Liquid flushing type multi-channel switching channel valve assembly

A multi-way switching and assembly technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of easy damage of electrical or pneumatic components, high cost of switching valves, high assembly requirements, etc., and achieve low cost and high use The effect of long life and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

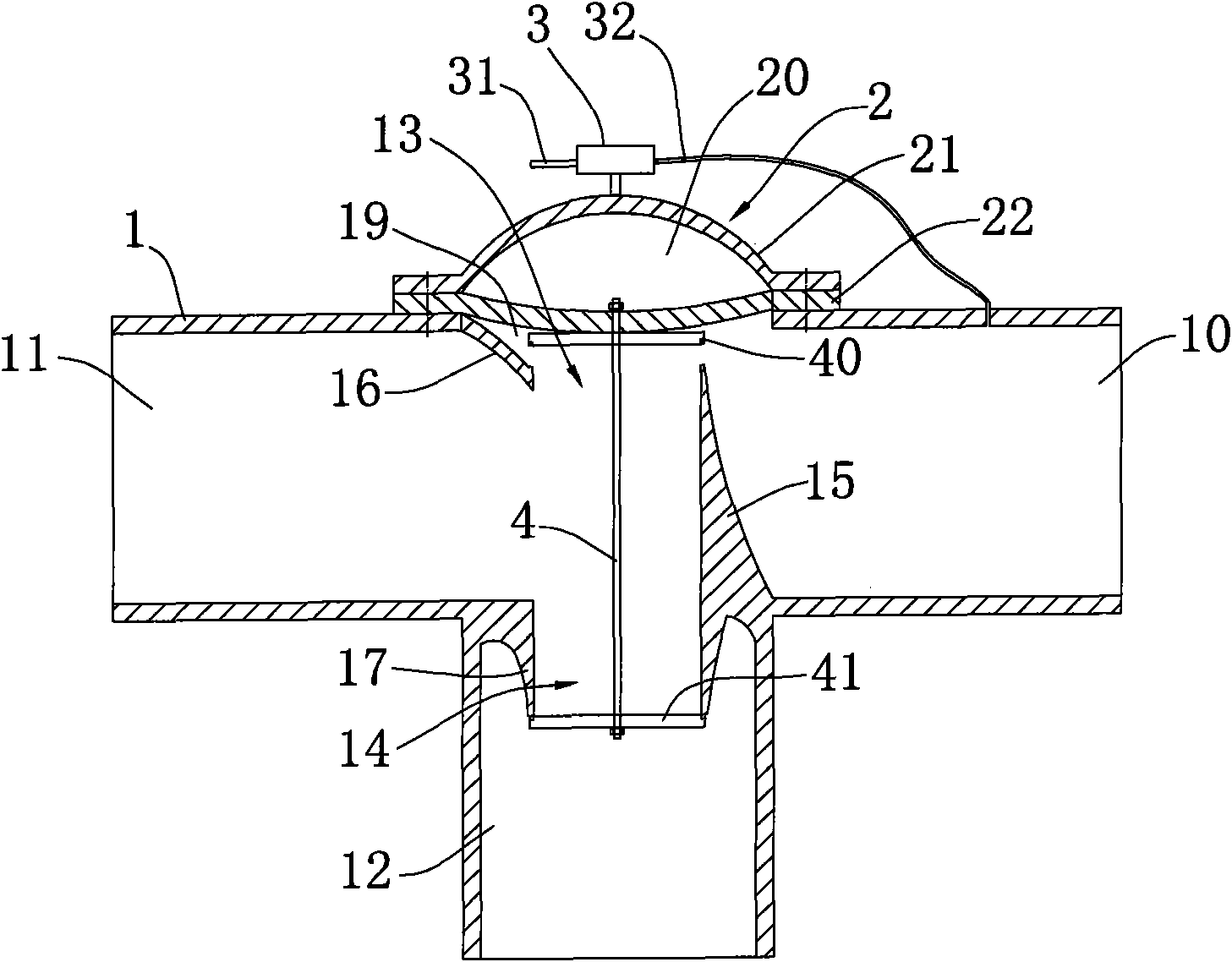

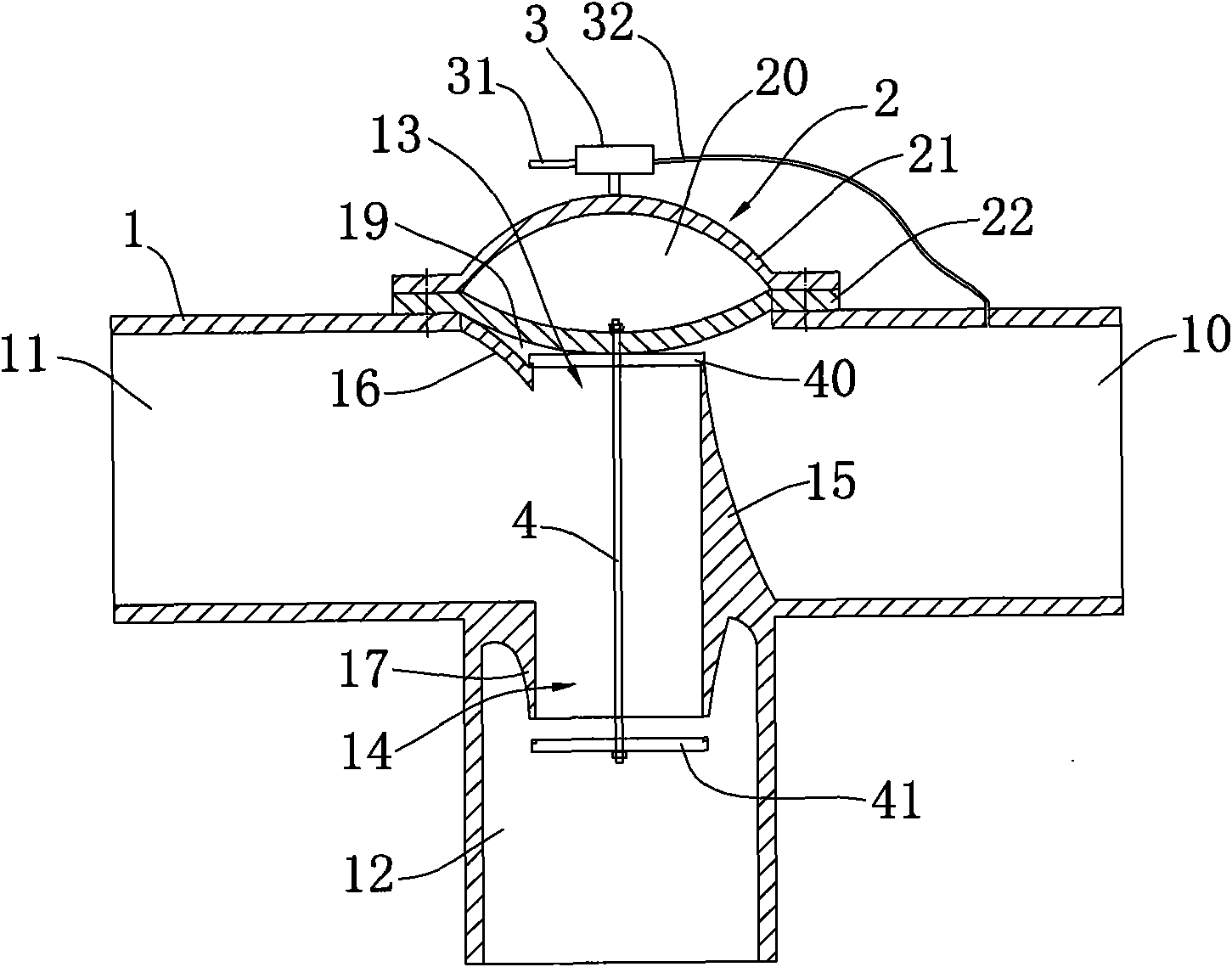

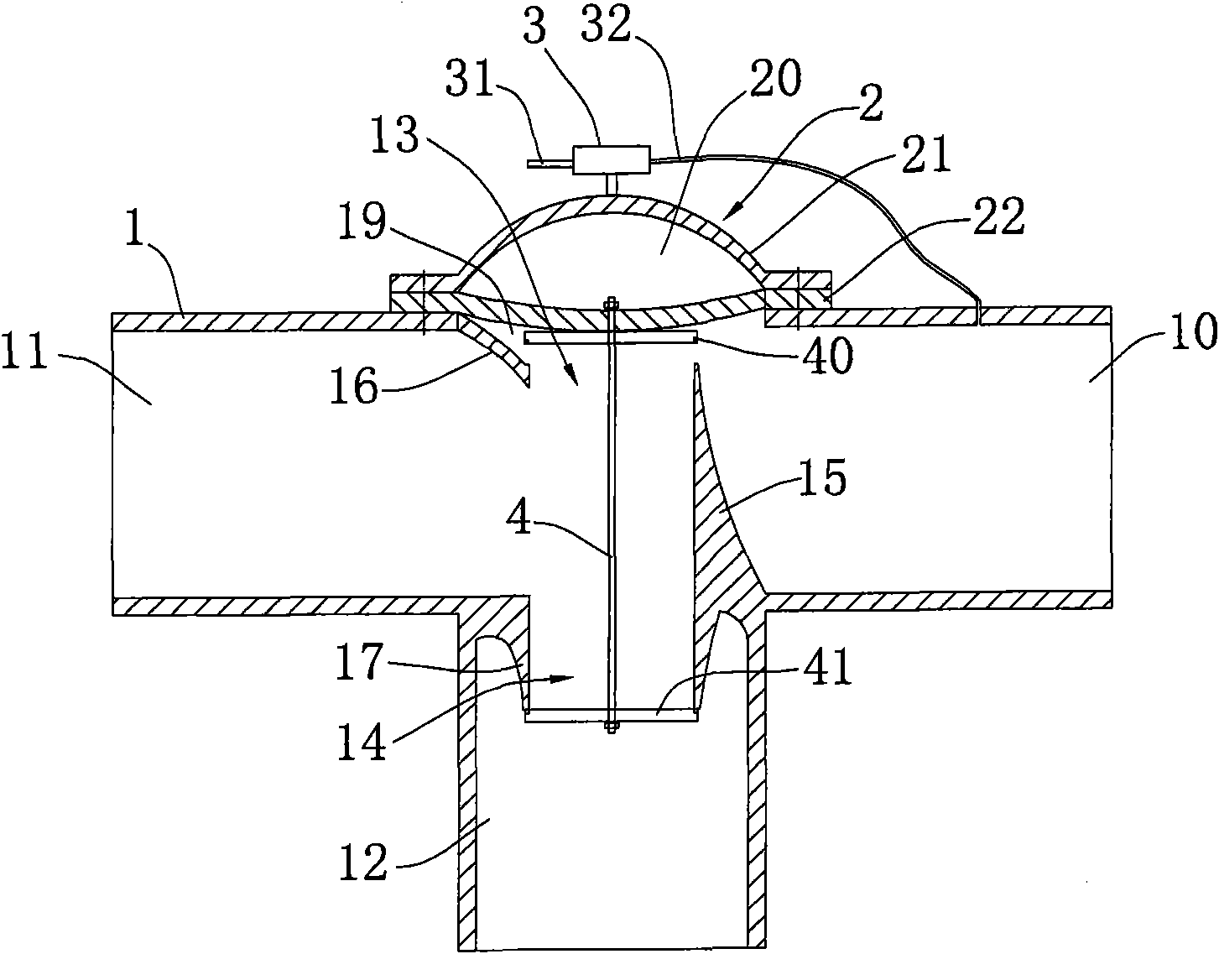

[0014] Such as figure 1 As shown, a liquid flushing type multi-way switching channel valve assembly includes a valve body 1, and the valve body 1 is provided with a water inlet chamber 10, a water outlet chamber 11 and a drainage chamber 12. The intersection of the three chambers 12 is provided with a diversion part I 13 connecting the water inlet chamber 10 and the water outlet chamber 11, a diversion part II 14 connecting the water outlet chamber 11 and the drainage chamber 12, and a control diversion part I 13, a diversion part II 14 Alternate on-off spool assembly, the valve body 1 is also provided with an elastic cavity 2 connected to the spool assembly and a pressure control mechanism for adjusting the internal pressure of the elastic cavity 2, the elastic cavity 2 The expansion and contraction movement generated by the adjustment of the pressure control mechanism is used to drive the valve core assembly to reciprocate and slide between the flow guide part I 13 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com