Test device for static properties of triaxial miniature accelerometer and test method thereof

An accelerometer and static performance technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measurement devices, etc., can solve the problem of reducing measurement accuracy, complex structure, and improving measurement efficiency etc. to achieve the effect of reducing test cost, simplifying the overall structure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

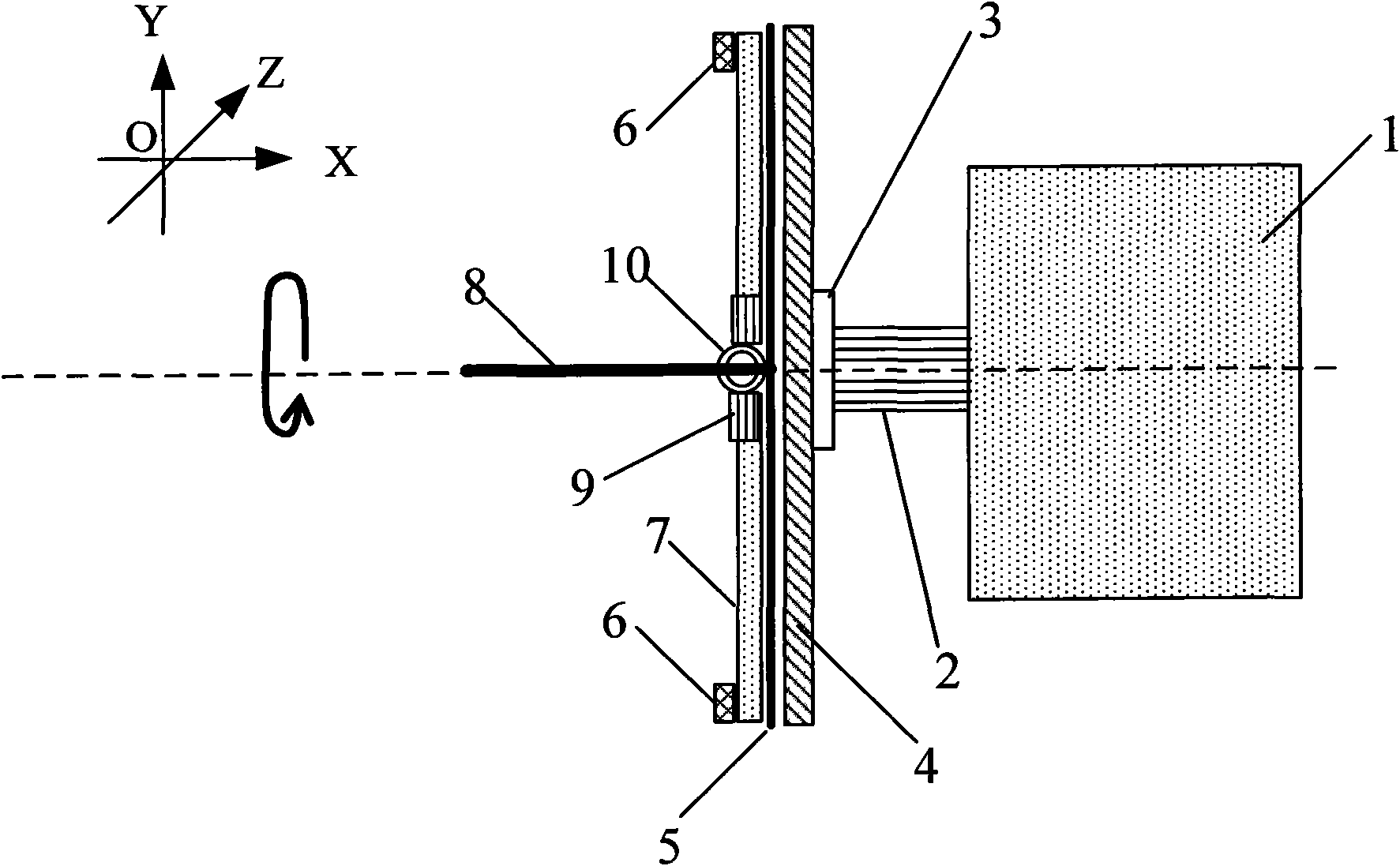

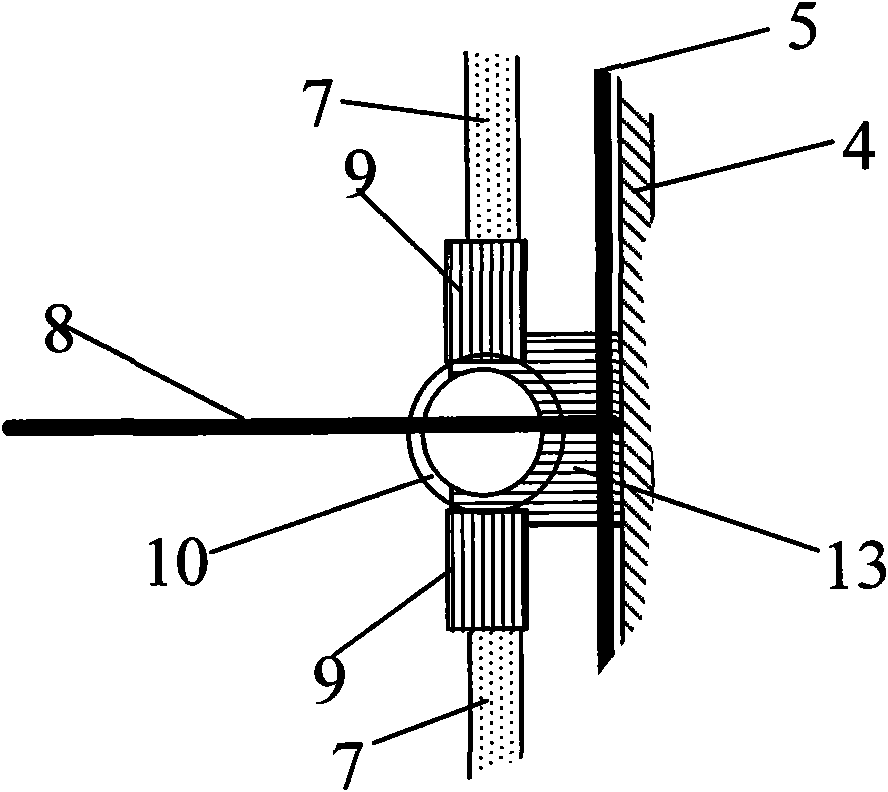

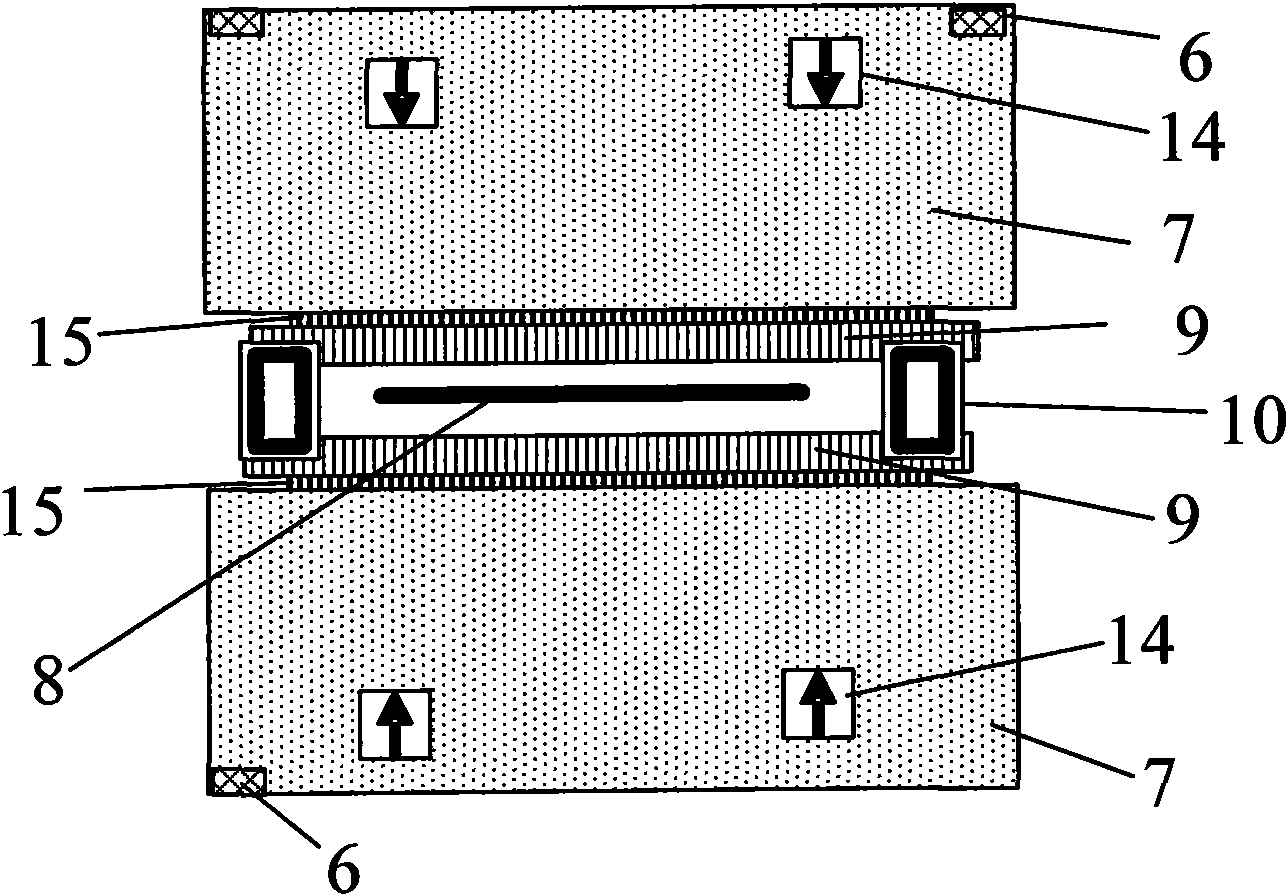

[0027] The invention provides a test device and a test method for the static performance index of a three-axis miniature accelerometer. like Figure 1-5 As shown, the device for testing the typical performance indicators of the three-axis micro accelerometer in the present invention includes: motor 1, transmission shaft 2, flange 3, test motherboard 4, Y direction positioning plate 5, spacer block 6, test board 7, X direction The positioning board 8 , the slot 9 , the rotating device 10 , the connecting device 13 , the positioning slot 14 of the device under test and the lead bar 15 on the test board 7 . The motor 1 provides power for the rotation of the test platform, and the test platform can rotate along the direction of rotation; the transmission shaft 2 is the power transmission de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com