Manufacture method of high-performance anticorrosion composite metal tube and novel color lean pipe

A composite metal pipe and manufacturing method technology, applied in metal material coating process, pipeline anti-corrosion/anti-rust protection, pipe/pipe joint/pipe fitting and other directions, can solve problems such as limited effect, achieve low cost, complete infiltration layer, Reasonable effect of raw material processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

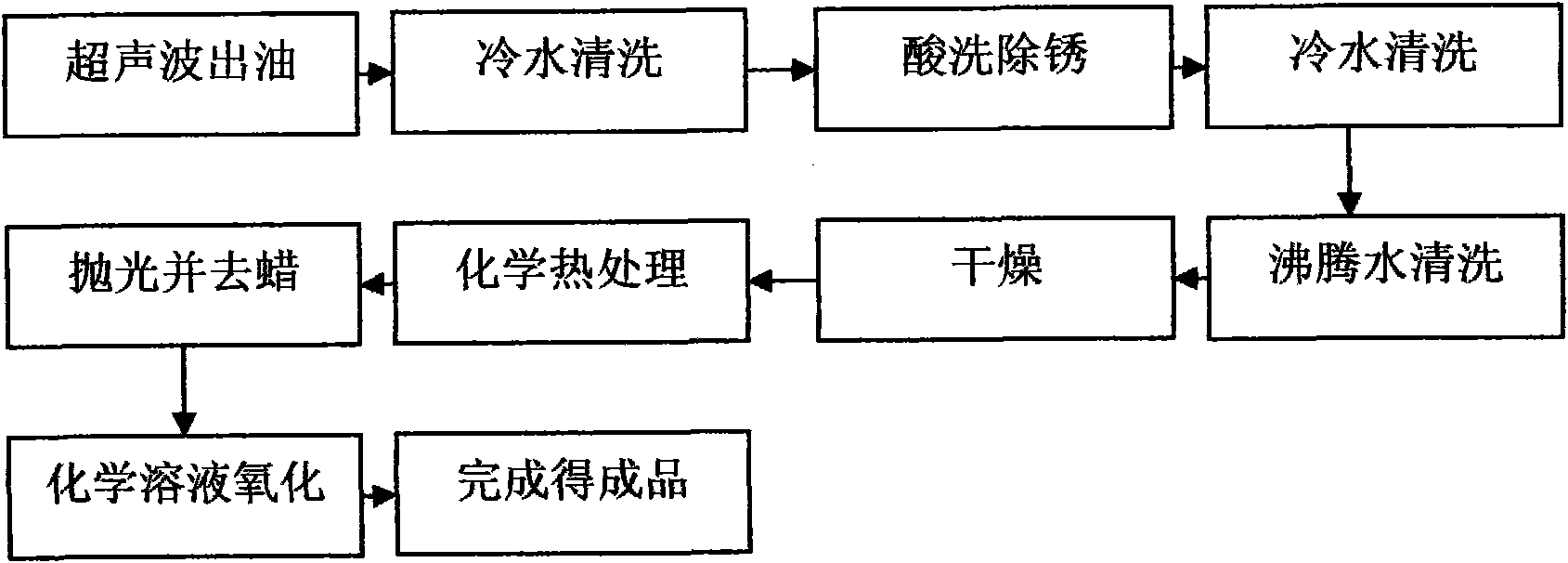

[0020] see figure 2 , a method for manufacturing a high-performance anti-corrosion composite metal pipe, characterized in that the method comprises the following steps:

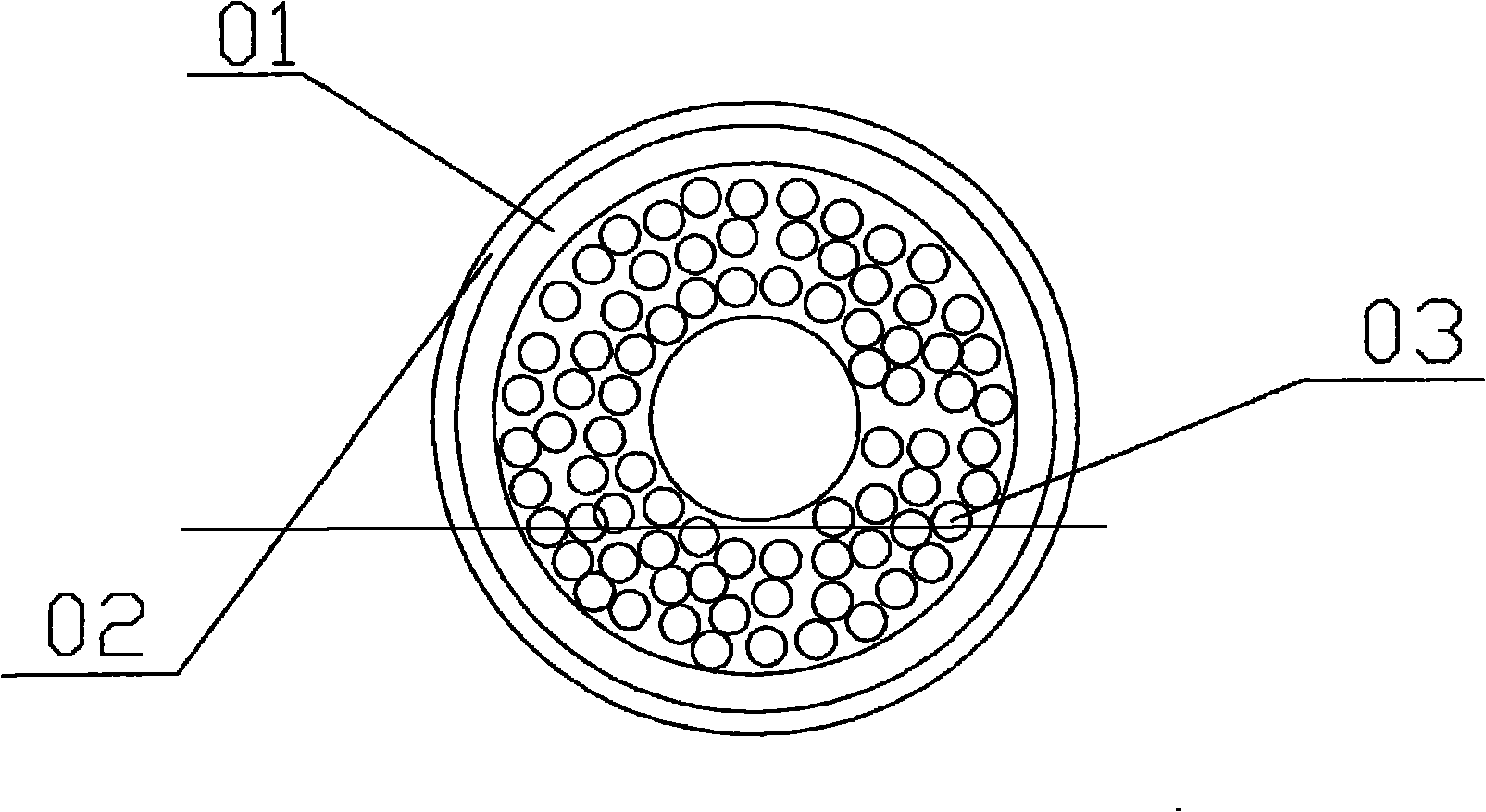

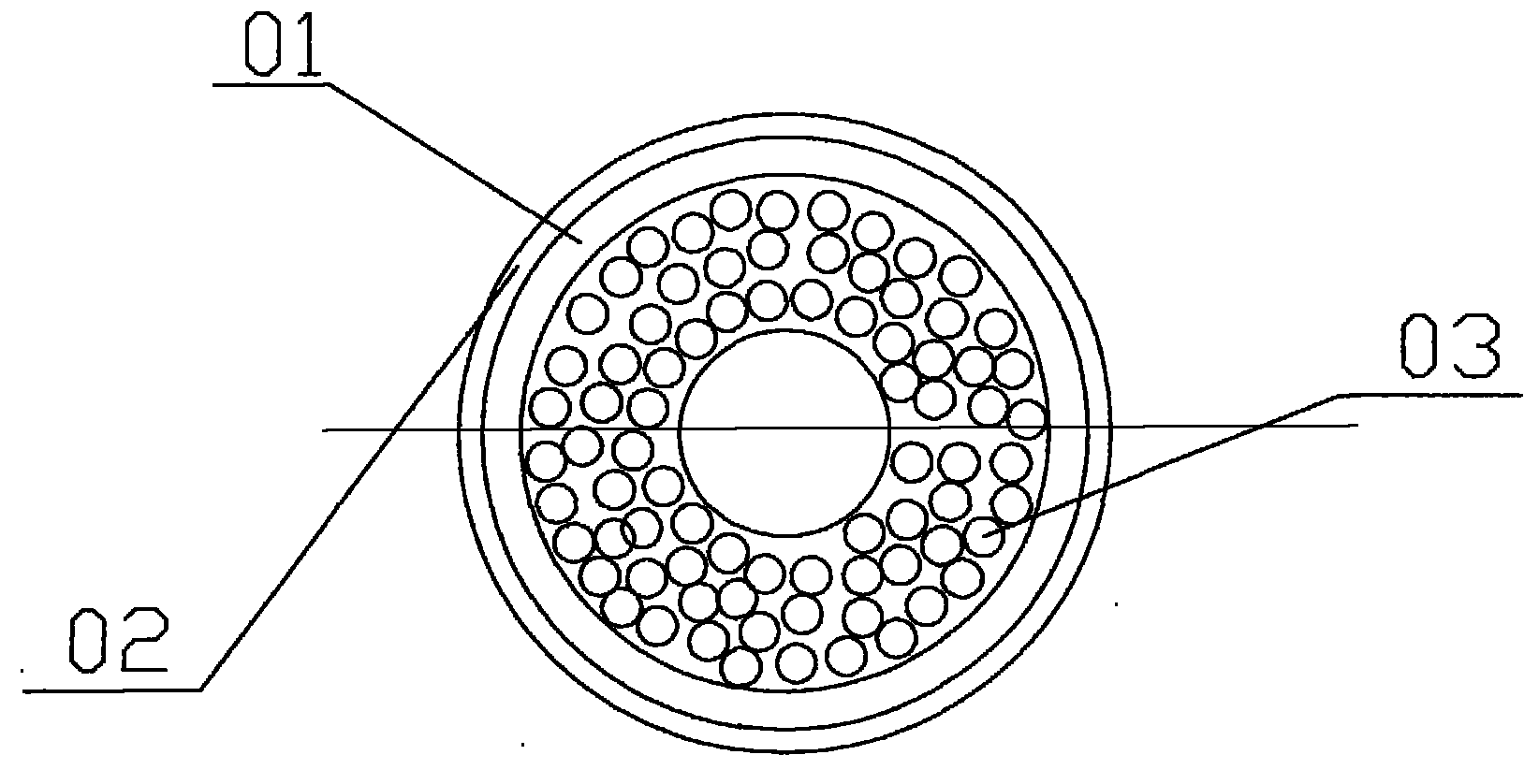

[0021] (1) Prepare a metal matrix pipe 03 and a soluble electrolyte containing activated aluminum elements; the soluble electrolyte containing activated aluminum elements is completely activated and separated in the solution after the metal activator in the electrolyte reacts with the aluminum element material Aluminum element electrolyte composition.

[0022] (2) Chemical heat treatment: remove oil and rust on the outer surface of the metal matrix pipe, then put the metal matrix pipe into the soluble electrolyte containing activated aluminum elements to react, remove the remaining aluminum on the surface of the material, and After the material is polished, the polishing wax is removed; the chemical heat treatment also includes a pretreatment method, and the pretreatment method includes ultrasonic degreasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com