Explosion-proof structure of energy-storing device

An explosion-proof structure and device technology, applied in structural parts, capacitor parts, electrical components and other directions, can solve the problems of narrow use range, inability to popularize energy storage devices, difficult to control explosion-proof pressure, etc., to achieve low cost, good explosion-proof effect, The effect of not easy to be damaged by external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

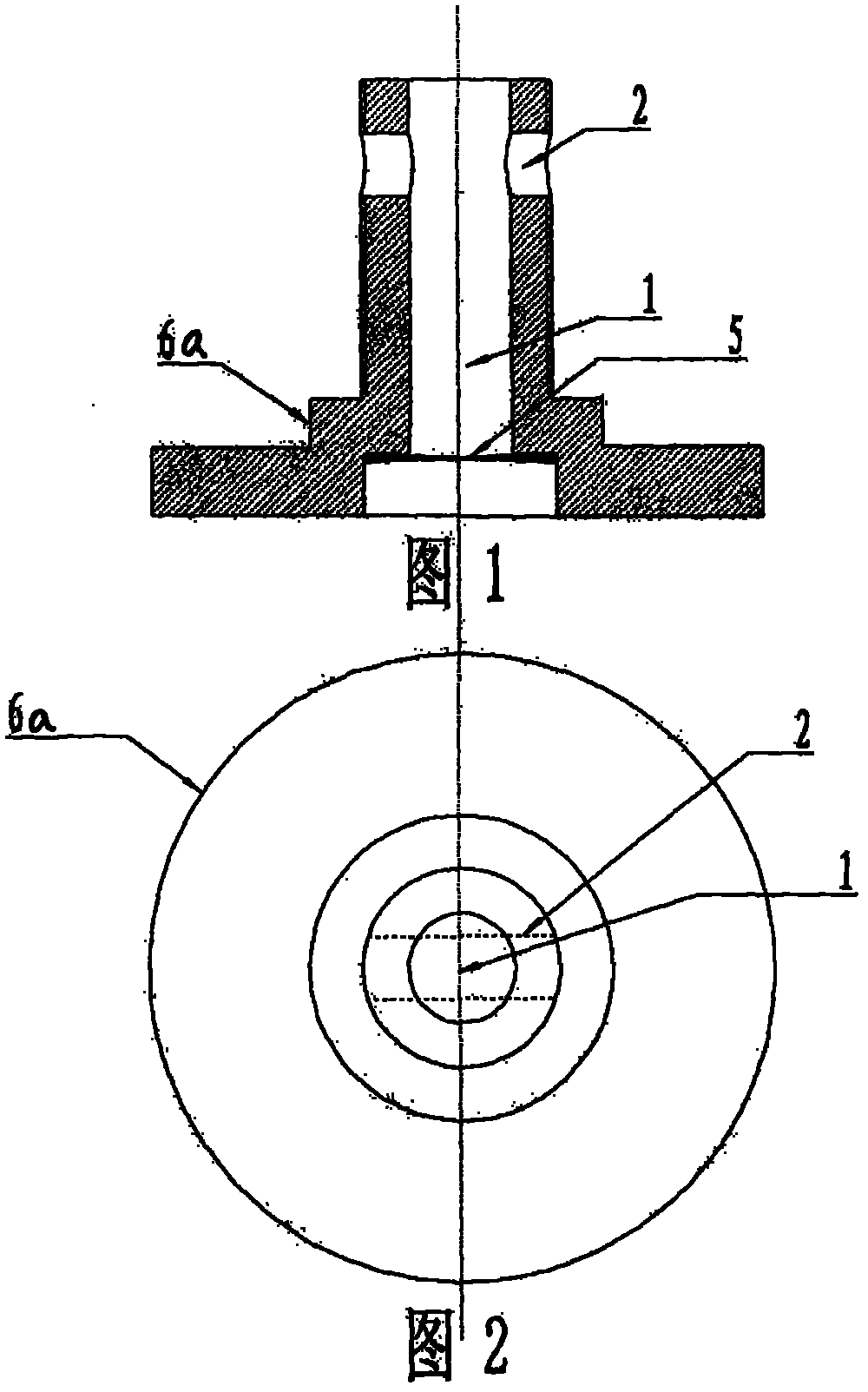

[0023] Such as figure 1 , figure 2 As shown, the positive electrode bolt 6a of the energy storage device is designed to have a circular axial through hole 1 and a radial hole 2 connecting the inside and outside of the energy storage device.

[0024] See figure 1 , the foil explosion-proof valve 5 is placed in the bottom of the circular axial through hole 1, the material of the positive bolt 6a is aluminum alloy of grade 3003; the shape of the explosion-proof valve 5 is designed to match the shape of the bottom of the axial through hole 1 Circular structure; explosion-proof valve 5 uses copper foil explosion-proof film. The explosion-proof valve 5 is placed inside the hole of the positive bolt 6a, so it is not easy to be damaged during production and use. The radial hole 2 is designed so that the internal pressure of the energy storage device can still be released when the axial through hole 1 is accidentally blocked.

Embodiment 2

[0026] Such as Figure 7 , Figure 4 As shown, the positive bolt 6a of the energy storage device is designed to have a circular axial through hole 1 connecting the inside and outside of the energy storage device, a radial hole 2 and a square groove 3 structure.

[0027] See Figure 7 , the explosion-proof valve 5 is placed in the bottom of the axial through hole 1, and the material of the positive bolt 6a is 6082 aluminum alloy; the shape of the explosion-proof valve 5 is designed to be a circular structure that matches the shape of the bottom of the axial through hole 1; Explosion-proof valve 5 selects aluminum foil explosion-proof film for use. The axial through hole 1 communicates with the outside through the radial hole 2 and the square groove 3. Compared with the embodiment 1, this design further protects the explosion-proof valve and prevents foreign objects from entering through the axial through hole 1 to block or damage the explosion-proof valve. Valve; if the radi...

Embodiment 3

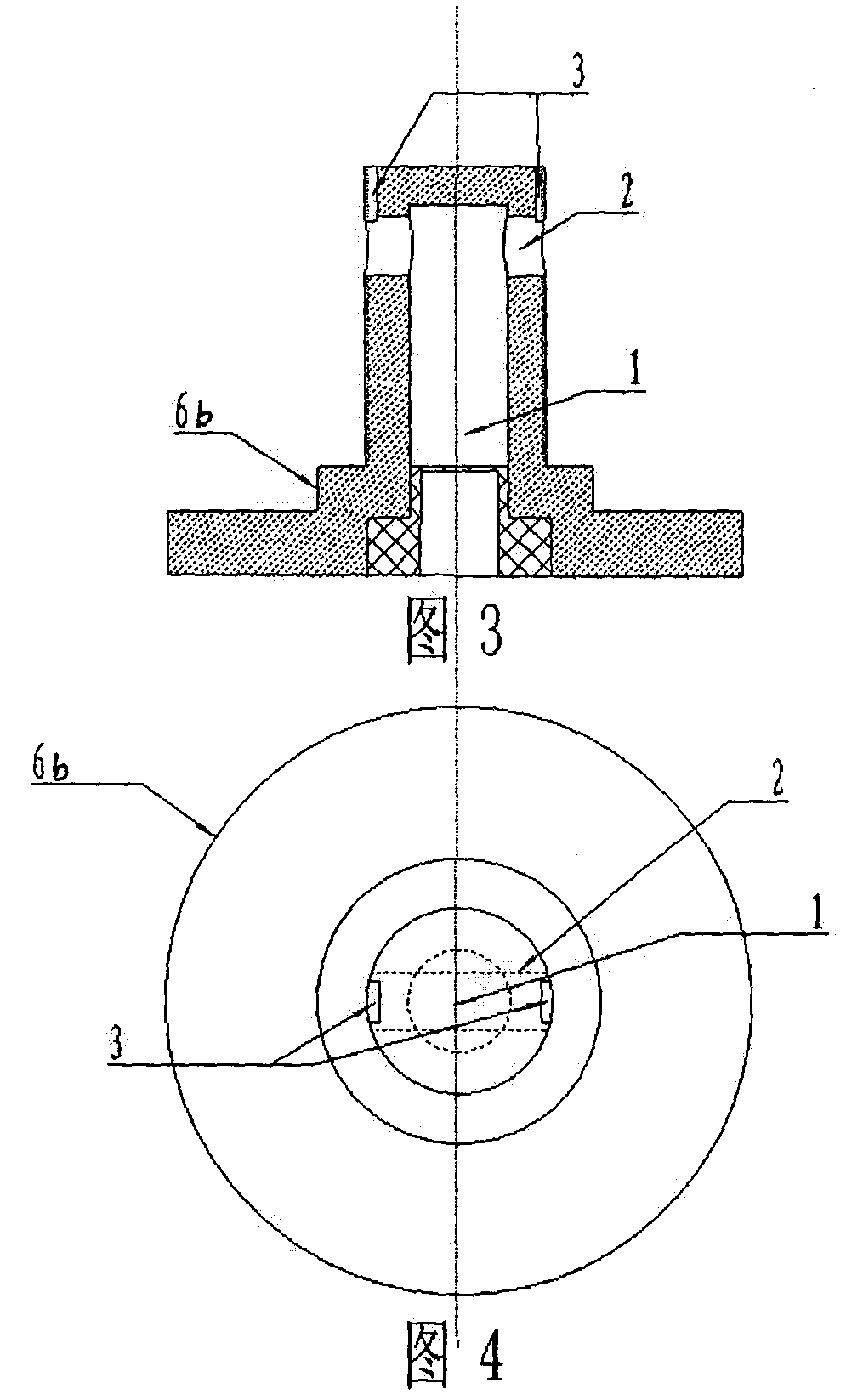

[0029] Such as image 3 , Figure 4As shown, the negative electrode bolt 6b of the energy storage device is designed to have a circular axial through hole 1 connecting the inside and outside of the energy storage device, a radial hole 2 and a square groove 3 structure.

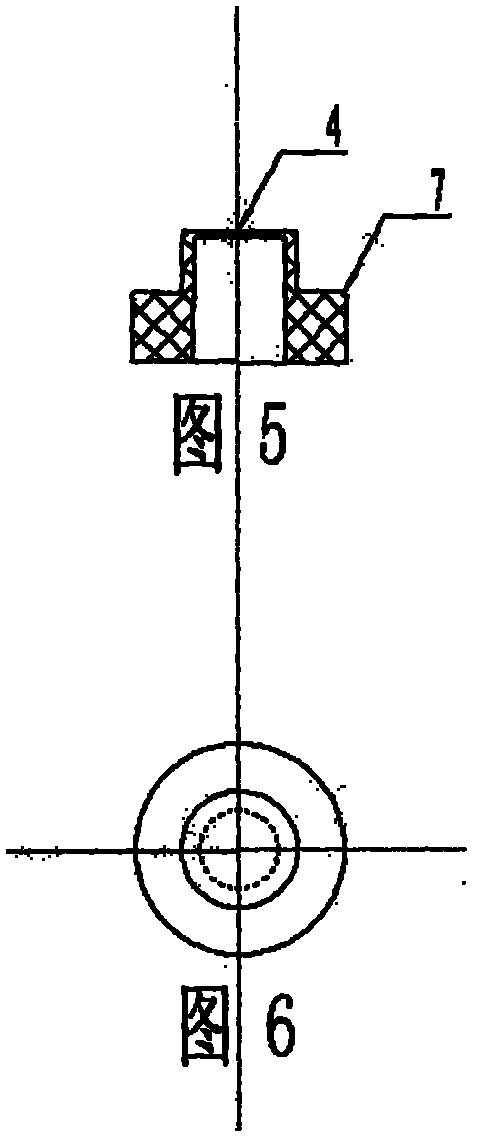

[0030] See image 3 , Figure 5 , put the rubber valve 7 into the bottom of the circular axial through hole 1, the material of the negative electrode bolt 6b is Pb59-1 lead brass alloy; the shape of the rubber valve 7 is designed to match the shape of the bottom of the circular hole 1 Structure; the material of the rubber valve 7 is natural rubber. Such as Figure 5 As shown, when the internal pressure of the energy storage device is higher than the maximum pressure that the rubber valve can withstand, the top 4 of the rubber valve will be burst to achieve the purpose of releasing the internal pressure of the energy storage device. According to the required explosion-proof pressure, the thickness of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com