linear compressor

A linear compressor and space compression technology, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve problems such as difficult to manage the size of various components, detachment of discharge cover components, refrigerant leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, a linear compressor according to an embodiment of the present invention will be described in detail with reference to the drawings.

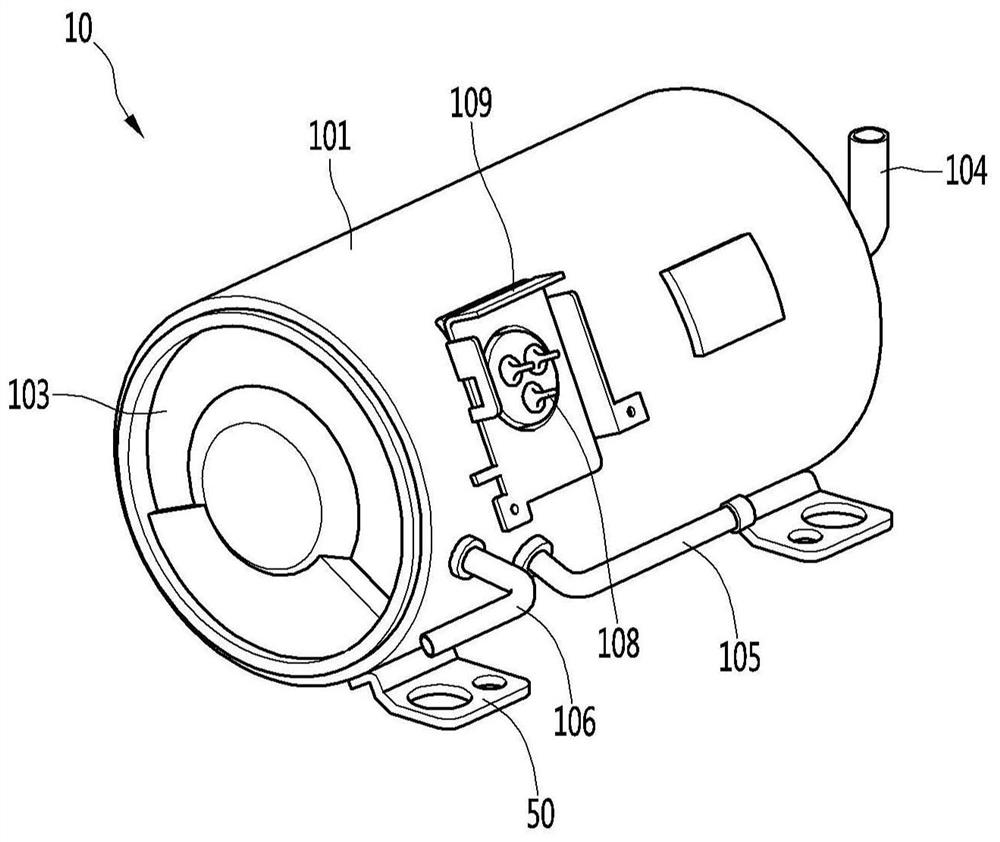

[0042] figure 1 It is a perspective view of the linear compressor of the first embodiment of the present invention.

[0043] refer to figure 1 , The linear compressor 10 of the embodiment of the present invention may include: a shell 101 forming an appearance; and a pair of shell covers coupled to both ends of the shell 101 . As an example, the housing 10 may have a cylindrical shape. The pair of case covers may include: a first case cover 102 (refer to image 3 ); and the second housing cover 103 on the refrigerant discharge side.

[0044] Specifically, a leg 50 may be combined on the lower side of the housing 101 . The feet 50 may be combined with a base of a product for setting the linear compressor 10 . As an example, the product may include a refrigerator, and the base may include a base of a machine compartment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com