Method and device for performing multi-spectral detection on surface quality of fabrics

A surface quality, textile technology, applied in the field of photoelectric detection, can solve the problems of loss, uneven dyeing, single function, etc., and achieve the effect of reducing volume and manufacturing cost, broad application prospects, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. However, those skilled in the art should recognize that the following implementations are only exemplary, and are intended to better enable those skilled in the art to understand the patent, and should not be construed as limiting the scope of the patent; as long as Any equivalent changes or modifications based on the spirit disclosed in this patent and similar structures, methods and similar changes thereof all fall within the scope of this patent.

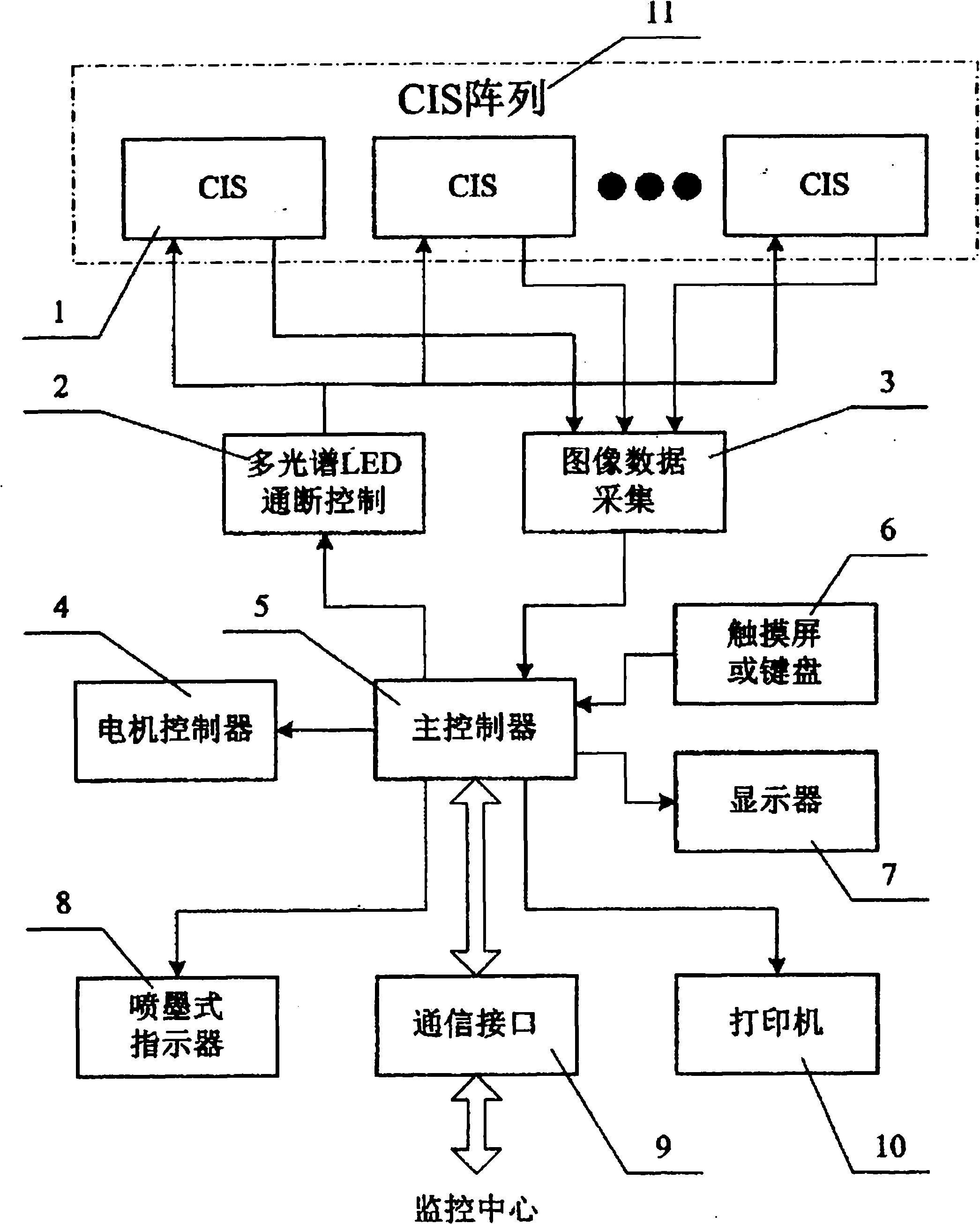

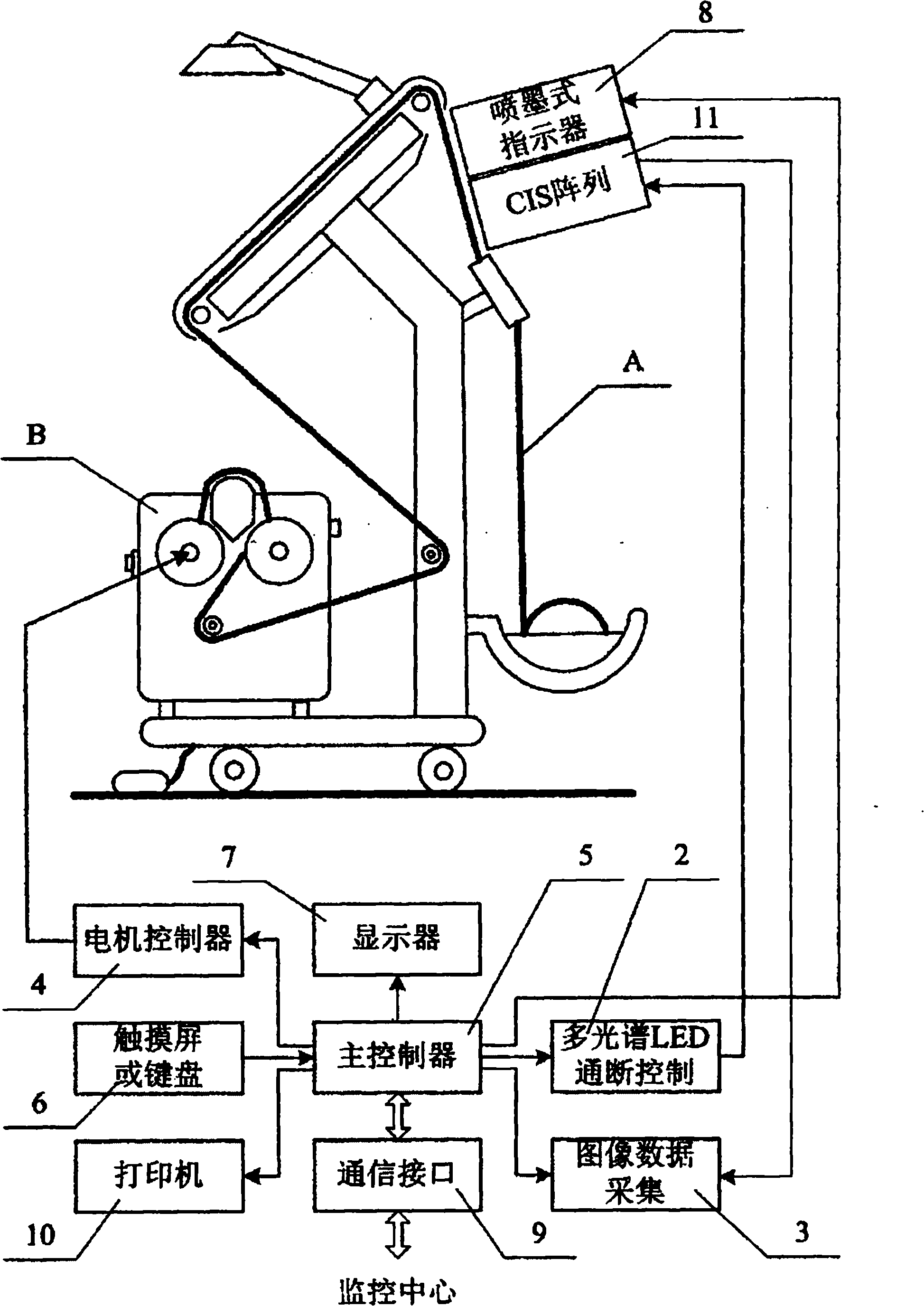

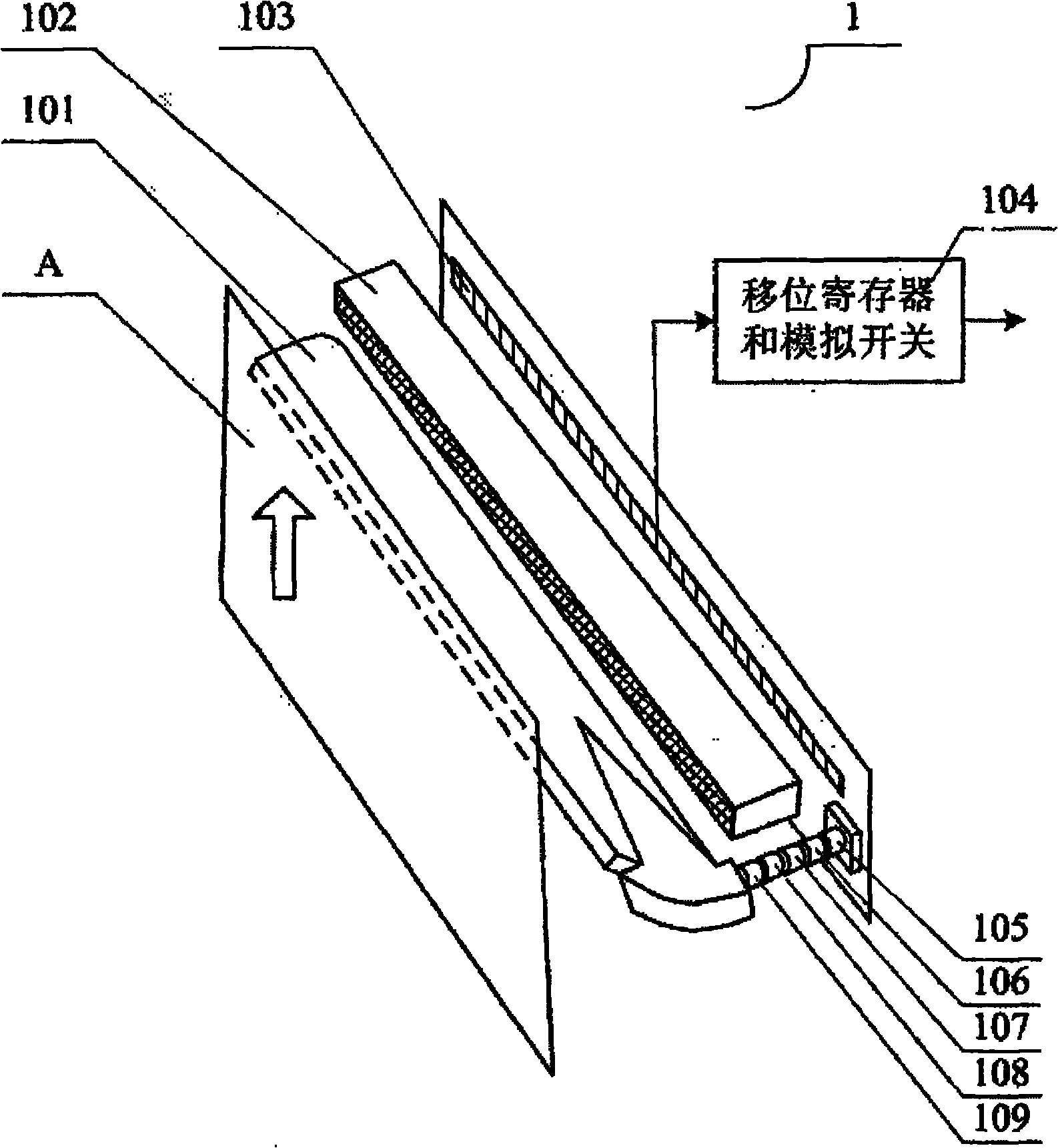

[0025] see figure 1 and figure 2 , said a kind of textile surface quality multi-spectral detection device is composed of contact image sensor (CIS) 1 CIS array 11, multi-spectral LED on-off control 2, image data acquisition 3, motor controller 4, main control Device 5, touch screen or keyboard 6, display 7, inkjet indicator 8, communication interface 9 and printer 10. The main controller 5 controls the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com