Improved lithium bromide air conditioning evaporator

An evaporator and lithium bromide technology, applied in the field of lithium bromide air conditioners, can solve problems such as lowering the outlet temperature of chilled water, reducing heat exchange efficiency, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

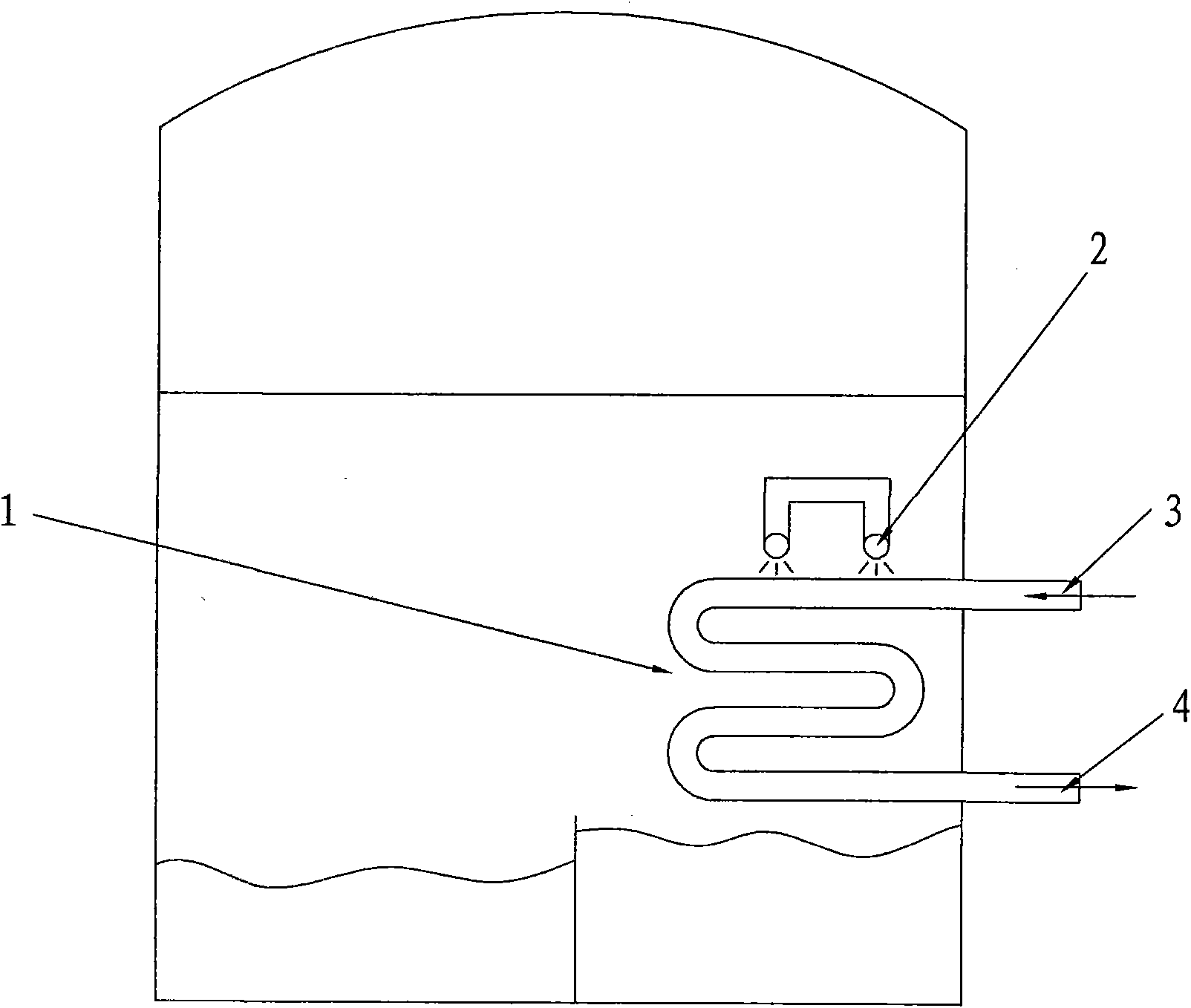

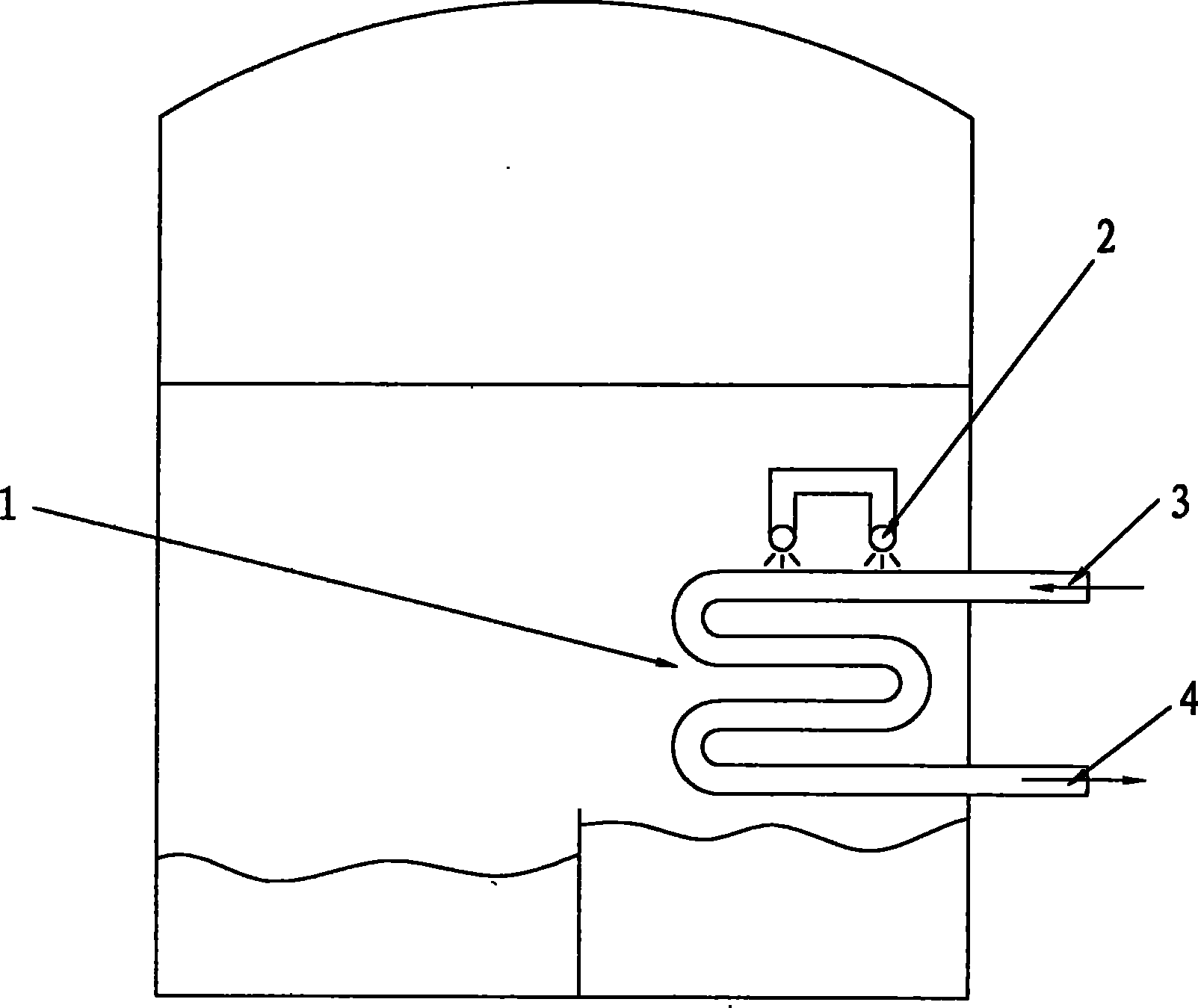

[0008] Such as figure 1 As shown, an improved lithium bromide air conditioner evaporator is composed of a refrigerant nozzle 2 and a heat exchanger 1; the refrigerant nozzle 2 is arranged above the heat exchanger 1 and cooperates with the heat exchange tube of the heat exchanger 1; The port of the heat exchange tube at the top of the heat exchanger 1 is the cold water inlet 3 , and the port of the heat exchange tube at the bottom of the heat exchanger 1 is the cold water outlet 4 .

[0009] What has been described above are only preferred embodiments of the present invention. It should be noted that, for those skilled in the art, some improvements and modifications can be made without departing from the principle of the present invention, which are also regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com