Image pickup lens, image pickup apparatus, mobile terminal, method for manufacturing image pickup lens, and method for manufacturing image pickup apparatus

一种摄影镜头、制造方法的技术,应用在摄影镜头领域,能够解决量产性恶化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

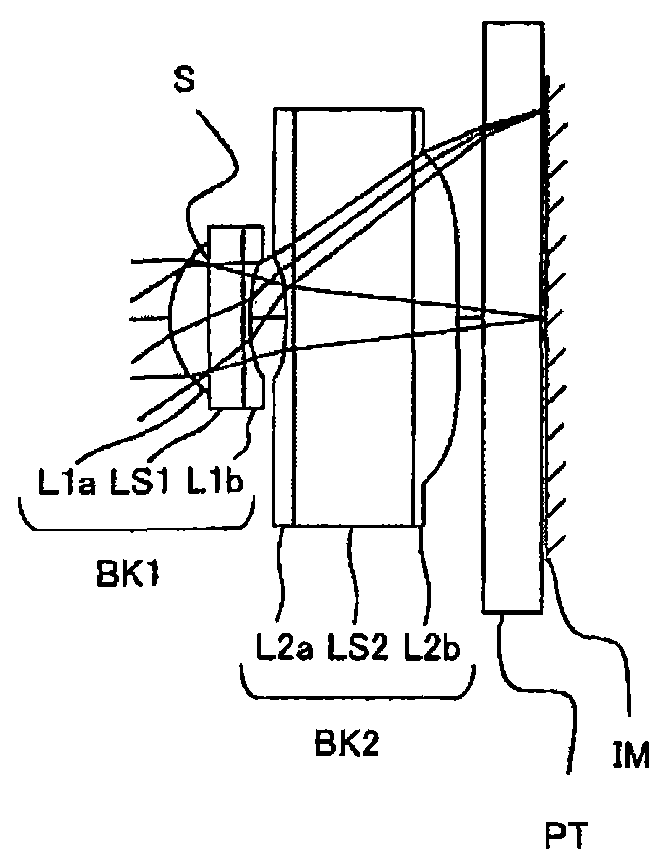

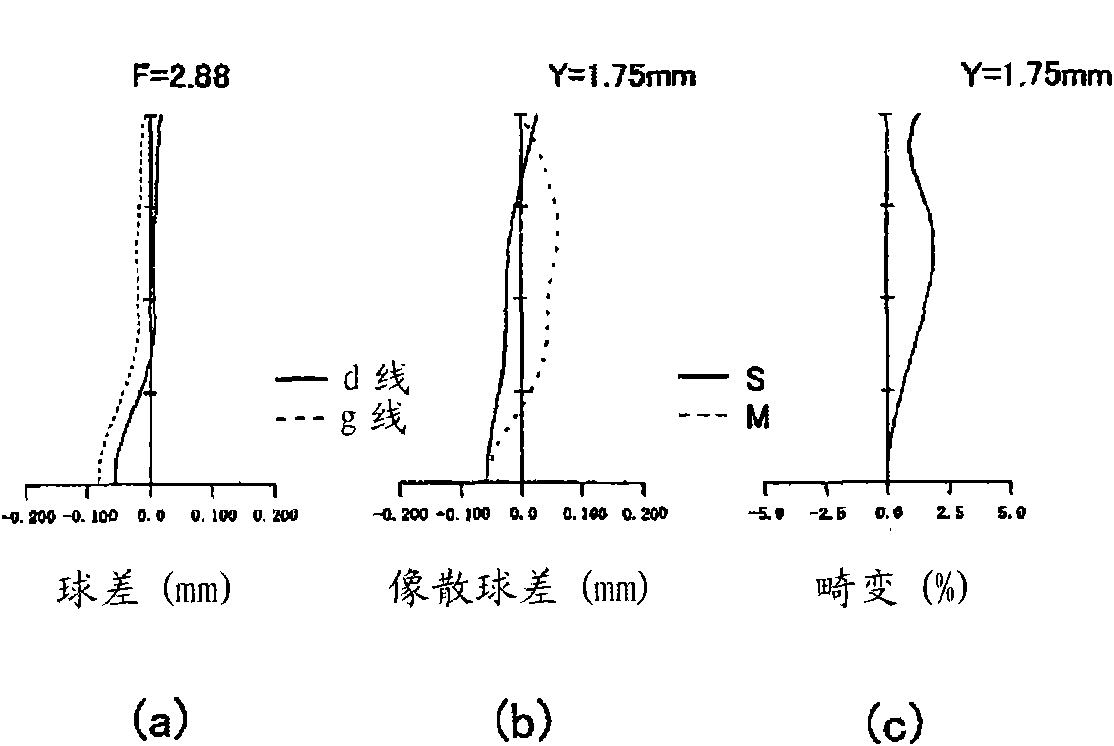

[0219] Table 1 shows the lens data of Example 1. Figure 6 It is a sectional view of the photographing lens shown in Example 1. Figure 7 It is an aberration diagram (spherical aberration (a), astigmatism (b), distortion (c)) of Example 1. Here, in the spherical aberration diagram, the solid line indicates the spherical aberration amount for the d-line, the dotted line indicates the spherical aberration amount for the g-line, and in the astigmatism diagram, the solid line indicates the sagittal plane, and the dotted line indicates the meridional plane (hereinafter same as in the aberration map). The photographing lens of Example 1 is provided in order from the object side: 1a lens portion L1a convex on the object side, aperture stop S, first lens substrate LS1, and 1b lens portion L1b concave on the image side 1st lens group BK1, followed by 2nd lens group BK2 consisting of 2a lens part L2a concave on the object side, 2nd lens substrate LS2, and 2b lens part L2b, and finally...

Embodiment 2

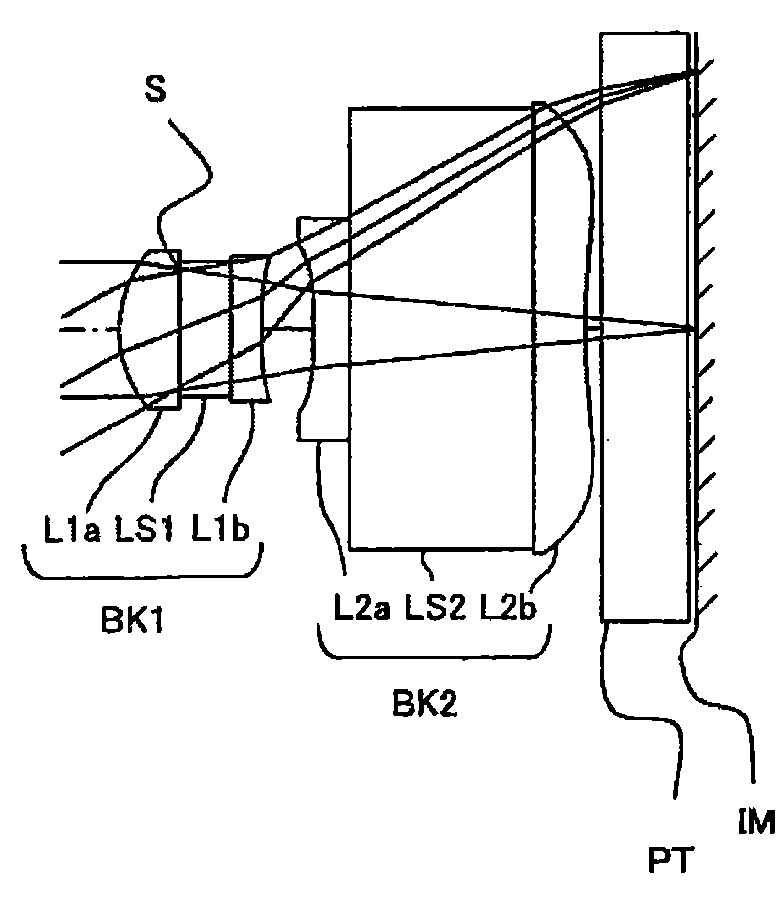

[0269] Table 2 shows the lens data of Example 2. Figure 8 It is a cross-sectional view of the photographic lens shown in Example 2. Figure 9 It is an aberration diagram (spherical aberration (a), astigmatism (b), distortion (c)) of Example 2. The photographing lens of Example 2 is provided in order from the object side: a 1a lens portion L1a convex on the object side, an aperture stop S, a first lens substrate LS1, and a 1b lens portion L1b concave on the image side 1st lens group BK1, followed by 2nd lens group BK2 consisting of 2a lens part L2a concave on the object side, 2nd lens substrate LS2, and 2b lens part L2b, and finally a hypothetical optical low-pass filter, Parallel plate PT for infrared cut filters, sealing glass for solid-state imaging devices, etc. IM is the imaging plane of the imaging element. In addition, all the surfaces of the lens portion that are in contact with air are aspherical.

[0270] In Example 2, the refractive index nI with respect to the ...

Embodiment 3

[0319] Table 3 shows the lens data of Example 3. Figure 10 It is a cross-sectional view of the photographing lens shown in Example 3. Figure 11 It is an aberration diagram (spherical aberration (a), astigmatism (b), distortion (c)) of Example 3. The photographic lens of Example 3 is provided in order from the object side: a 1a lens portion L1a convex on the object side, an aperture stop S, a first lens substrate LS1, and a 1b lens portion L1b concave on the image side 1st lens group BK1, followed by 2nd lens group BK2 consisting of 2a lens part L2a concave on the object side, 2nd lens substrate LS2, and 2b lens part L2b, and finally a hypothetical optical low-pass filter, Parallel plate PT for infrared cut filters, sealing glass for solid-state imaging devices, etc. IM is the imaging plane of the imaging element. In addition, all the surfaces of the lens portion that are in contact with air are aspherical.

[0320] In Example 3, the refractive index nI with respect to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com