Porcelain bushing type direct current field PLC/RI capacitor

A DC field and porcelain bushing technology, applied in DC circuits to reduce harmonics/ripples, etc., can solve the problems of small equipment capacitance requirements, high equipment cost, and large floor space, so as to save costs, The effect of cost reduction and floor space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

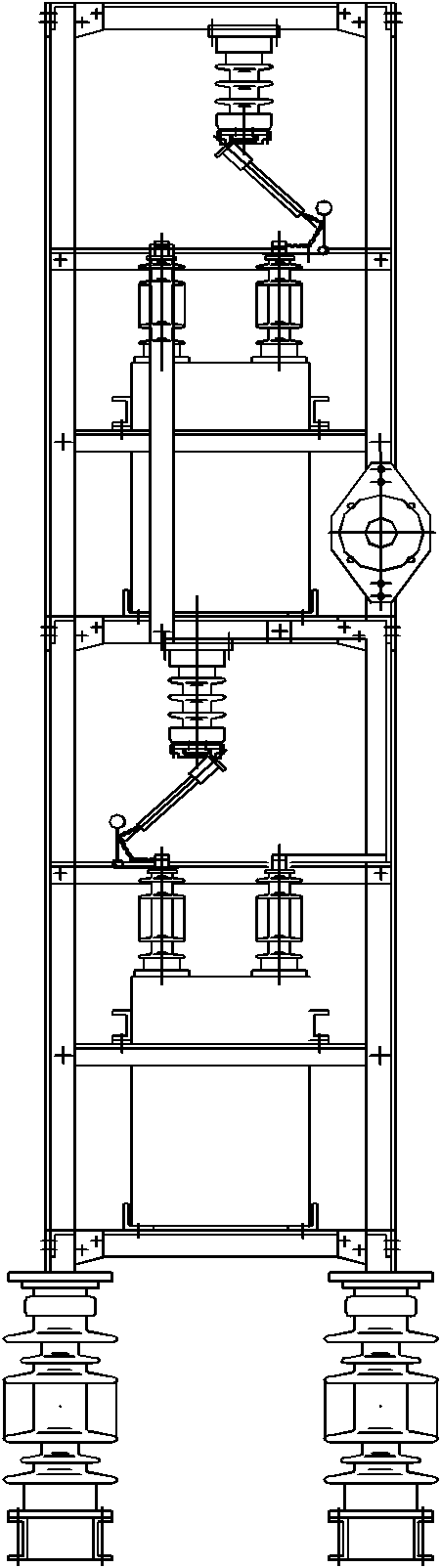

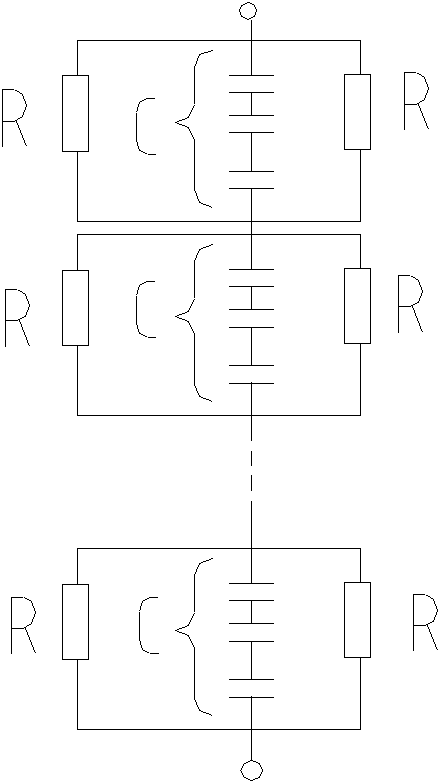

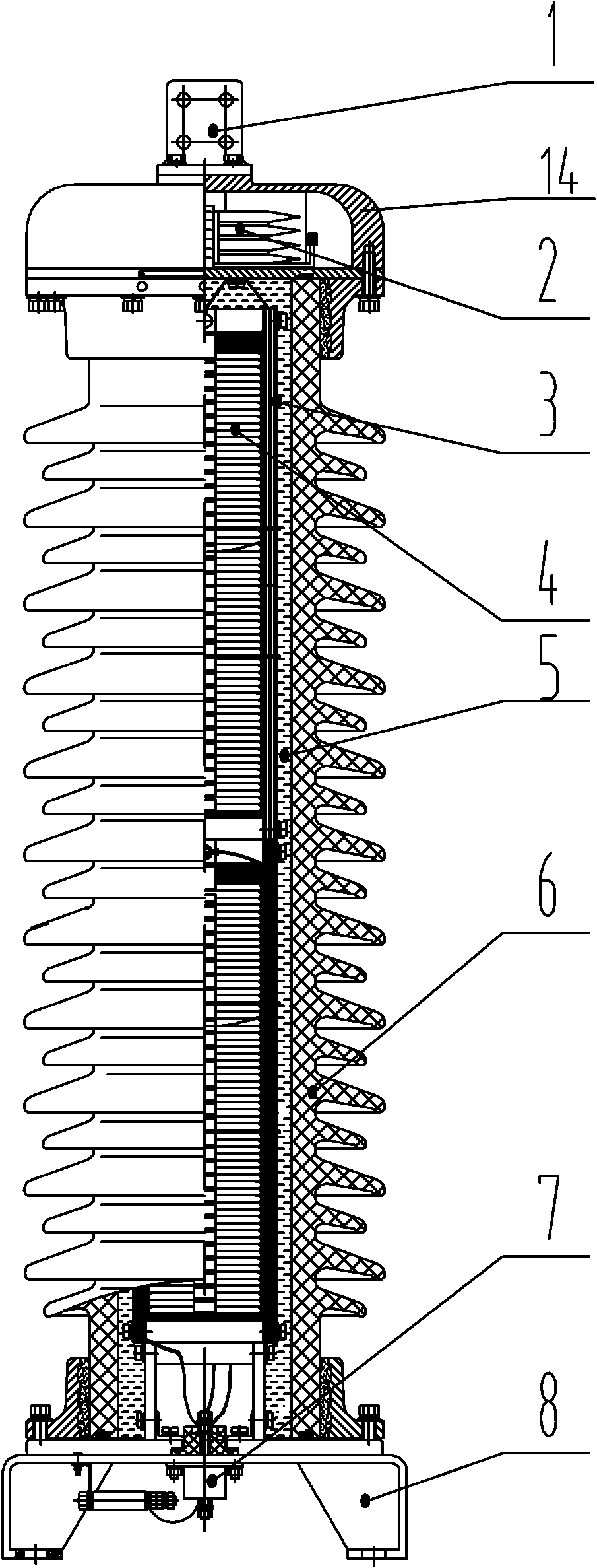

[0023] see figure 2 , this kind of ceramic sleeve type DC field PLC / RI capacitor of the present invention includes a base 8 welded by steel plates and a high voltage electric porcelain bushing 6 vertically fixed on the base 8, the high voltage electric porcelain bushing 6 is equipped There are several capacitive elements 4 immersed in the liquid insulating medium 5 and connected in series with each other, the several capacitive elements 4 in series are divided into several series sections with the same number of capacitive elements, and each series section is connected in parallel to prevent equal resistance 3. Its circuit schematic diagram is as follows figure 2 shown. In order to realize the sealing of the liquid insulating medium 5 , a sealing cover is provided on the upper end of the high voltage electric porcelain bushing 6 , and strict sealing between the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com