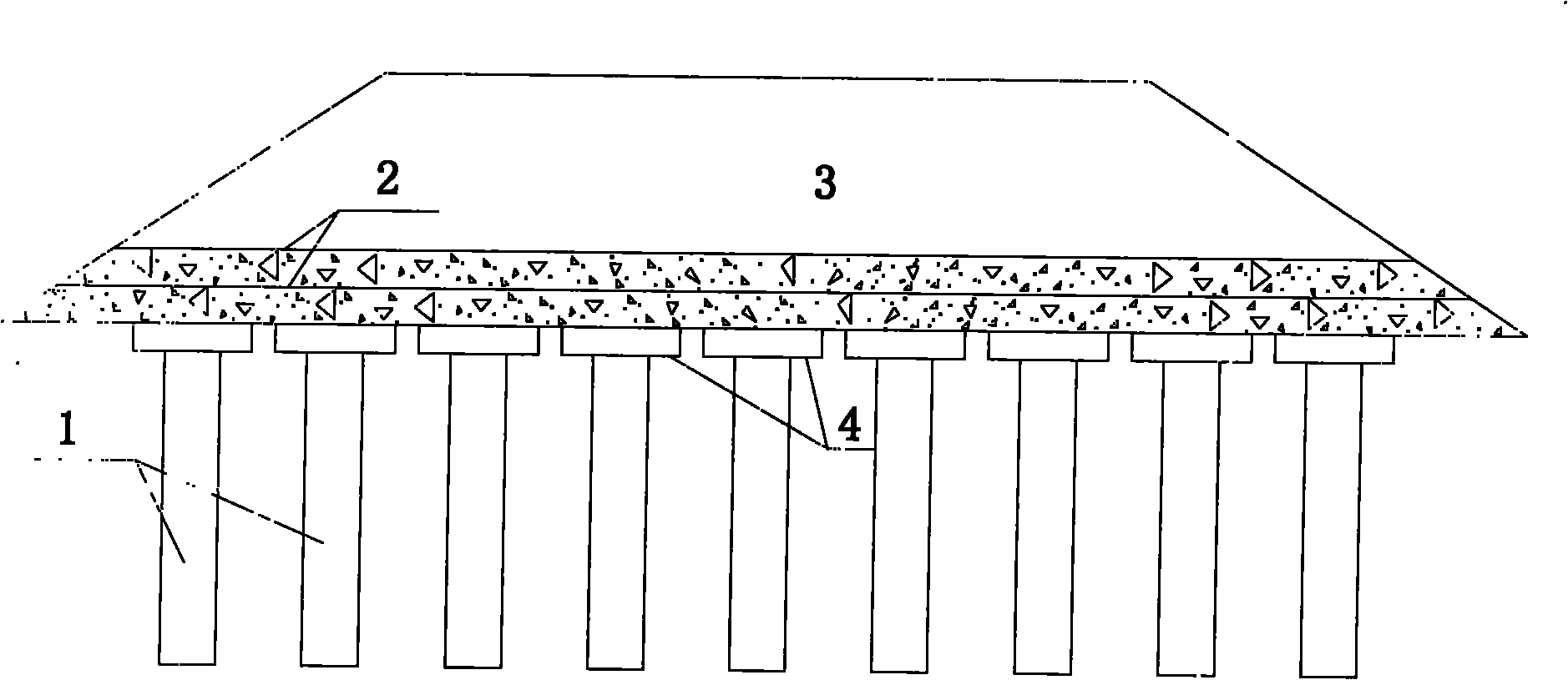

Large-diameter thin-wall cylindrical pile mesh combined structure with pile cap and construction method thereof

A technology of thin-walled cylindrical piles and composite structures, which is applied in foundation structure engineering, sheet pile walls, roads, etc., can solve problems such as single structure form, and achieve the effect of reducing settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

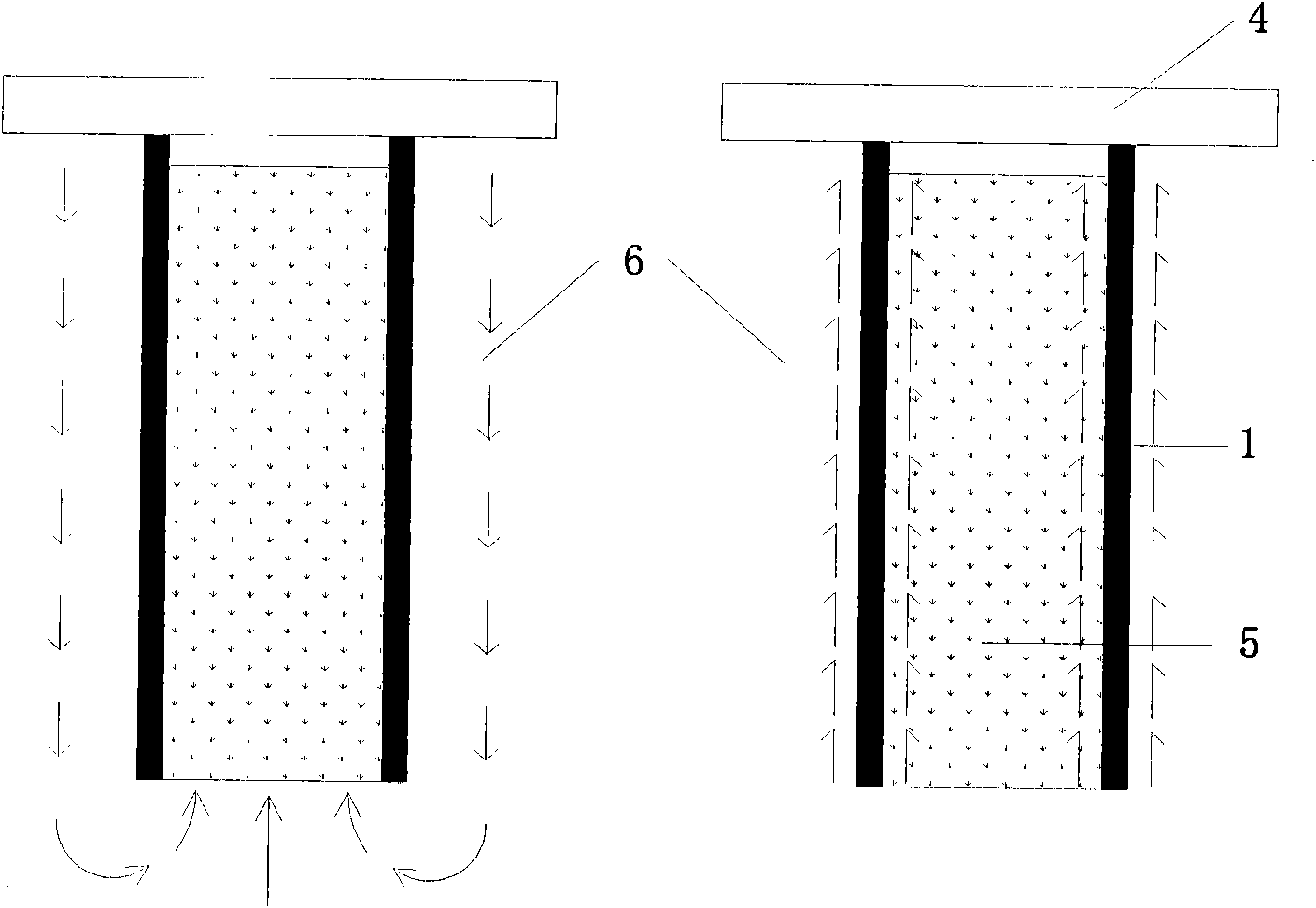

[0039] In the present invention, due to the presence of a soil core in the large-diameter thin-walled cylindrical pile body, in the case of adding a pile cap, when it is loaded and produces settlement, the pile end will penetrate into the underlying layer. The compression of the lower soil makes the soil around the pile end further squeezed into the barrel, so that the inner wall of the pile generates greater pile side friction resistance, effectively inhibiting the occurrence of settlement. Therefore, when the settlement cannot meet the requirements, it is recommended to add a pile cap on the top of the pile to make full use of the joint action of the pile and soil to enhance the ability of the pile-net composite foundation to control the settlement and deformation of the subgrade. At the same time, it is recommended to use large-scale single piles in the design Caps or multi-pile pile caps, using the characteristics of large-diameter thin-walled cylindrical pile caps to give ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com