Slideway-type workpiece transmission device

A conveying device and slideway type technology, applied in the field of slideway type workpiece conveying device, can solve the problems of inability to meet mass production, difficulty in improving transportation efficiency, accidental damage of transported parts, etc. The effect of improving production efficiency, safety, and conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

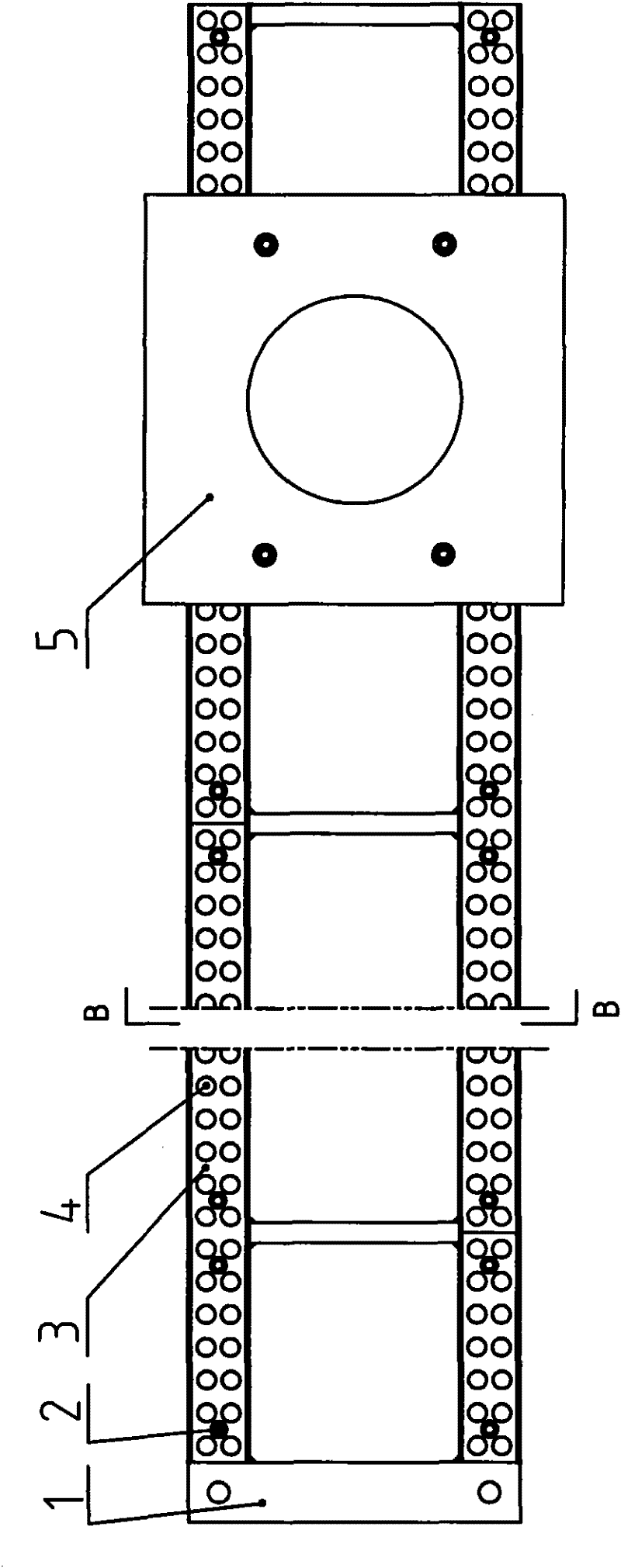

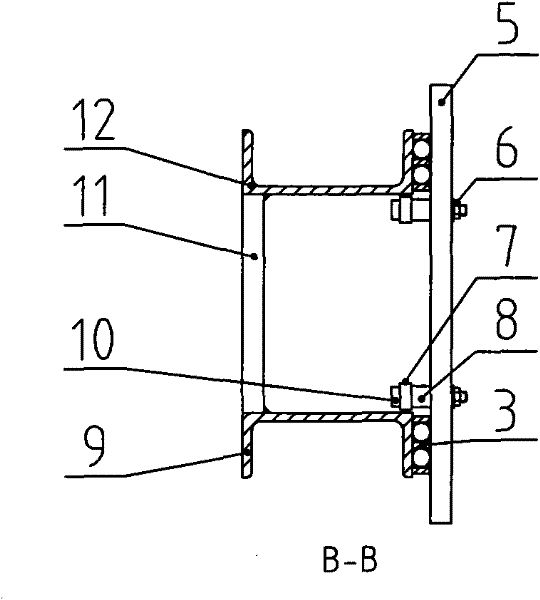

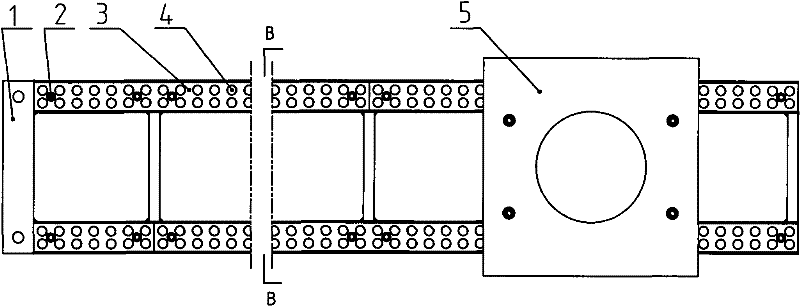

[0011] figure 1 figure 2 As shown, the slideway workpiece conveying device is mainly composed of a slideway bracket 1, a slideway plate 3 and a supporting plate 5. Slideway support 1 is made of the left channel steel 12 and the right channel steel 9 that two grooves are symmetrically arranged outwards, the plurality of connecting plates 11 welded at the bottom of the left channel steel 12 and the right channel steel 9 at intervals, and the left channel steel 12 and the right channel steel The top of the channel steel 9 is respectively provided with a slideway plate 3 having the same width as its groove side, and the contact surface between the slideway plate 3 and the left channel steel 12 and the right channel steel 9 is provided with a fixing screw 2; the slideway plate 3 is processed with A plurality of round holes, a plurality of round holes are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com