Vibration data collection and fault analysis system of networking portable type steam turbine set

A steam turbine unit and vibration data technology, which is applied in the signal transmission system, machine/engine, engine start, etc., can solve problems such as single, poor processing efficiency, and weak system processing ability, so as to improve the overall performance of the system and reduce computing power. The effect of high pressure and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

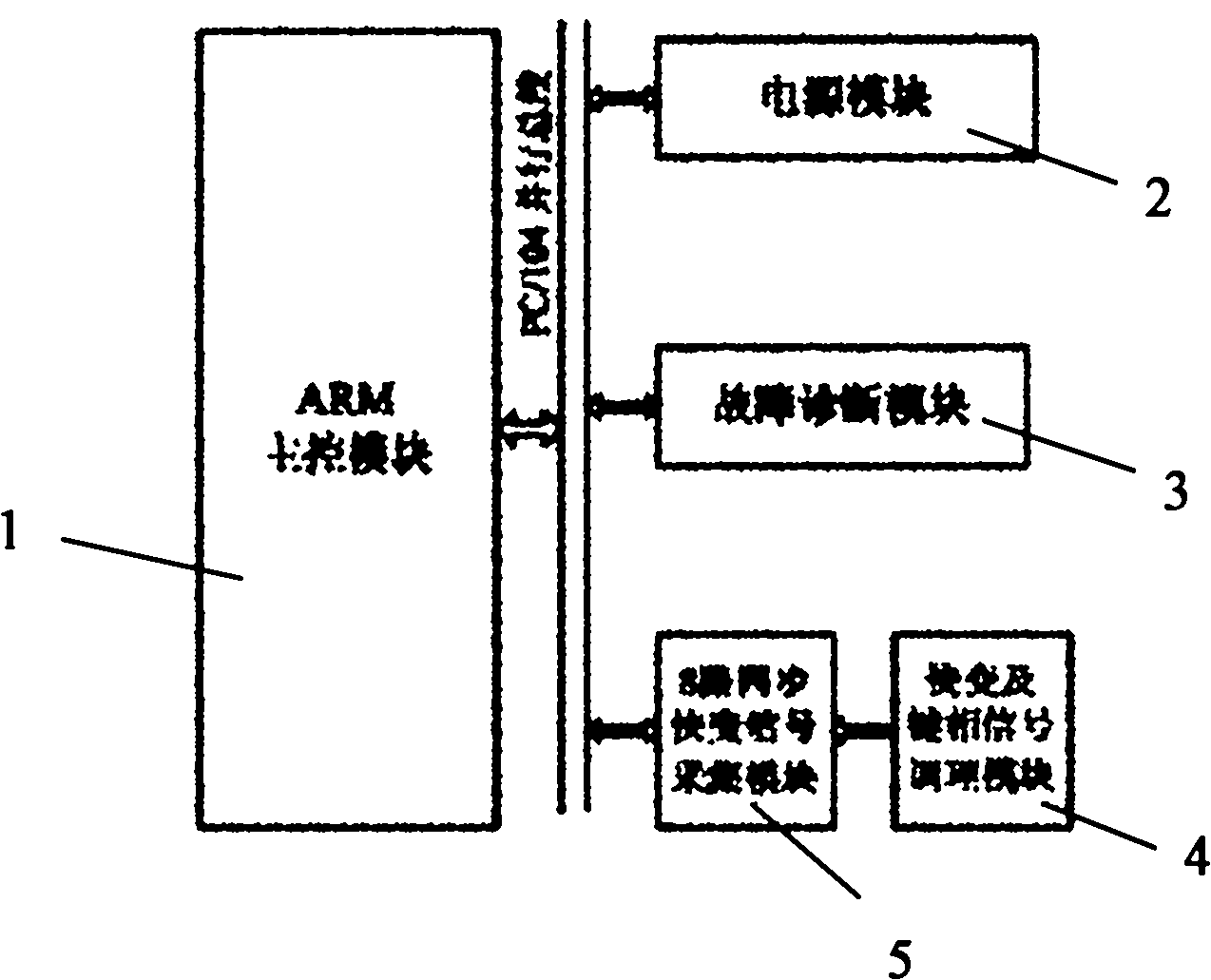

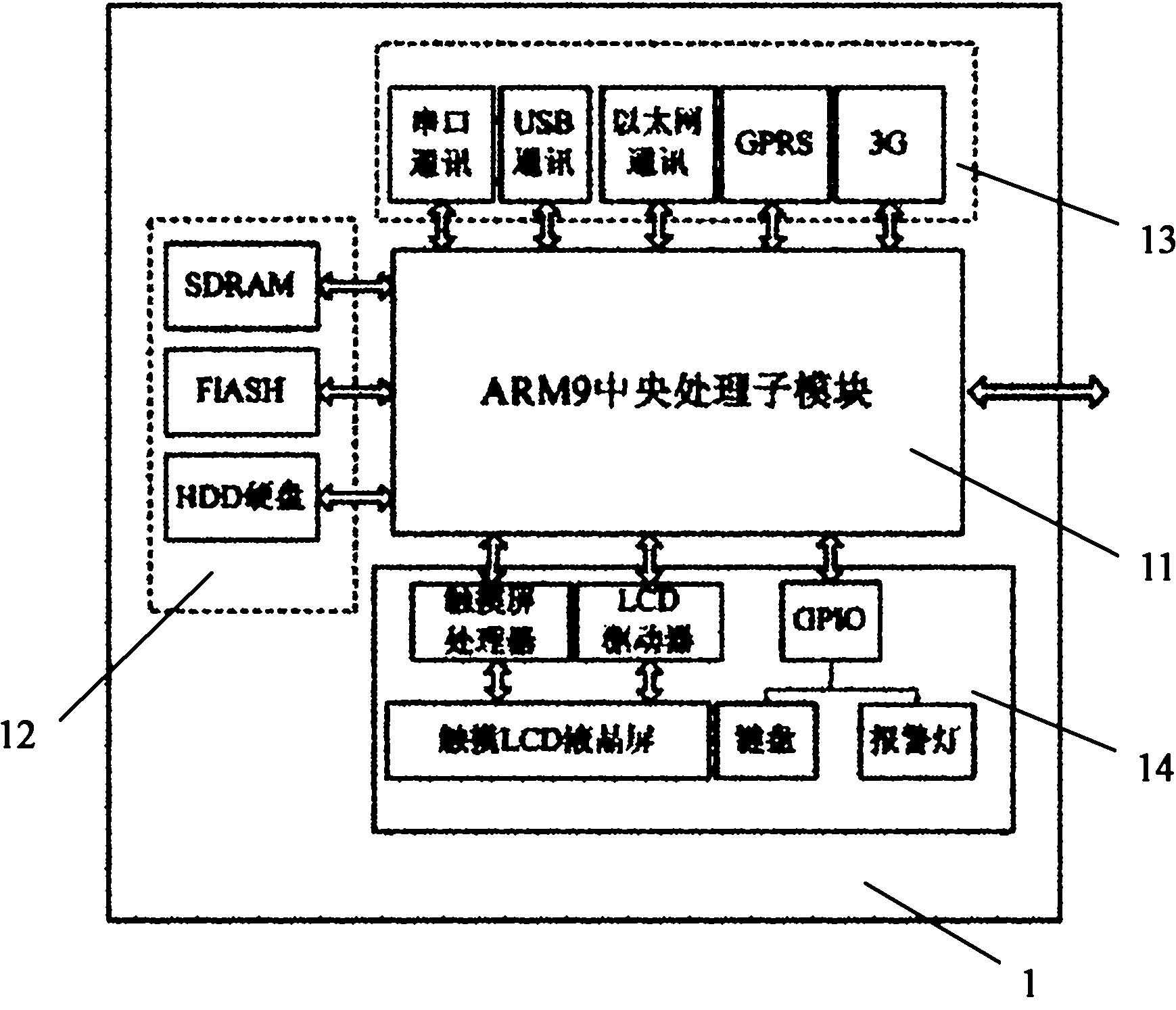

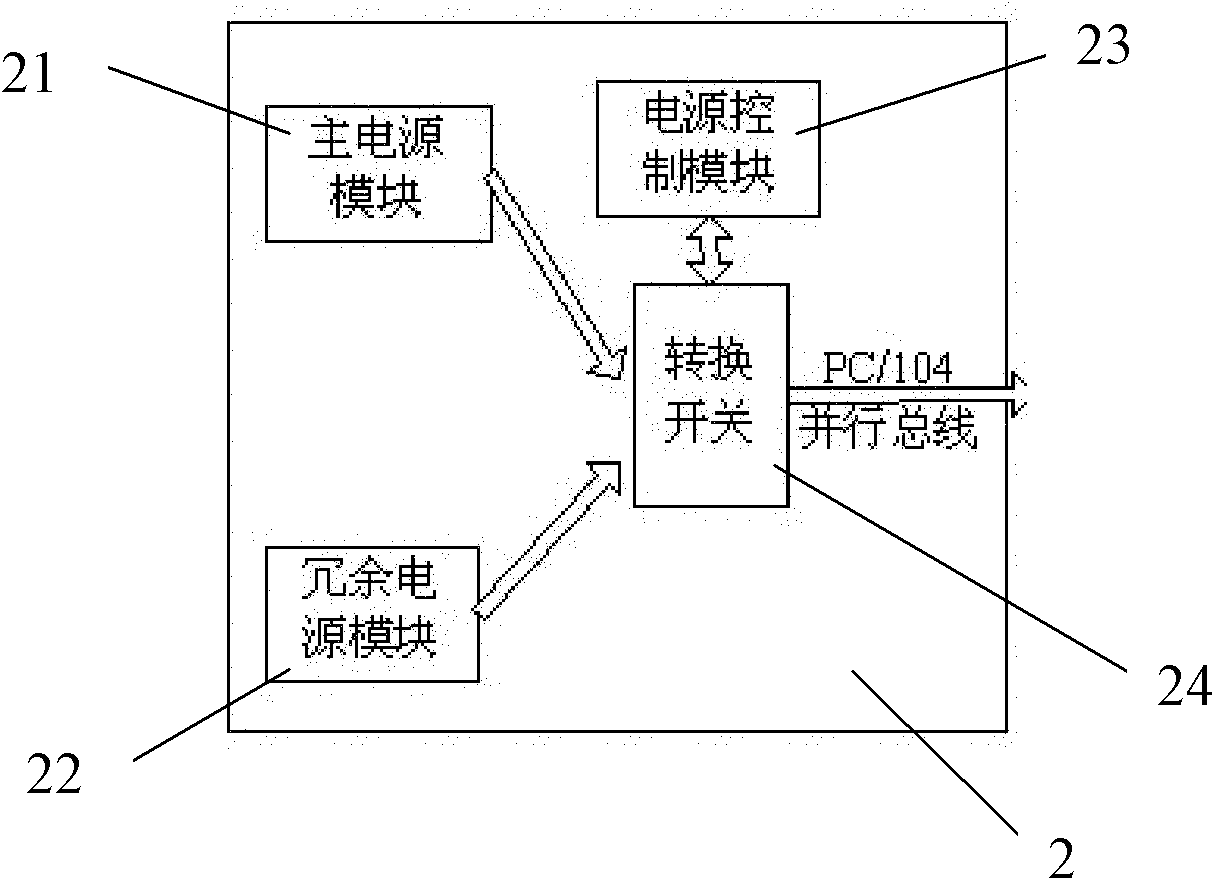

[0027] see figure 1 , a portable steam turbine vibration data acquisition and fault analysis system that can be networked. It consists of ARM main control module 1, power module 2, fault diagnosis module 3, and signal conditioning for preprocessing the fast-changing and key-phase signals transmitted by sensors. module 4, and 8 synchronous fast-changing signal acquisition modules 5 that can carry out key phase acquisition to synchronous fast-changing signals. Each module is designed based on the PC / 104 parallel bus standard. Change signal acquisition module 5, the output end of described synchronous fast change signal acquisition module 5 is connected with ARM main control module 1 by PC / 104 parallel bus communication, ARM main control module 1 is provided with to synchronous fast change signal acquisition module 5 Transfer data for storage, communication, analysis, diagnosis, and human-computer interaction system settings and status monitoring and analysis programs, as well as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com