Plant-growing permeable concrete, blending method and application thereof

A technology of permeable concrete and cement, which is applied in the direction of botany equipment and methods, applications, sustainable waste treatment, etc., can solve the problems that it is impossible to achieve vegetation greening environment, not suitable for building vegetation environment, lack of water permeability, etc., to solve the problem of heat island effect, reducing latent heat, and high water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

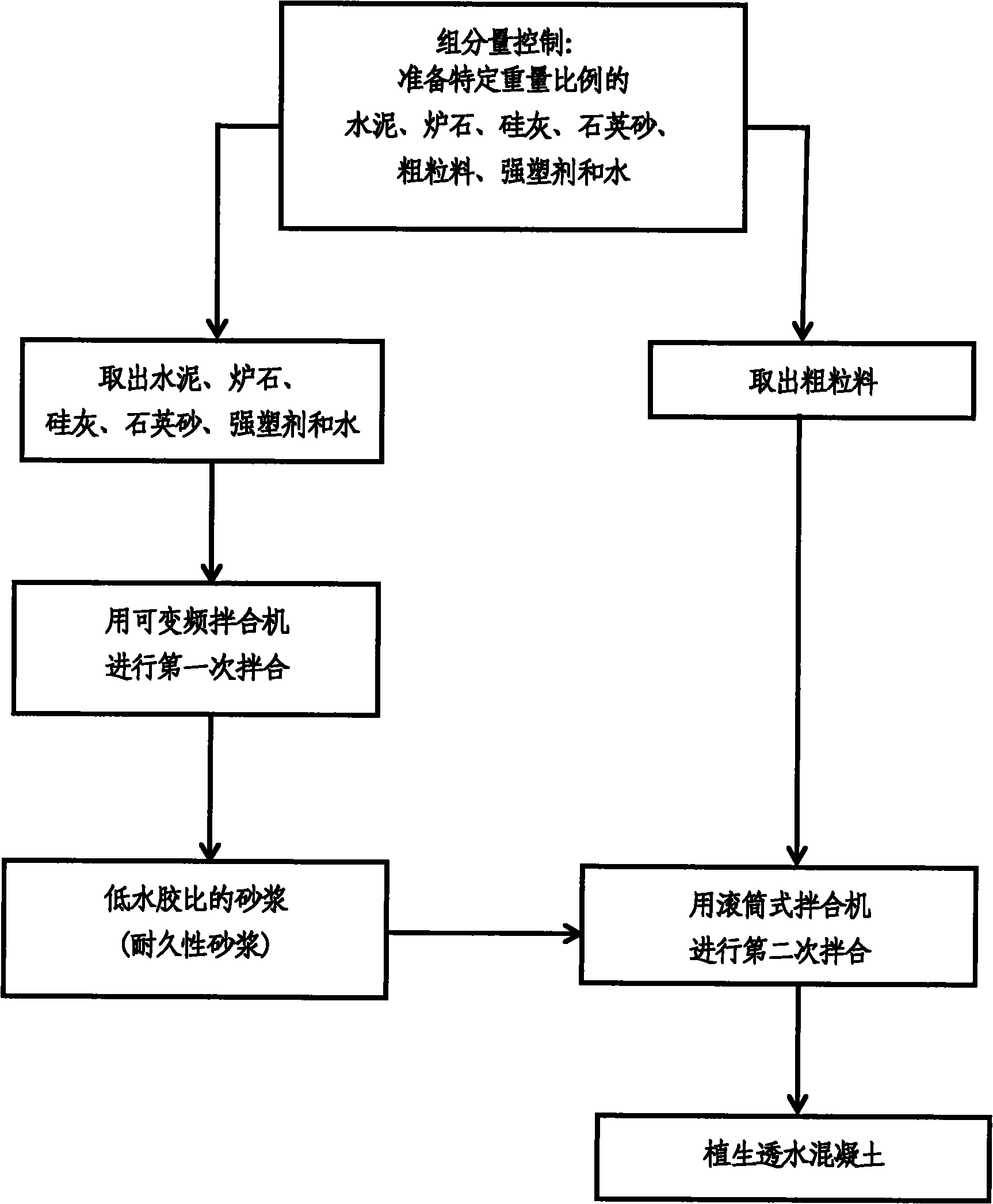

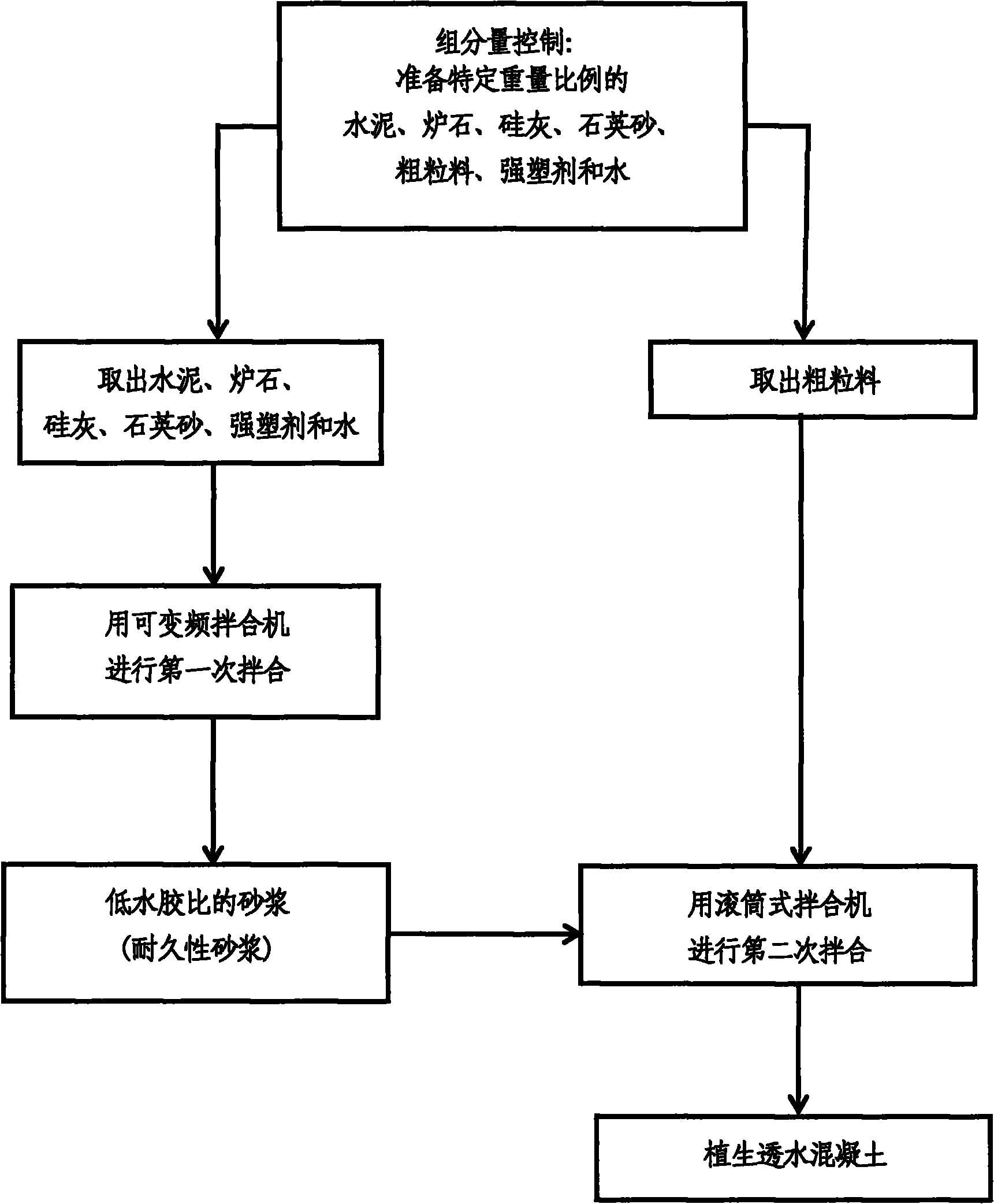

[0034] Such as figure 1 As shown, the weight ratio range of each component of plant-grown permeable concrete is as follows:

[0035] (1) Cement 1;

[0036] (2) Hearthstone 0.3-0.4;

[0037] (3) Silica fume 0.2-0.3;

[0038] (4) Quartz sand 1.5-2.0;

[0039] (5) coarse aggregate 10-13;

[0040] (6) superplasticizer 0.03-0.05;

[0041] (7) Water 0.23-0.3.

[0042] Mix the cement, furnace stone, silica fume, quartz sand, superplasticizer and water in the above ratio first, and perform the first mixing by a frequency-variable mixer (commonly known as a barrel mixer) to obtain a low-water Mortar with special rubber ratio (that is, high-concentration cement); then mix the mortar with the above-mentioned proportion of coarse aggregate (10-13), and carry out the second mixing by a drum mixer (commonly known as a gyro mixer). Mixing, the vegetable permeable concrete with high porosity and high compressive strength can be obtained.

Embodiment 2

[0044] When mixing and preparing plant-grown permeable concrete, the preferred weight ratio of each component is as follows:

[0045] Cement: furnace stone: silica fume: quartz sand: coarse aggregate: superplasticizer: water = 1: 0.33: 0.26: 1.8: 11: 0.04: 0.28.

[0046] The mixing steps are the same as in Example 1.

Embodiment 3

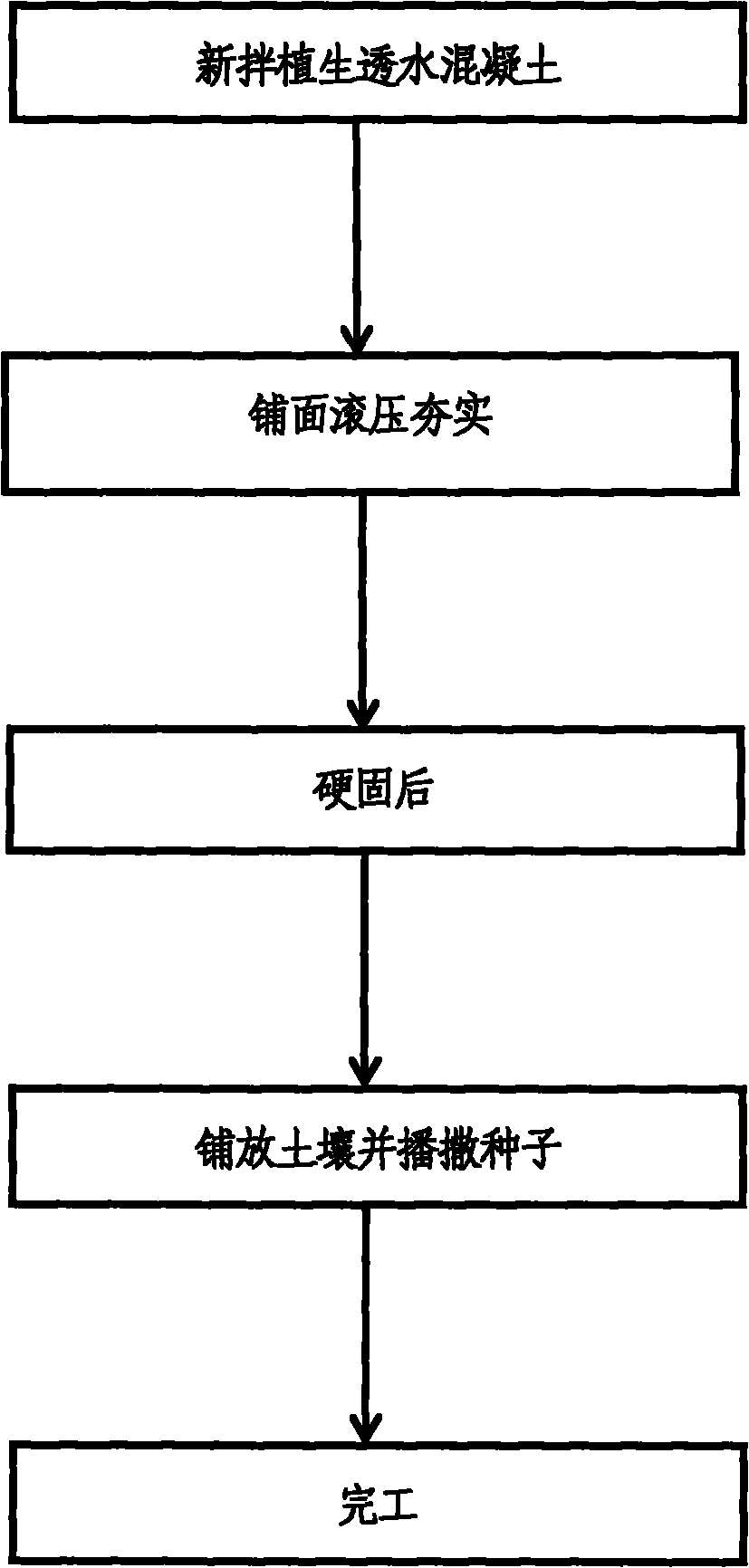

[0048] Such as figure 2 As shown, when the vegetation permeable concrete is paved, the pavement should be rolled and tamped first, and after it is hardened, the soil and seeds should be spread, so as to create an excellent vegetation environment and achieve the function of greening the environment. The vegetative permeable concrete has a high water permeability function, and can reduce the latent heat of the environment through the effect of vegetative growth and water permeability, effectively reduce the ambient temperature of cities or regions, and solve the heat island effect.

[0049] The plant-grown permeable concrete is also very suitable for green building materials, green buildings, base water retention, paved roads, park squares, sky gardens or general pedestrian walkways, roof rainwater recovery systems and hillsides, etc. as pavements for permeable layers.

[0050] The soil laid in this example is composed of clay and cultivation soil in a ratio of 1:1. But this r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com