Dying control method of biomass materials

A drying control and biomass technology, which is applied in the field of biomass material drying control, can solve the problems of high energy consumption and low drying efficiency, so as to improve drying efficiency, increase humidity stability, avoid less drying and overbaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

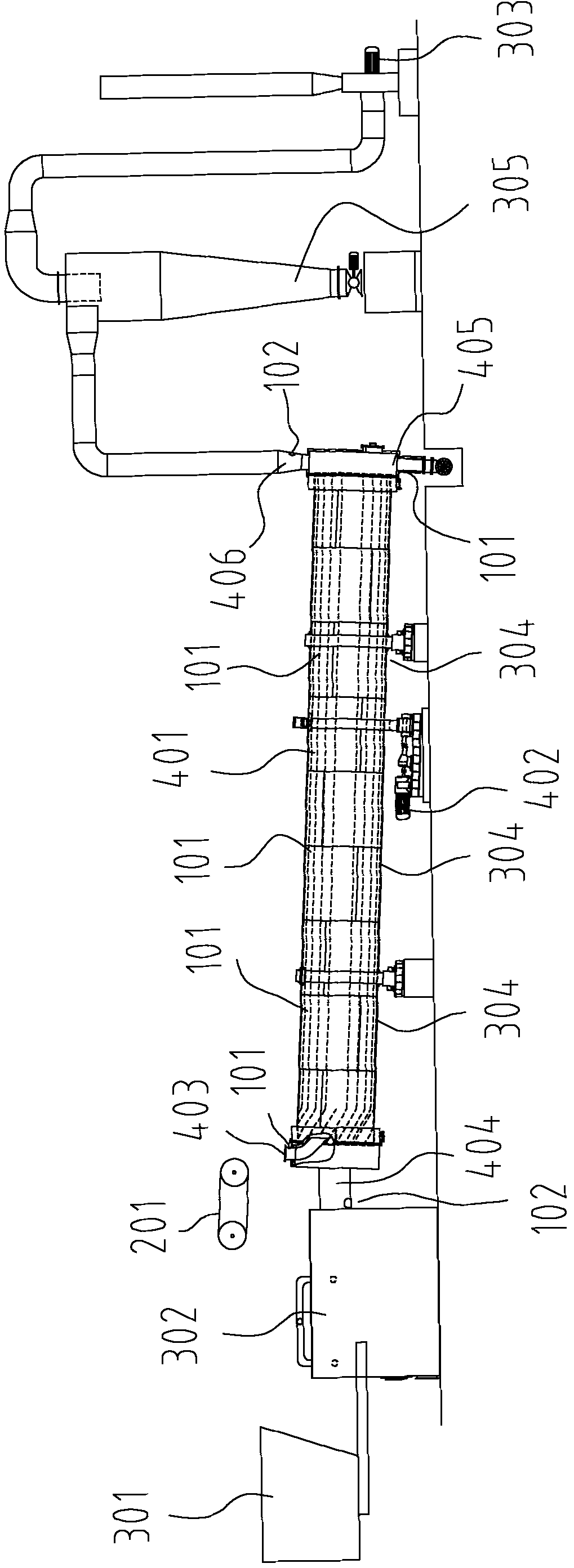

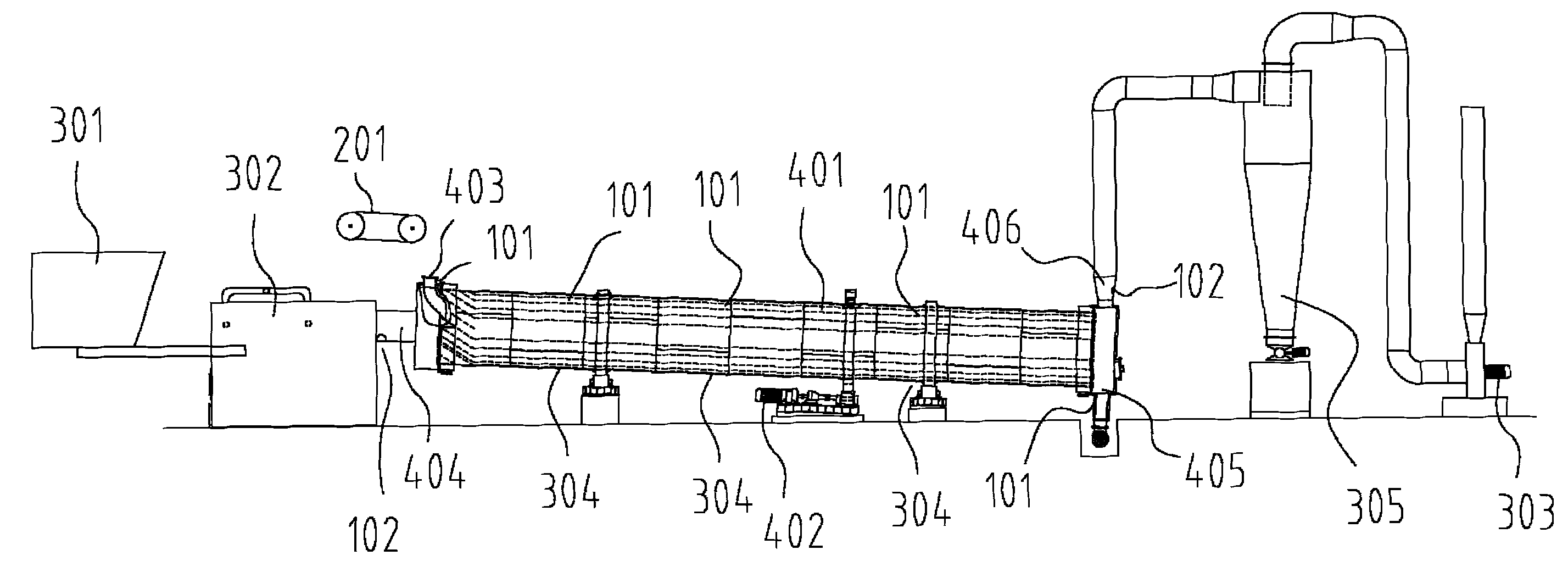

[0029] see figure 1, the biomass drying control method of this embodiment is applied in a drum-type biomass drying system, which belongs to an open drying method. The drum-type biomass drying system includes a feeding device, a heating device, a drying Drying device and control device, feeding device, heating device are connected with drying device respectively, and control device comprises control unit (not shown in the figure) and the humidity sensor 101 that is connected with this control unit, and control unit is connected with feeding device, supplying device respectively. Heating device, drying device connection. The control unit is a single-chip microcomputer including a programmable controller, and other computer systems that can realize industrial control can also be selected; the feeding device is a belt-type feeding mechanism 201, and the control unit controls the speed of the belt to ensure that it enters the oven. The biomass in the drying device meets the requir...

Embodiment 2

[0032] In the biomass drying control method of this embodiment, the applied biomass drying system is divided into three areas in the drum 401 along the axial direction, which are the first area, the second area and the third area. Humidity sensors 101 are also respectively provided in the three areas. Preferably, the humidity sensors 101 are evenly distributed along the circumferential direction of the drum 401 so that the humidity data of the biomass can be collected more accurately. Other structures and embodiments of the biomass drying system One's the same. When the biomass to be dried passes through the first area, the humidity sensor 101 in this area measures the humidity of the biomass to be dried. If there is no instruction, if the humidity of the biomass to be dried is too low, the control unit will issue an instruction to increase the inclination angle of the drum 401 or / and the speed of the drum to increase the speed of the biomass traveling in the drum and shorten ...

Embodiment 3

[0034] In the biomass drying control method of this embodiment, the control device of the biomass drying system applied further includes a temperature sensor 102 connected to the control unit, and the temperature sensors 102 are respectively arranged at the hot air inlet of the drum 401 404 and the hot air outlet 406, other structures of the biomass drying system are the same as those of the second embodiment. According to the temperature sent back by the temperature sensor, the control unit can control the amount of fuel in the hot blast stove according to the specific situation, increase or decrease the temperature in the drum, and achieve more precise drying control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com