Robot system

A robot system and robot technology, applied in the field of robot systems, can solve the problems of longer production takt time, rising air conditioning costs, and larger workshop itself, and achieve the effect of shortening production takt time, reducing air conditioning costs, and shrinking the workshop itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

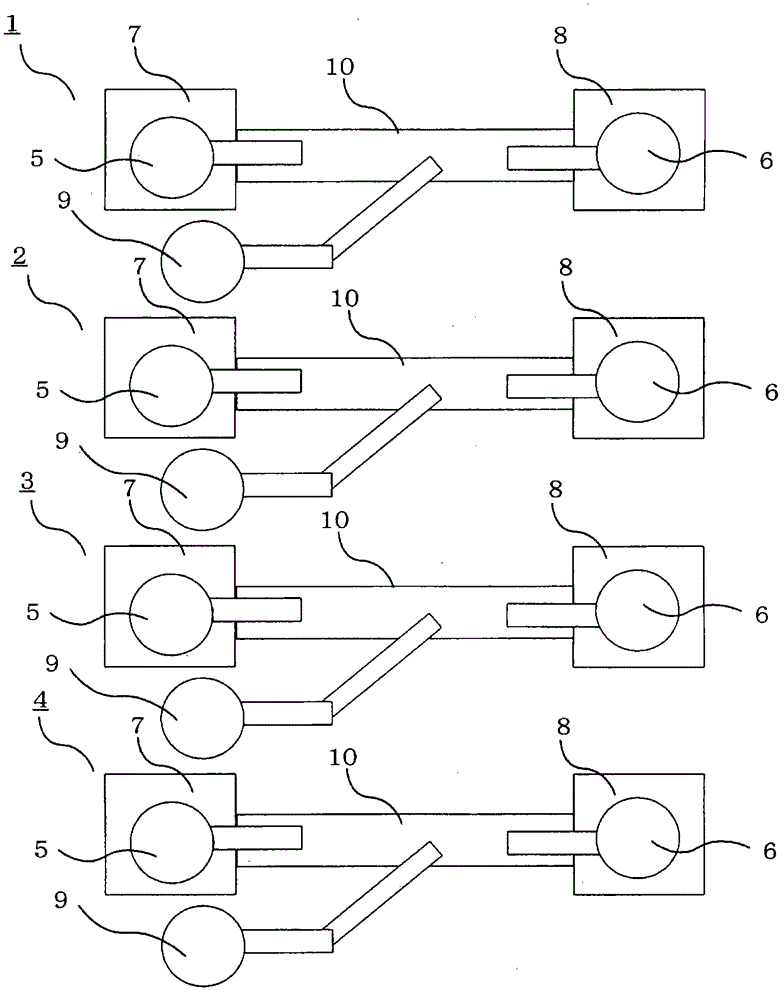

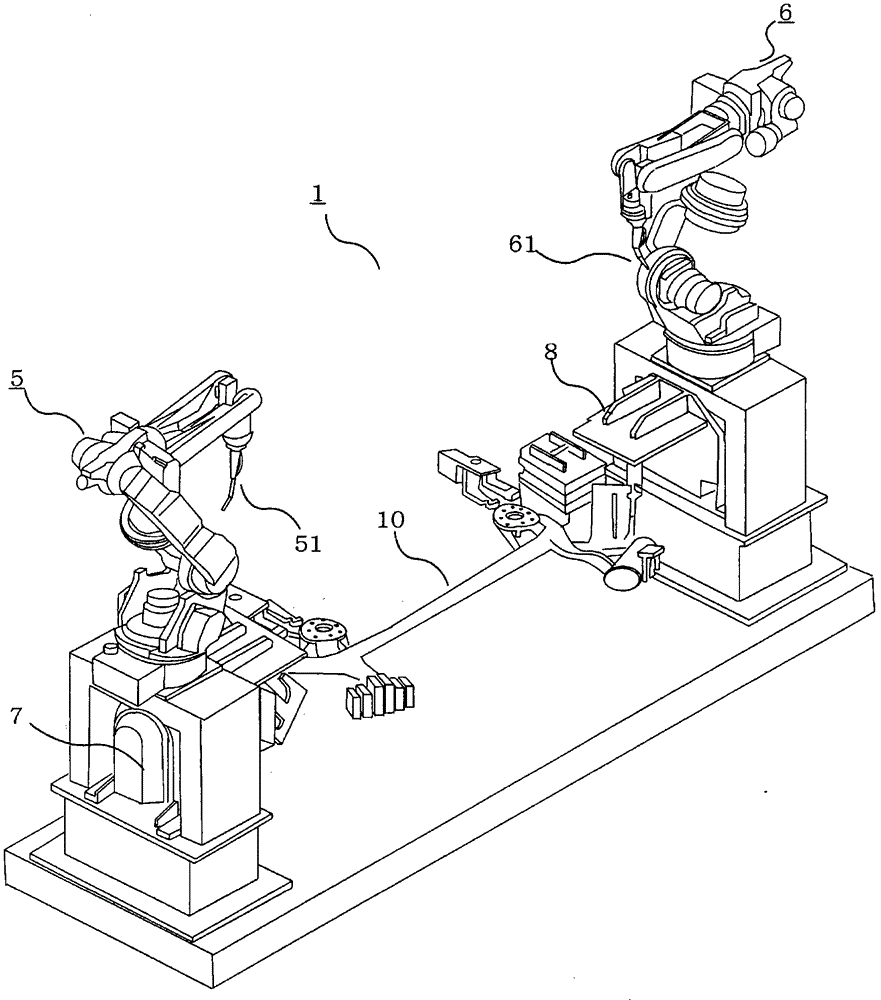

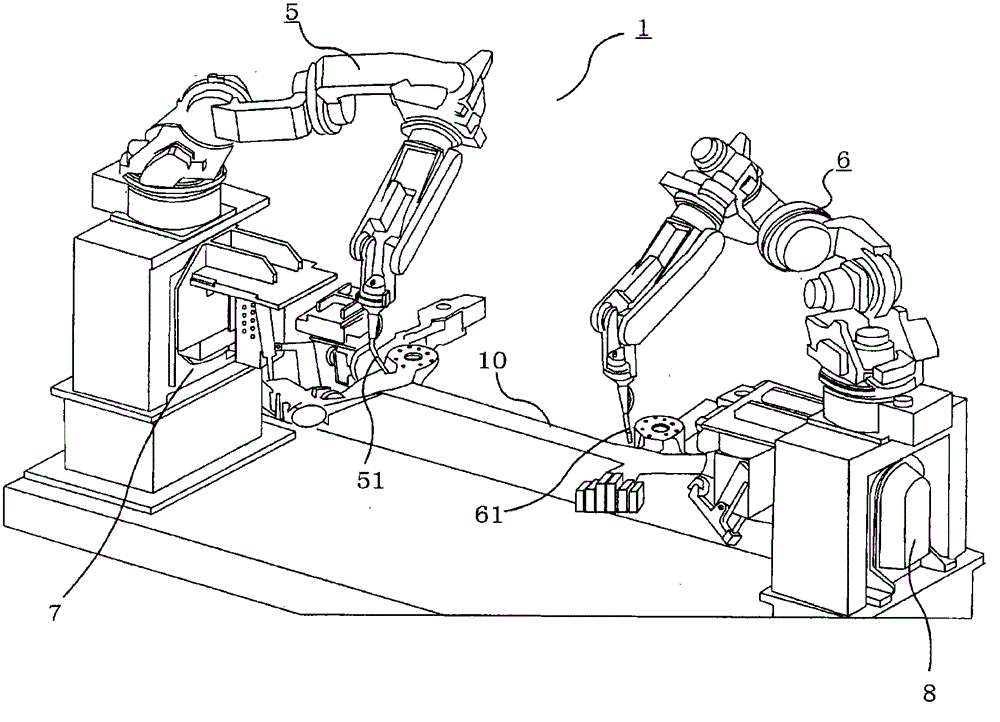

[0033] figure 1 is a plan view of the robot system of the present invention. Number 1 is the first welding process, number 2 is the second welding process, number 3 is the third welding process, number 4 is the fourth welding process, number 5 is the first welding robot, number 6 is the second welding robot, number 7 is the first positioner, the number 8 is the second positioner, the number 9 is the transfer robot, and the number 10 is the work object.

[0034] The difference between the present invention and the prior art lies in that an industrial robot is installed on a positioner and performs work on a work object.

[0035] The work object 10 is, for example, a long piece such as a chassis of a motor vehicle, and the work object 10 is attached to the first positioner 7 and the second positioner 8 in the first welding process by a transfer robot (not shown). Next, the first positioner 7 and the second positioner 8 rotate to align the welding position, and then the first w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com