Vehicle high-pressure power steering rubber tube and preparation method thereof

A power steering and rubber hose technology, applied in chemical instruments and methods, hoses, pipes, etc., can solve the problems of soaring prices, shortage of CSM rubber, constraints, etc., and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

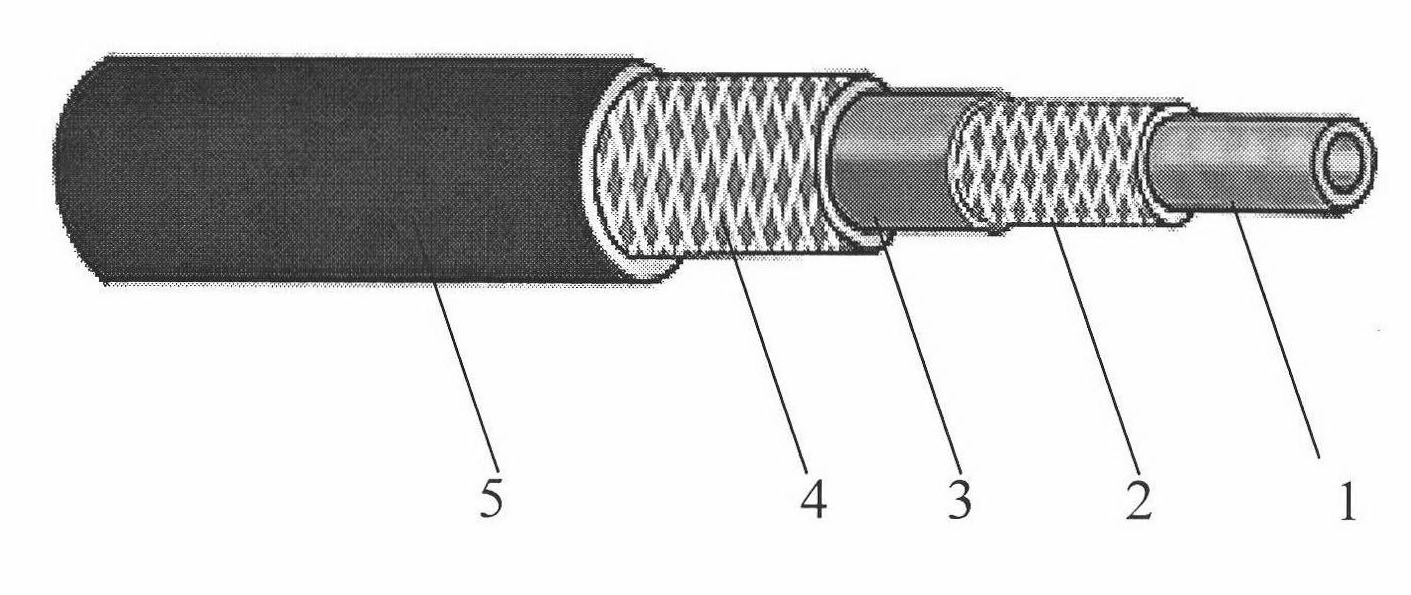

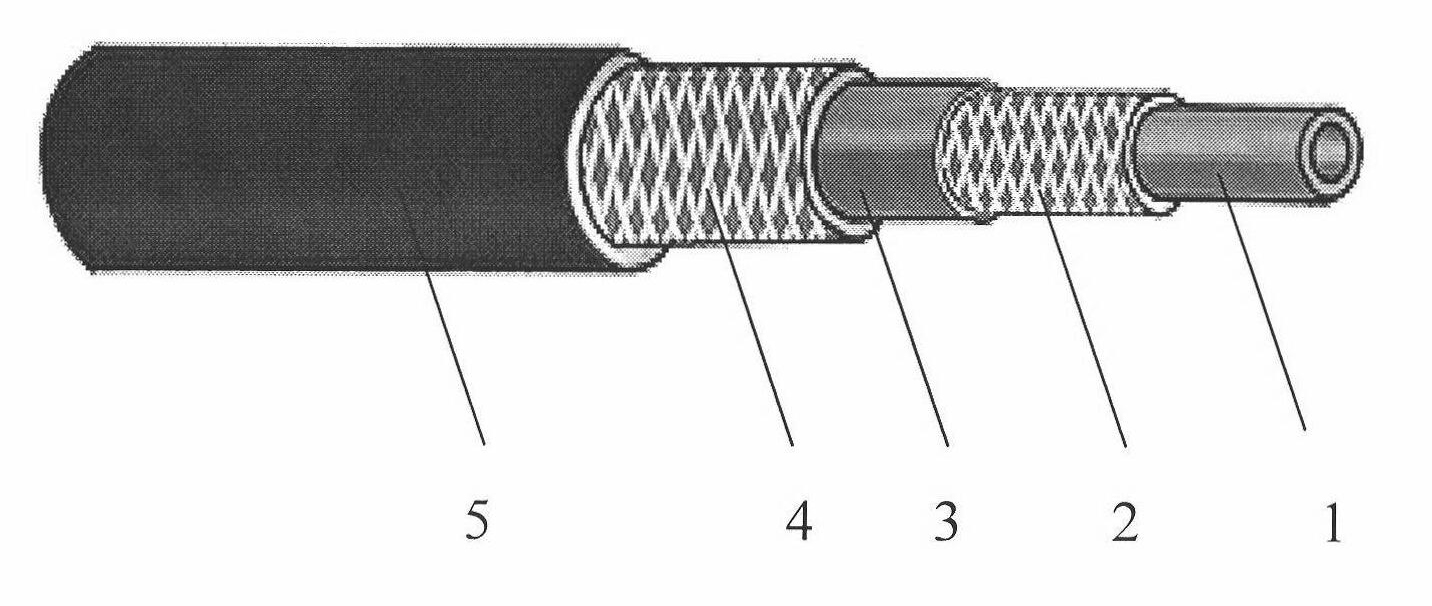

[0020] A five-layer circular power steering hose configured for automotive power steering is a power steering hose with ECO rubber as the inner layer for conveying media. From the inside to the outside: one layer is the inner layer of ECO rubber 1 , The second layer is a mesh nylon reinforcement layer 2, the third layer is an NBR film wrapped middle layer 3, the fourth layer is a mesh nylon reinforcement layer 4, and the fifth layer is an AEM rubber outer layer 5. The thickness is 2mm for the inner layer of ECO rubber, 0.5mm for the mesh nylon layer, 0.5mm for the middle layer of NBR, 0.5mm for the mesh nylon layer, 2mm for the outer layer of AEM, and the hole diameter of the inner layer of the hose is 9.8mm.

[0021] The specific production process is as follows:

[0022] 1) The extrusion temperature of the inner layer is: head 95°C, extrusion section 85°C, plasticizing section 85°C, feeding section 65°C, screw section 60°C, and the extrusion thickness is 4mm;

[0023] 2) Th...

Embodiment 2

[0033] Such as figure 1 As shown, it is a 5-layer circular power steering hose configured for automobile power steering gear. It is a power steering hose with ECO rubber as the inner layer for conveying medium. Layer 1 and the second layer are mesh nylon reinforcement layer 2, the third layer is NBR film wrapping middle layer 3, the fourth layer is mesh nylon reinforcement layer 4, and the fifth layer is AEM rubber outer layer 5. The thickness is 2mm for the inner layer of ECO, 0.5mm for the mesh nylon layer, 0.5mm for the middle layer of NER, 0.5mm for the mesh nylon layer, 2mm for the outer layer of AEM, and the aperture of the inner layer of the hose is 9.8mm.

[0034] Concrete production process is according to embodiment 1, difference is as follows:

[0035] 1) The extrusion temperature of the inner layer is: head 80°C, extrusion section 65°C, plasticizing section 65°C, feeding section 45°C, screw section 40°C, and the extrusion thickness is 2mm;

[0036] 2) The extrusi...

Embodiment 3

[0039] Such as figure 1 As shown, it is a five-layer circular power steering rubber hose configured for automobile power steering gear. It is a power steering hose with ECO as the inner layer for conveying medium. From the inside to the outside, it is as follows: one layer is ECO rubber The inner layer 1, the second layer is a mesh nylon reinforcement layer 2, the third layer is an NBR middle layer 3, the fourth layer is a mesh nylon reinforcement layer 4, and the fifth layer is an AEM rubber outer layer 5. The thickness is 2mm for the inner layer of ECO, 0.5mm for the mesh nylon layer, 0.5mm for the middle layer of NBR, 0.5mm for the mesh nylon layer, 2mm for the outer layer of AEM rubber, and the hole diameter of the inner layer of the hose is 9.8mm.

[0040] Concrete production process is according to embodiment 1, difference is as follows:

[0041] 1) The extrusion temperature of the inner layer is: head 90°C, extrusion section 80°C, plasticizing section 80°C, feeding sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com