Photovoltaic power generation distribution type maximum power output system

A technology for maximum power output and photovoltaic power generation, applied in photovoltaic power generation, light radiation generators, photovoltaic modules, etc., can solve the problems affecting the stability and reliability of the power generation system, affecting the reliability and stability of control, output control and improving control costs and other issues, to achieve the effect of improving self-protection function, easy promotion and application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

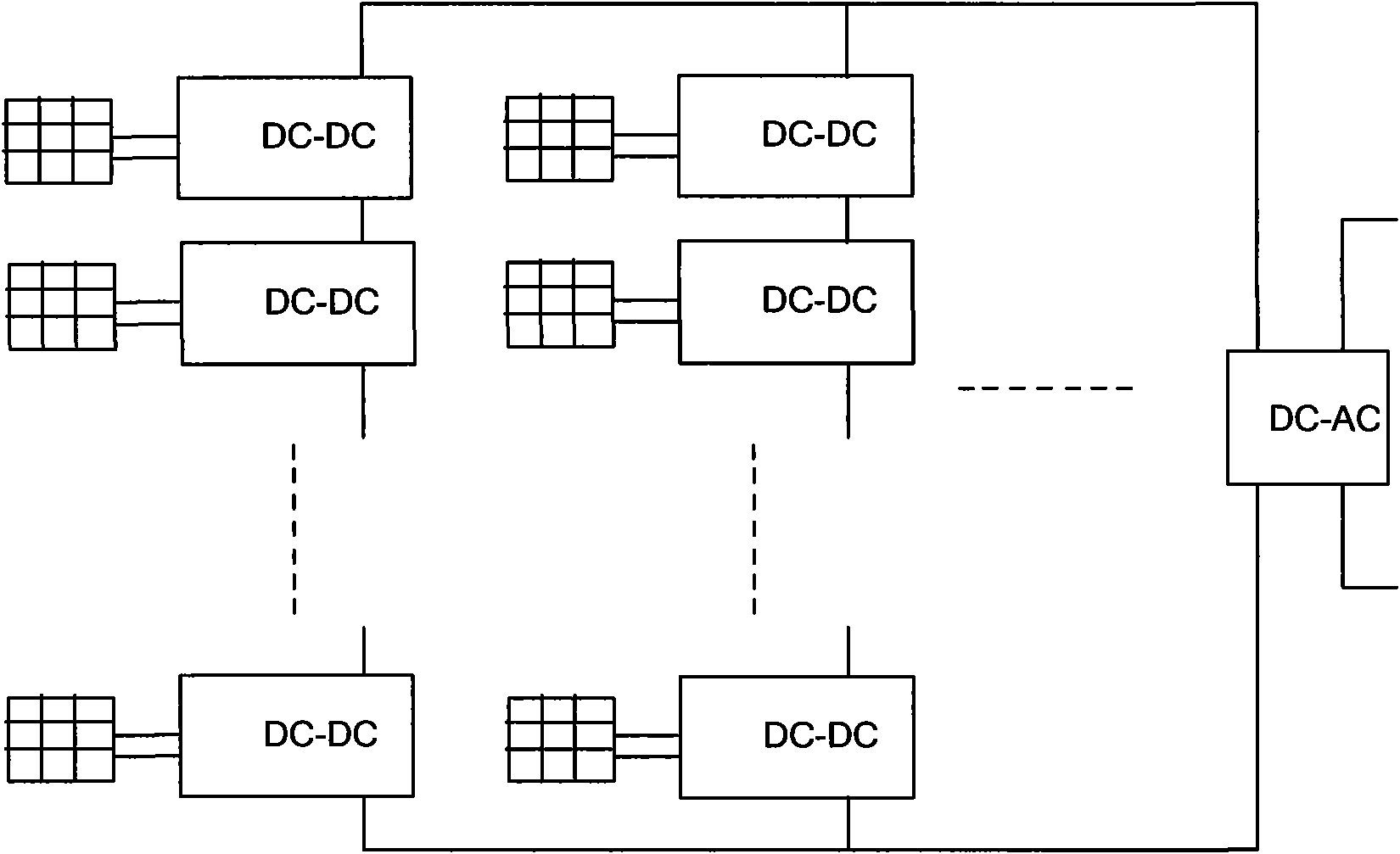

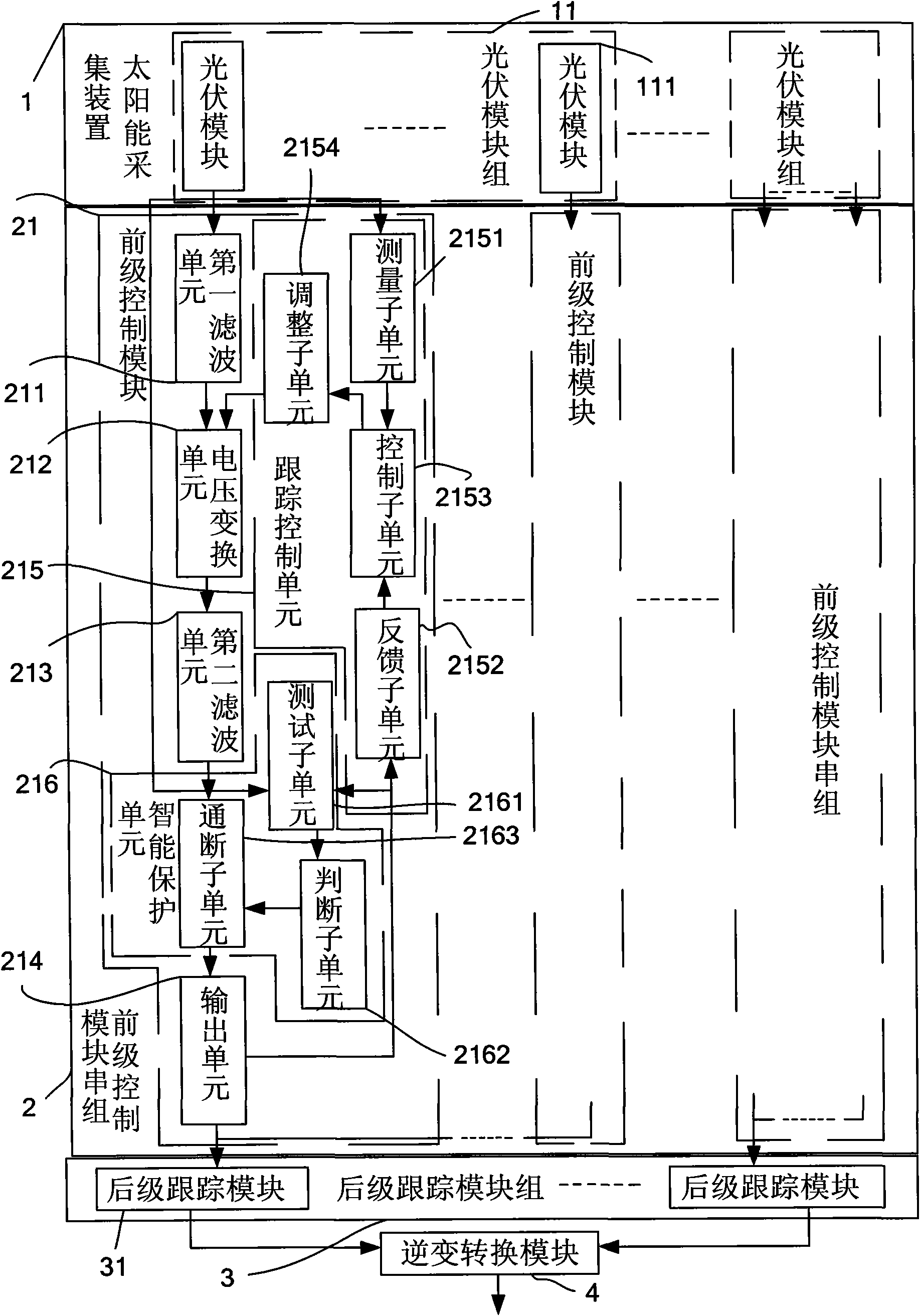

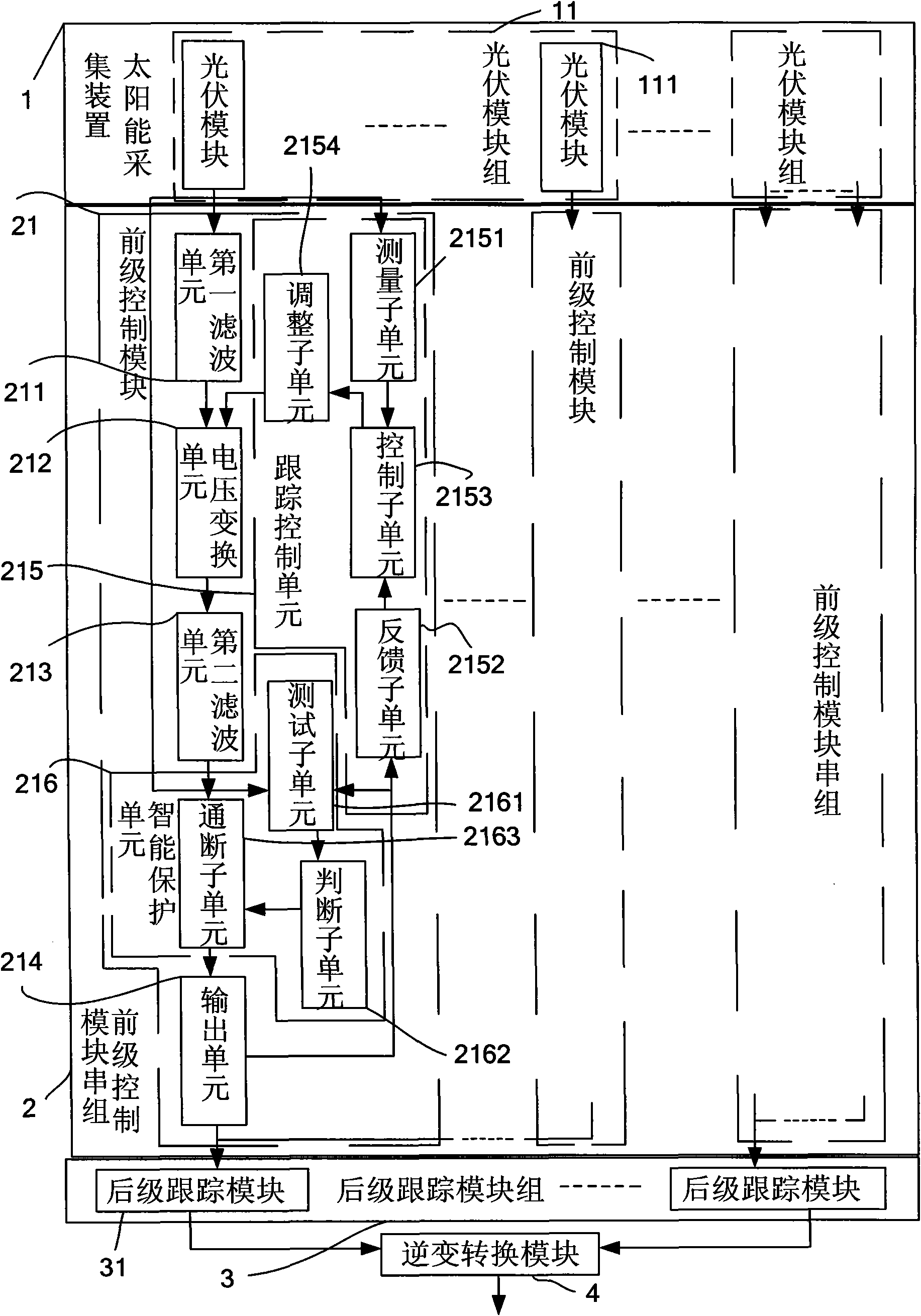

[0034] Such as figure 2 As shown, the present invention includes a solar energy collection device 1 , a front-stage control module string group 2 , a rear-stage control module group 3 and an inverter conversion module 4 . The solar energy harvesting device 1 is used to collect solar energy. It achieves the maximum power output through the two-stage control of the front-stage control module string group 2 and the rear-stage control module group 3 , and then performs current output through the inverter conversion module 4 after current conversion.

[0035] The solar energy harvesting device 1 includes more than two sets of photovoltaic module groups 11, each photovoltaic module 111 in the photovoltaic module group 11 is connected with a front-end control module 21, and the photovoltaic module 111 collects solar energy and converts the solar energy into DC power and sends it to the front-end control Module 21.

[0036] The front-end control module string group 2 includes more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com