Wafer type LED artistic light-emitting assembly and decorative lamps using same

A technology of light-emitting components and lighting, applied in the direction of light source, electric light source, point light source, etc., to achieve the effect of beautifying life, colorful lighting effects, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

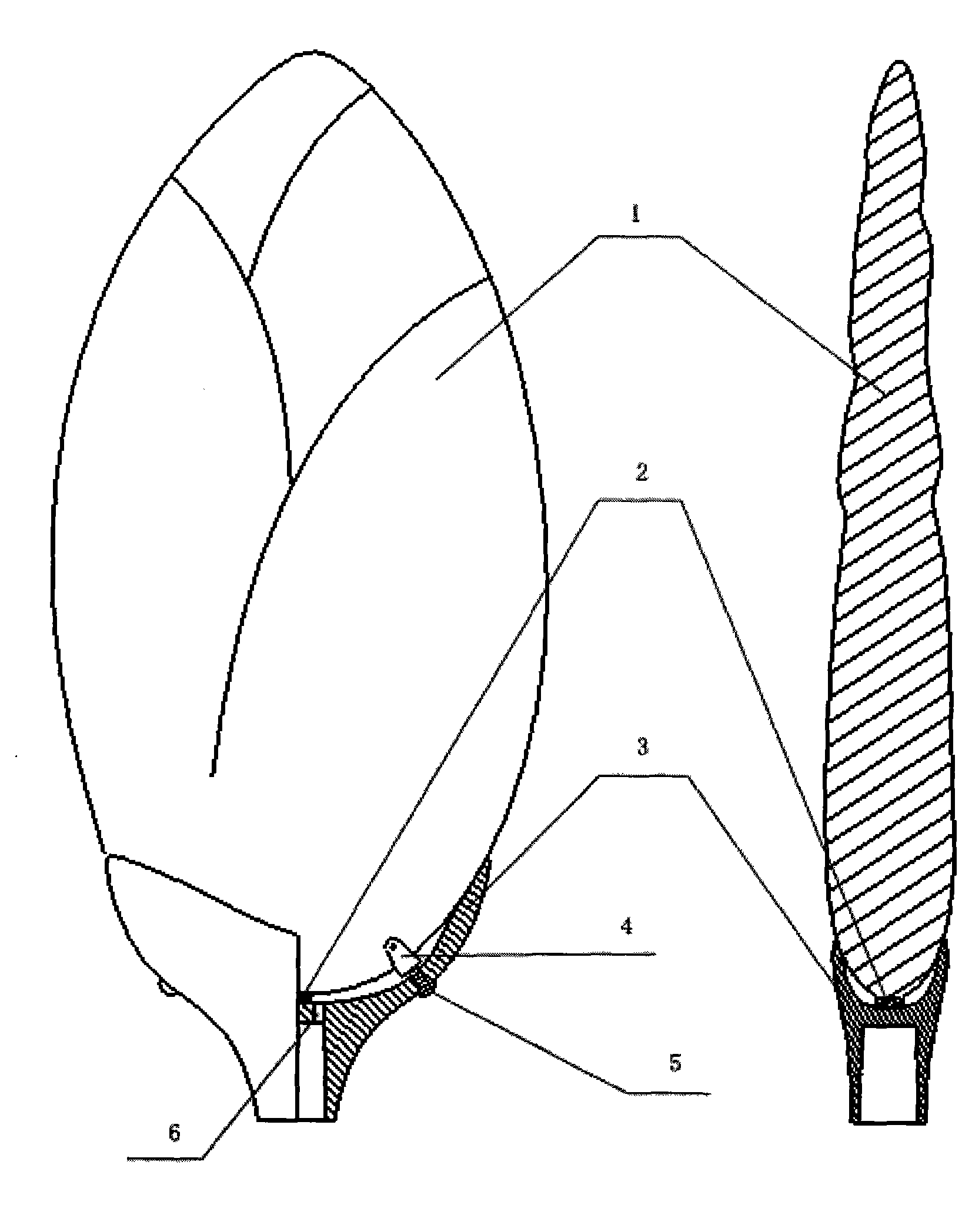

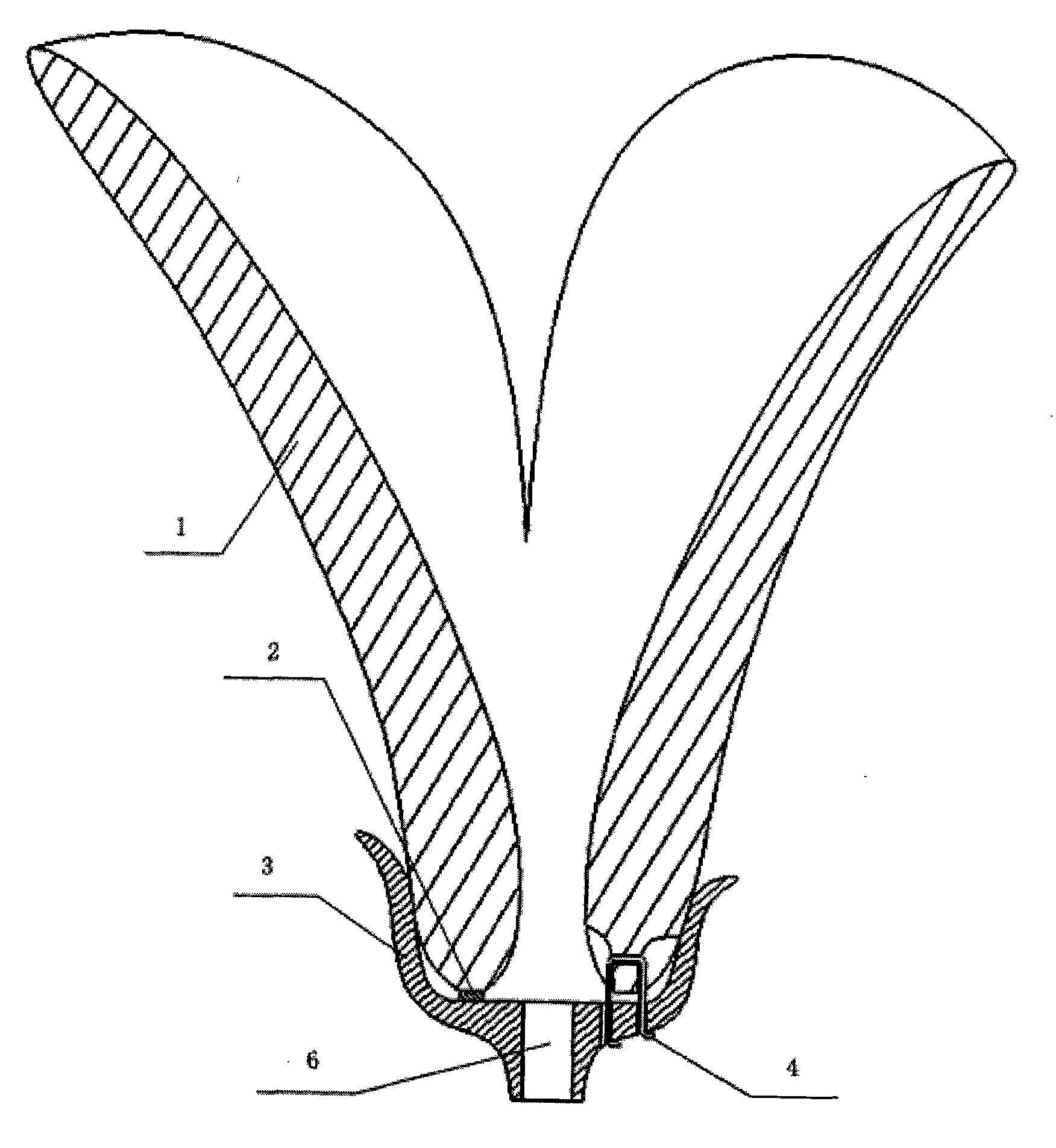

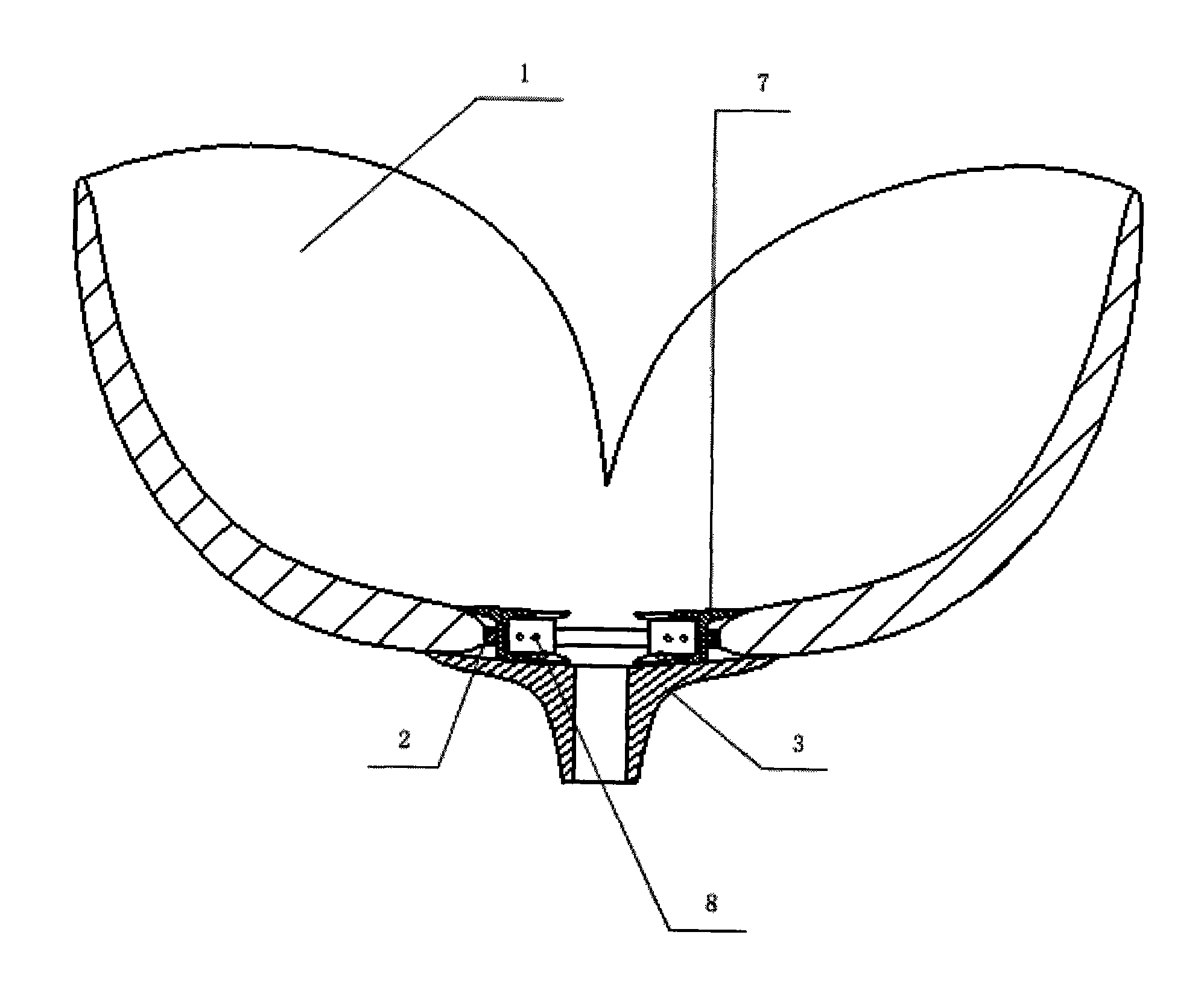

[0023] figure 1 One side edge of the middle light-emitting sheet 1 is wrapped by the heat sink 3 , and the edge of the heat sink 3 is closely attached to the light-emitting sheet 1 . After passing the edge of the heat sink 3 attached to the light-emitting sheet 1, the heat sink 3 and the light-emitting sheet 1 are no longer in contact, and a space for placing the LED2 and its connecting wires and the fastening device 4 is formed between the two . The connection wire of LED2 passes through the hole 6 and the decorative tube connected with the heat sink 3, and is connected with the circuit inside the lighting fixture. The fastening device 4 passes through the hole on the light-emitting sheet, and the end surface of the edge of the light-emitting sheet 1 is pressed against the light-emitting surface of the LED2 through the tension of the two screws 5 on both sides. on the inner surface. The light-emitting sheet 1 gradually bends to the side from the end surface, forming a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com