Dust explosion device

A technology of dust explosion and ignition device, which is applied in the field of teaching instruments, can solve the problems of teachers using computers and multimedia without electricity, large side effects, etc., and achieves the effects of low dryness requirement, convenient operation and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

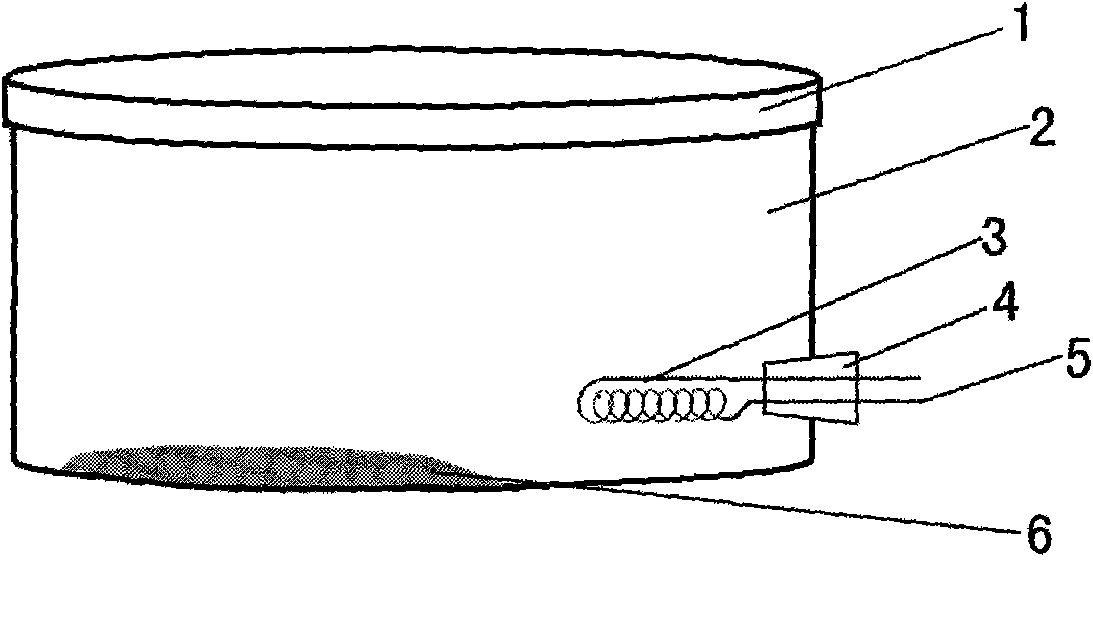

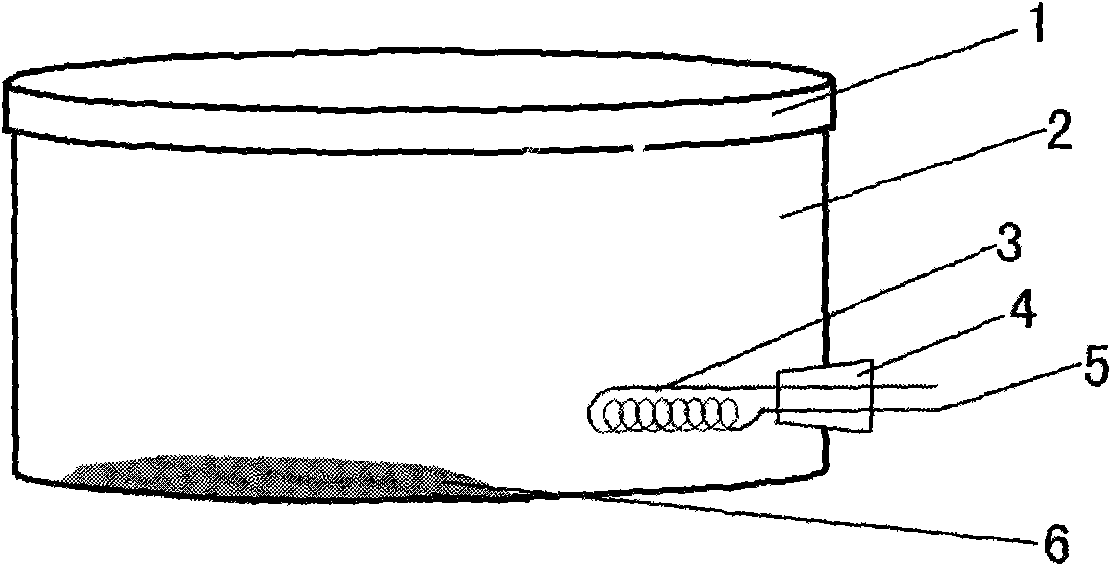

[0012] Such as figure 1 As shown, the outer cover 1 is connected above the opening end of the container 2 by extrusion. The joint of the outer cover 1 and the container 2 should be tight and suitable. If it is too loose, the effect will be poor, and if it is too tight, the firecrackers will be too powerful. There can be no threaded thread openings on the inner wall and the outer wall of the open end.

[0013] The interior of the container 2 is provided with a spiral heating wire 3 with a resistance value of about several ohms. The spiral inner cavity of the heating wire 3 is used to clamp one or several match heads, that is, the diameter of the spiral inner cavity should be equivalent to the diameter of one or several matchsticks. The bottom of container 2 places powdered combustibles 6 .

[0014] The heating wire is externally connected to the low-voltage power supply for ordinary teaching through the electric connection line, which can directly pass through the container w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com