W-type low-and-medium temperature NTC-PTC binary composite thermistor material and preparation method thereof

An NTC-PTC and thermistor technology, which is applied to the W-type medium and low temperature NTC-PTC dual composite thermistor material and its preparation field, can solve the problems of environmental pollution, excessive raw material involvement, breakdown, etc., and can be widely used effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The preparation process and steps of this embodiment are as follows:

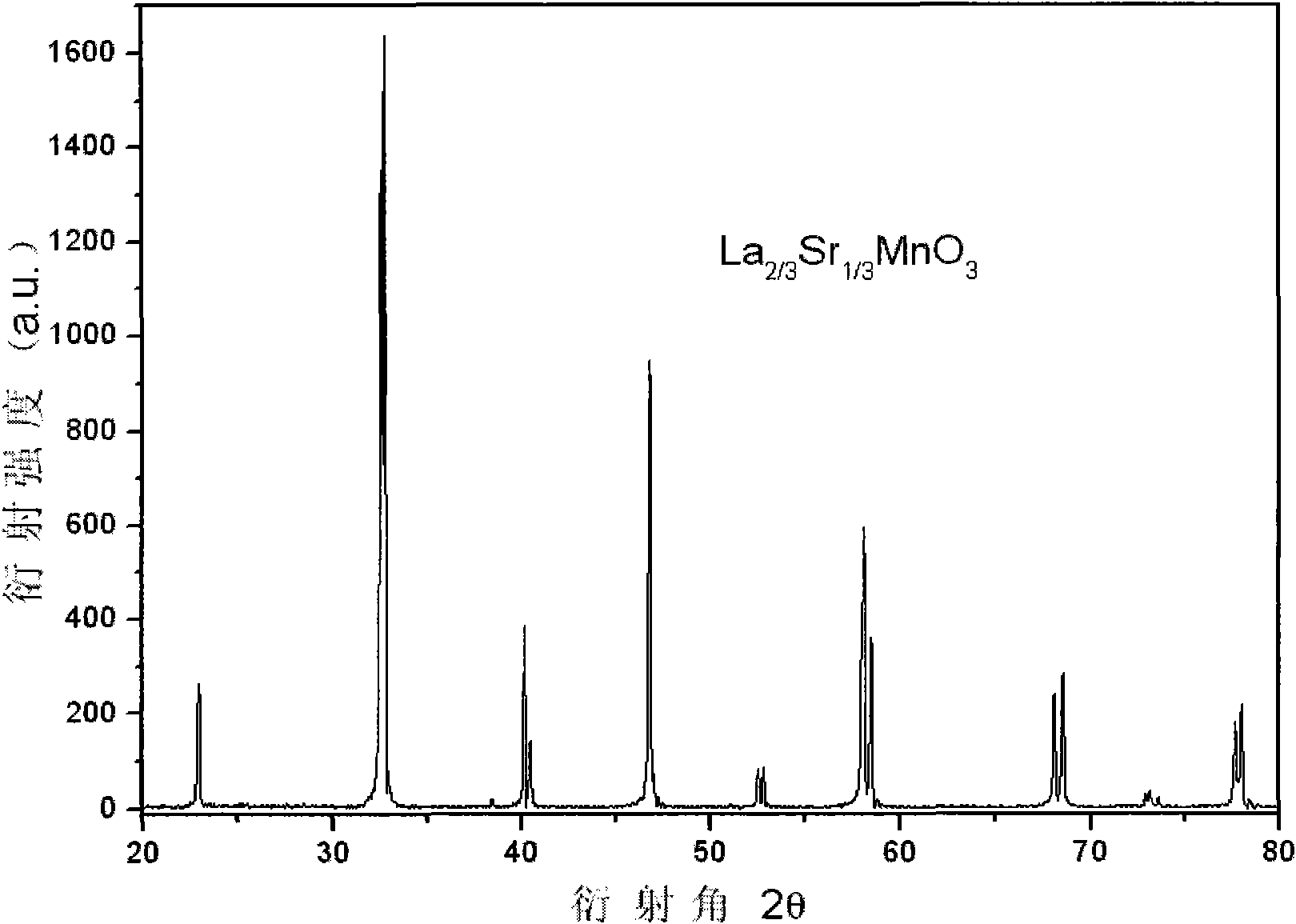

[0034] 1. Preparation of La 2 / 3 Sr 1 / 3 MnO 3 main phase compound

[0035] 1) Weigh high-purity SrCO containing three metal elements La, Sr and Mn according to the stoichiometric ratio 3 、La 2 o 3 with MnO 2 Compounds used to prepare the main phase La 2 / 3 Sr 1 / 3 MnO 3 compound;

[0036] 2) Prepare the main phase La 2 / 3 Sr 1 / 3 MnO 3 The raw material mixture is ground in an agate mortar for 8-10 hours, and pre-fired at 800-1000°C for about 8-10 hours;

[0037] 3) Prepare the main phase La2 / 3 Sr 1 / 3 MnO 3 The raw material mixture is crushed by an agate mortar (particle size is less than 1um), and shaped by a tablet machine (molding pressure is 10-14MPa), and finally put into a crucible and sintered at 1250-1350°C in a muffle furnace. The sintering time It takes about 20 to 24 hours to form a phase after natural cooling;

[0038] 4) Put the phased La 2 / 3 Sr 1 / 3 MnO 3 Crushing and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com