Method and system for etching wafer back

A crystal back and etching technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as reducing the quality of semiconductor chips and discoloration of the front of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

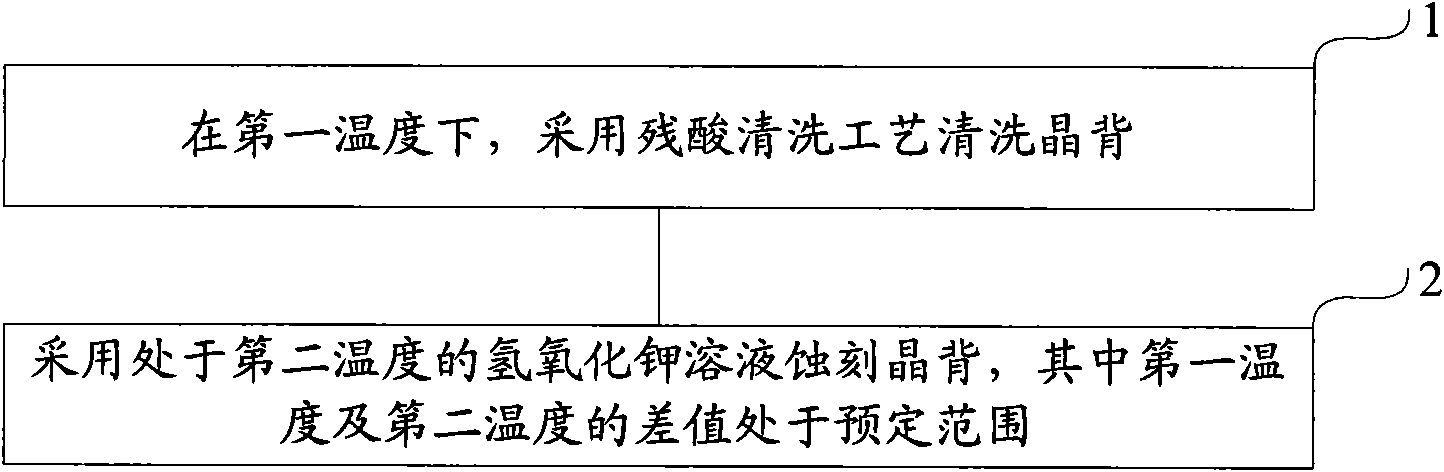

[0027] Aiming at the problem of discoloration of the front side of the wafer mentioned in the background technology, the inventors of the present application obtained by analyzing the existing crystal back etching process. Due to the large temperature difference in each step in this process, for example, the temperature of step a1 and step a2 changes from 60°C to The temperature from step a2 to step a3 increases from 23°C to 70°C, so that the acid-proof film attached to the front of the wafer expands with heat and contracts with cold, resulting in stretching and contraction, resulting in a gap between the acid-proof film and the glue. Cracks are formed or even separated, and the glue is used to bond the acid-proof film and the wafer. The acid from each step of the etching process will then enter the front side of the wafer through the above-mentioned cracks and separation cracks, forming residual acid or a by-product after the acid reacts with the wafer. In addition, through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com