Integrated fireproof exhaust pipeline for kitchen and bathroom and manufacturing method thereof

An exhaust duct, integrated technology, applied in vertical pipes, building components, buildings, etc., to ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

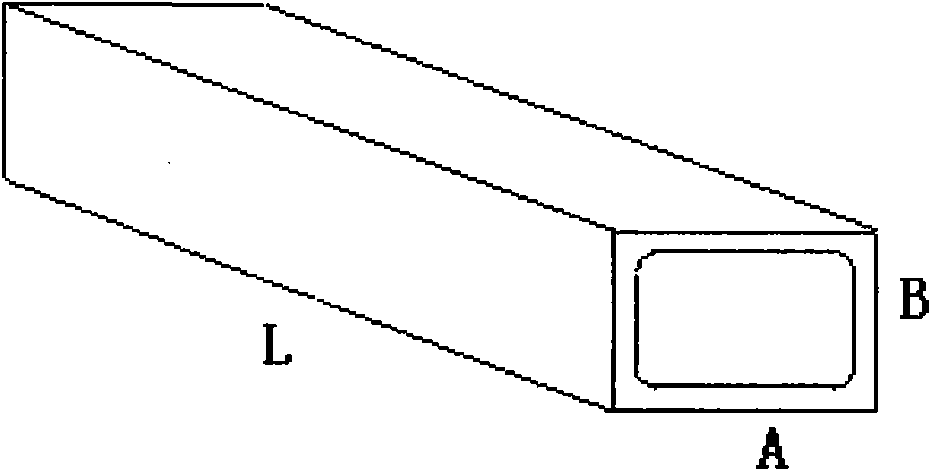

[0017] This embodiment is 250mm * 300mm * 3000mm * 8mm (cross-section length * cross-section width * pipe length * pipe wall thickness) integrated fireproof exhaust duct for kitchen and bathroom.

[0018] Its materials are composed of magnesium oxide, brine, vitrified microspheres, modifiers, short fibers, mesh cloth, fly ash, waste paper pulp, and sawdust. The formula of the exhaust channel is:

[0019] (1) Magnesium oxide material about 17kg;

[0020] (2) About 20kg of brine;

[0021] (3) Vitrified microbeads 2kg (about 17L);

[0022] (4) Sawdust 5kg;

[0023] (5) 3.5kg of fly ash;

[0024] (6) Modifier 0.18kg~0.2kg;

[0025] (8) Short fiber 0.2kg;

[0026] (9) Mesh cloth (grid cloth mesh aperture 4×4mm~10×10mm, mesh cloth weight 40~160g / m 2 ) appropriate amount.

[0027] The integrated kitchen and bathroom fireproof exhaust duct prepared by the above formula, the impact strength of the finished product is ≥1.5kj / m 2 , flexural strength ≥ 8Mpa, vertical bearing capac...

Embodiment 2

[0029] This embodiment is 250mm * 300mm * 3200mm * 8mm (cross-section length * cross-section width * pipe length * pipe wall thickness) integrated fireproof exhaust duct for kitchen and bathroom.

[0030] Its material is composed of low-alkalinity cement, vitrified microbeads, short fibers, and mesh cloth. The formula of the exhaust channel is:

[0031] (1) About 20kg of low alkalinity cement;

[0032] (2) Vitrified microbeads 25L;

[0033] (3) Short fiber 0.2kg;

[0034] (4) mesh cloth appropriate amount

[0035] (5) Appropriate amount of water

[0036] The integrated kitchen and bathroom fireproof exhaust duct prepared by the above formula, the impact strength of the finished product is ≥1.5kj / m 2 , flexural strength ≥ 8Mpa, vertical bearing capacity ≥ 90kn, combustion performance A1 level.

Embodiment 3

[0038] The embodiment of the present invention is 250mm×500mm×3000mm×10mm (cross-section length×cross-section width×pipe length×pipe wall thickness) integrated kitchen and bathroom fireproof exhaust duct.

[0039] Its material is composed of low-alkalinity cement, ceramsite sand, short fiber, and mesh cloth. The formula of the exhaust channel is:

[0040] (1) About 30kg of low alkalinity cement;

[0041] (2) Ceramsite sand about 30-40L;

[0042] (3) Short fiber 0.2kg;

[0043] (4) Hot-dip galvanized steel wire mesh (steel mesh mesh aperture 5×5mm~10×10mm,) appropriate amount;

[0044] (5) Appropriate amount of water

[0045] The integrated kitchen and bathroom fireproof exhaust duct prepared by the above formula, the impact strength of the finished product is ≥1.5kj / m 2 , flexural strength ≥ 8Mpa, vertical bearing capacity ≥ 90kn, combustion performance A1 level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com