Main transformer differential protection CT polarity check method of pumped storage power station

A pumped-storage power station and main transformer technology, applied in the measurement of electrical variables, emergency protection circuit devices, instruments, etc., can solve the problem of the inability to verify the CT polarity of the main transformer differential protection, and reduce the production cost and save investment. , the effect of simple operation and use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

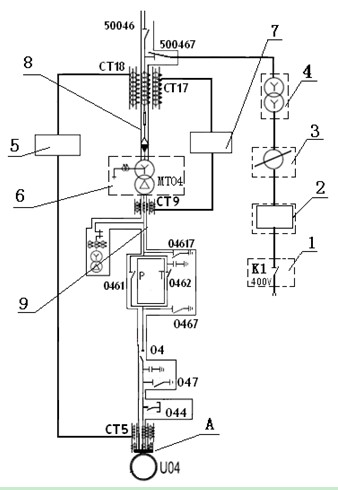

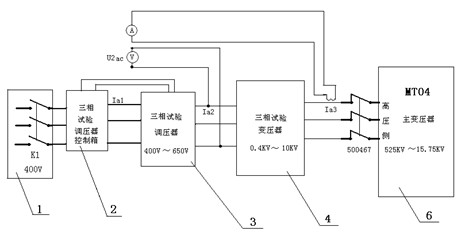

[0023] Embodiment 1: Taking a main transformer with a capacity of 360MVA and 500KV as an example to introduce the polarity verification method of the differential protection of the main transformer.

[0024] (1) The polarity verification method of the differential protection of the main transformer of the present invention is the short-circuit step-up method on the low-voltage side of the main transformer or the method of externally applied power supply.

[0025] (2) Test conditions of the method of the present invention: the capacity of the main transformer 6 of the present invention is 360MVA, the rated voltage is 525KV / 15.75KV (intermediate gear), the rated current is 396A / 13197A, the connection group label is YN d11, the short circuit impedance It is 14% (this value can be obtained by querying the parameters of the main transformer).

[0026] The equipment prepared for the verification of the present invention includes: a power inlet switch K1, a three-phase test voltage...

Embodiment 2

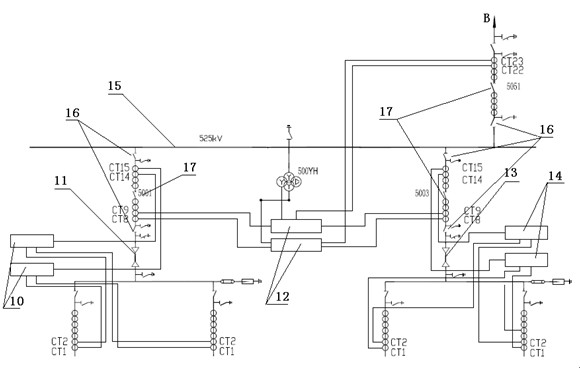

[0060] Embodiment 2: Using the method for verifying the polarity of the differential protection of the main transformer of the present invention, the CT polarity of the differential protection of the 500KV GIS bus 15, the first high-voltage cable 11, and the second high-voltage cable 13 of the power station is checked. Its differential protection CT configuration diagram is as follows: image 3 . Before the primary equipment is officially powered on, it is necessary to complete the busbar differential protection A\B set 12, the first high-voltage cable 11, the second high-voltage cable 13, the first differential protection A\B set 10, the second high-voltage CT polarity verification of A\B sets 14 of cable differential protection. The capacity of the test equipment only needs to be considered plus the charging current of the first and second high-voltage cables, and the pressure point is selected at image 3 In point B, the applied voltage is not affected by figure 1 Medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com