LED illumination light source device using LED complementary color light

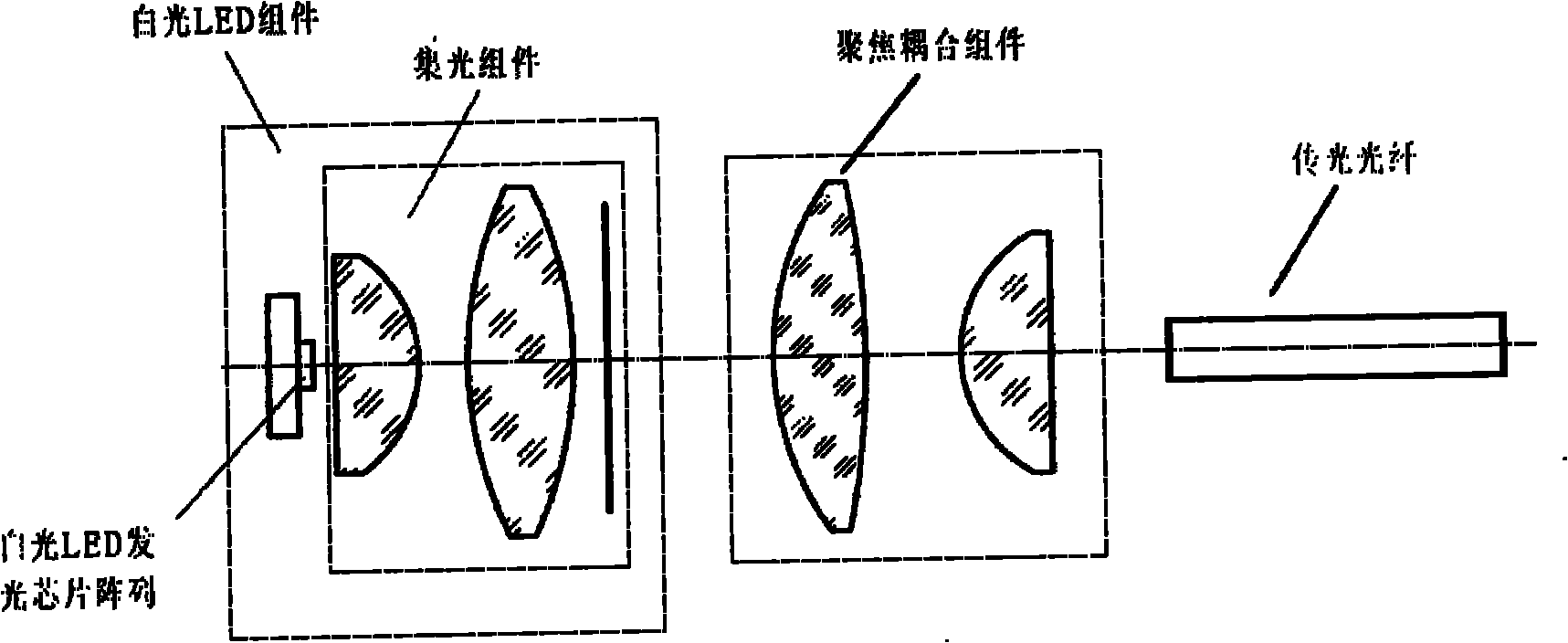

A technology of LED lighting and light source device, which is applied to lighting devices, components of lighting devices, light guides of lighting systems, etc., can solve the problems of poor reliability, poor reliability, and reduced luminous efficiency of mixed phosphor technology, so as to avoid low luminescence Efficiency issues, high reliability, high efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

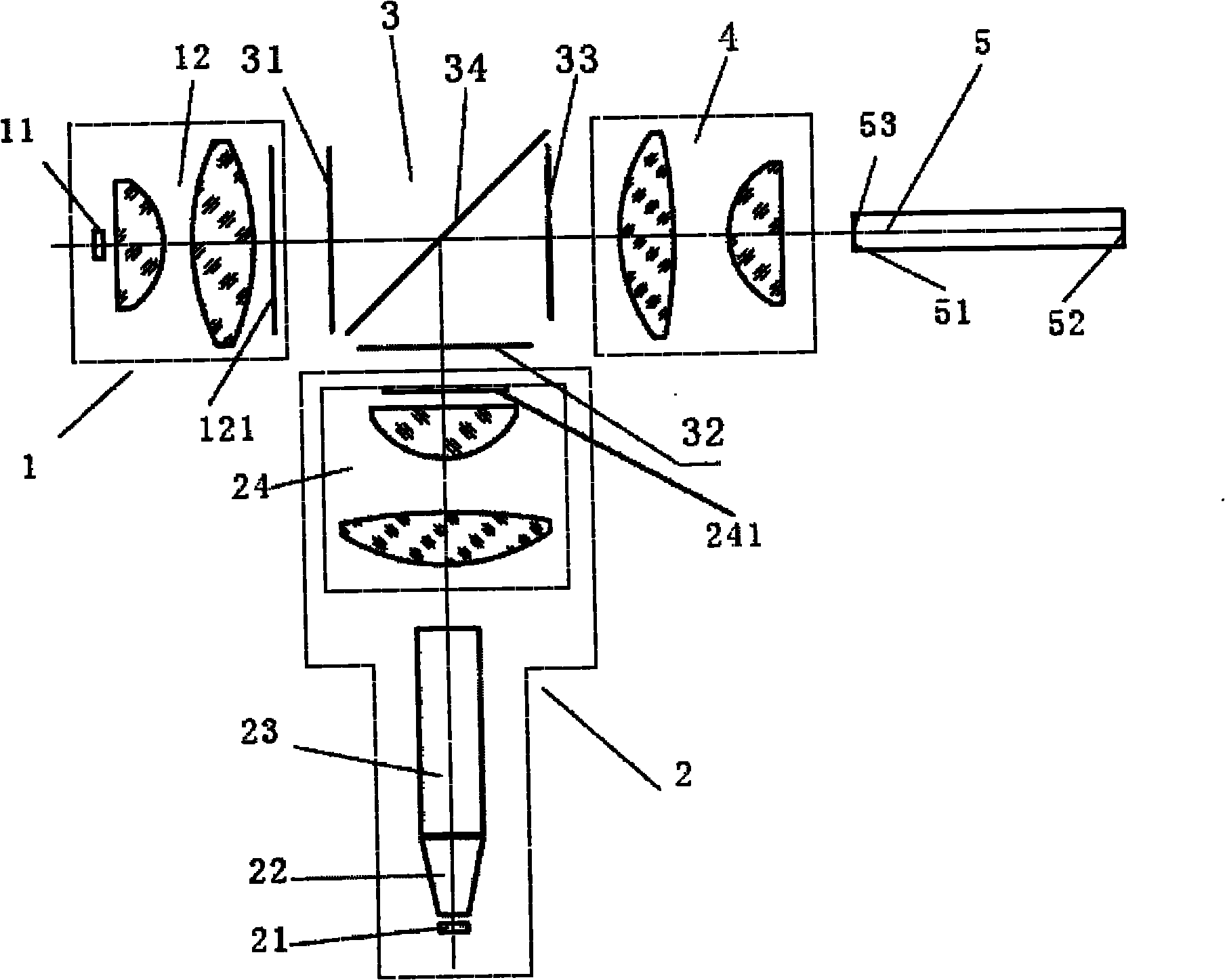

[0022] In this embodiment, except that the color combiner 3 is a glued prism, the remaining parts have the same figure 2 The structure shown is exactly the same, the following is its key technical data:

[0023] The white LED light-emitting chip array 11 includes nine white LED light-emitting chips, which are arranged in a 3×3 matrix. The size of each white LED light-emitting chip is 1mm×1mm, and the distance between adjacent chips is 0.1mm. The white light collection optics Component 12 is a lens group, and the focal length of the lens group is 12mm;

[0024] Complementary color LED light-emitting chip array 21 includes four complementary color LED light-emitting chips, arranged in a 2×2 matrix, of which there are two blue light LED light-emitting chips, two red light LED light-emitting chips, and each complementary color LED light-emitting chip The size is 1mm×1mm, and the distance between adjacent chips is 0.1mm. The green LED light emitting chips and the red light LED li...

Embodiment 2

[0035] This embodiment has the same figure 2 The structure shown is exactly the same, the following is its key technical data:

[0036] The color combiner 3 is a plane color combiner with a size of 28mm×40mm×1mm. In addition, the rest of the technical data are exactly the same as those of the first embodiment.

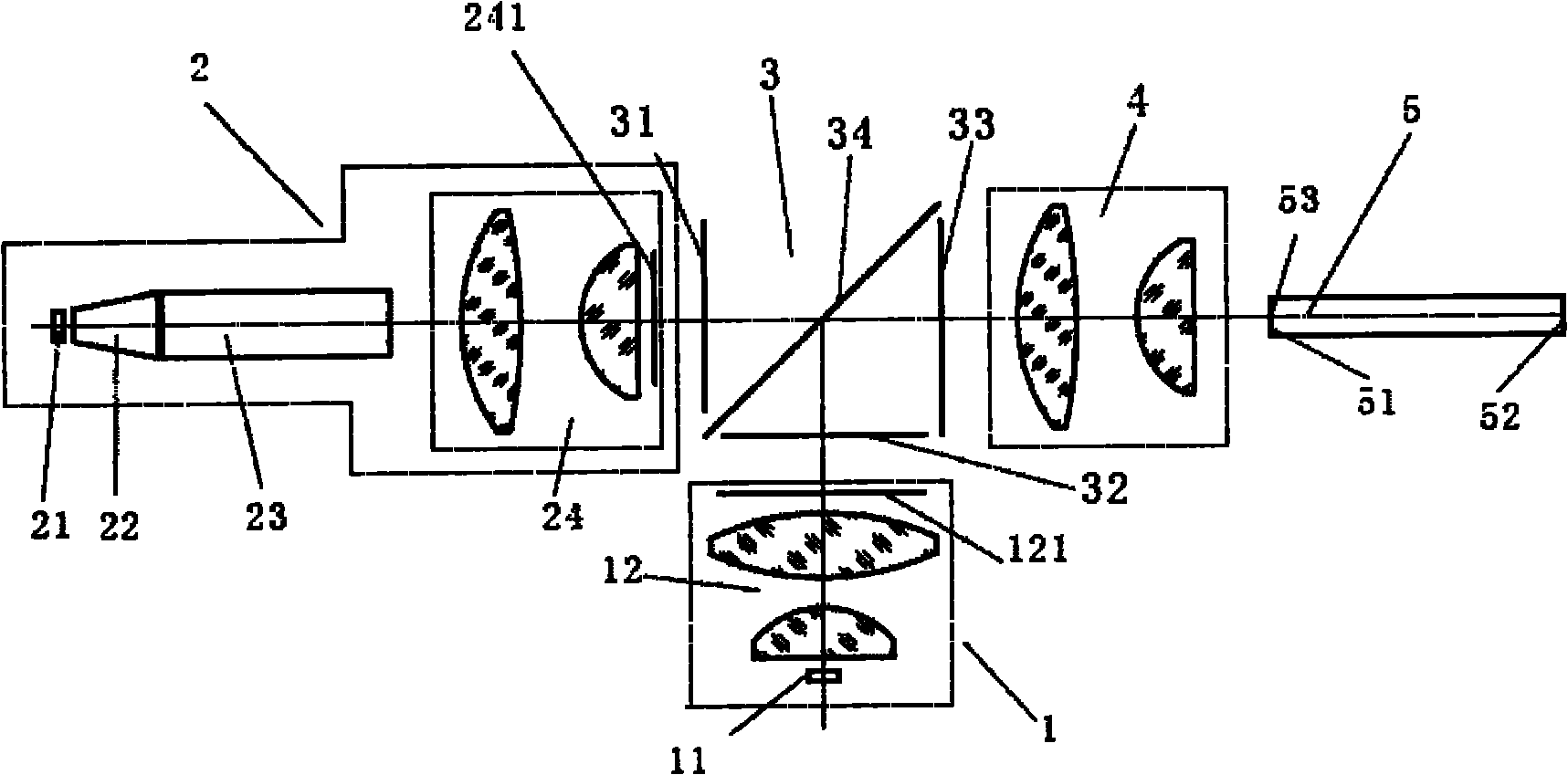

Embodiment 3

[0038] This embodiment has the same image 3 The structure shown is exactly the same, the following is its key technical data:

[0039] The white LED light-emitting chip array 11 includes nine white LED light-emitting chips, which are arranged in a 3×3 matrix. The size of each white LED light-emitting chip is 1mm×1mm, and the distance between adjacent chips is 0.1mm. The white light collection optics Component 12 is a lens group, and the focal length of the lens group is 12mm;

[0040] Complementary color LED light-emitting chip array 21 includes four complementary color LED light-emitting chips, arranged in a 2×2 matrix, of which there are two blue light LED light-emitting chips, two red light LED light-emitting chips, and each complementary color LED light-emitting chip The size is 1mm×1mm, and the distance between adjacent chips is 0.1mm. The green LED light emitting chips and the red light LED light emitting chips are arranged in different rows and different columns in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com