomer, 3.0g 4-pentenoic acid monomer and dissolve in 140g deionized water; Get 1.80g potassium persulfate and dissolve in 40g deionized water, be mixed with initiator aqueous solution, Take half of the aqueous initiator solution and place it in a four-necked flask, and preheat it at 80°C for half an hour. The remaining initiator aqueous solution and monomer aqueous solution were respectively filled in different constant pressure dropping funnels, and were added dropwise to the flask at a constant speed for 2 hours; after the dropwise addition, the reaction system was reacted at 80°C for 16 hours , and then purify the product. Dissolve the synthesized polycarboxylate solid in deionized water of equal mass to prepare 50 wt% polycarboxylate solution B.

[0032] According to t...

Embodiment 3

[0035] Get 17.85g acrylic acid monomer, 7.65g itaconic acid monomer, 4.5g 4-pentenoic acid monomer and dissolve in 140g deionized water; Get 1.80g potassium persulfate and dissolve in 40g deionized water, be mixed with initiator aqueous solution, Take half of the aqueous initiator solution and place it in a four-necked flask, and preheat it at 80°C for half an hour. The remaining initiator aqueous solution and monomer aqueous solution were respectively filled in different constant pressure dropping funnels, and were added dropwise to the flask at a constant speed for 2 hours; after the dropwise addition, the reaction system was reacted at 80°C for 16 hours , and then purify the product. Dissolve the synthesized polycarboxylate solid in deionized water of equal mass to prepare 50 wt% polycarboxylate solution C.

[0036] According to the mass ratio of powder to liquid 3.6:1, take the commercially available silica-alumina-fluorine glass powder and the above-mentioned polycarboxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com