Reflector structure

A reflector and fixing mechanism technology, applied in the field of communication, can solve problems such as cost increase, and achieve the effects of improving return loss, reducing manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

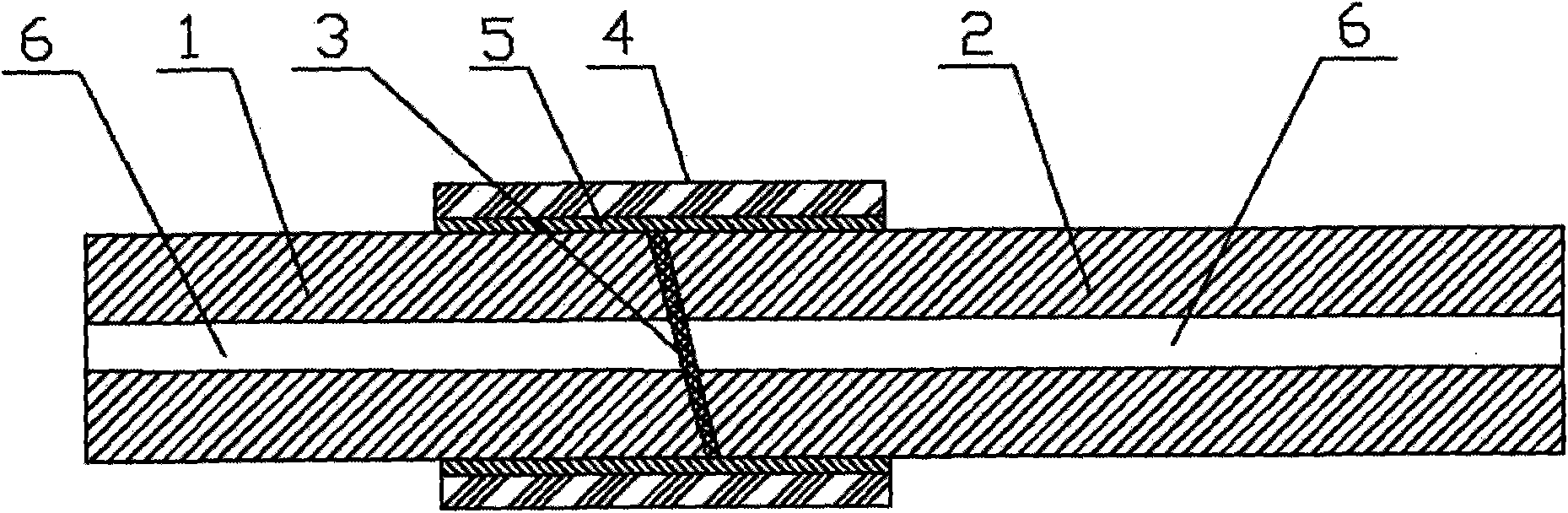

[0020] The first embodiment of the present invention proposes a reflector structure, including: a first ferrule 1 with an optical fiber 6 inside, a second ferrule 2 with an optical fiber 6 inside, the first ferrule 1 and the The second ferrule conducts 2; if figure 1 , figure 2 As shown, one end of the first ferrule 1 and the second ferrule 2 is a corresponding slope; and the slope of the first ferrule 1 and the second ferrule 2 is provided There is an inclined filter mechanism; and the first ferrule 1 and the second ferrule 2 are aligned and fixed by the fixing mechanism 4 .

[0021] Wherein, the filter mechanism is used to reflect light of some wavelengths and transmit light of some wavelengths.

[0022] In the embodiment of the present invention, an inclined filter film is arranged between the first ferrule and the second ferrule, so that the return loss of service light can be improved. The filter film can realize the reflection of some wavelengths of light and the tra...

Embodiment 2

[0024] The first embodiment of the present invention proposes a reflector structure, including: a first ferrule 1 with an optical fiber 6 inside, a second ferrule 2 with an optical fiber 6 inside, the first ferrule 1 and the first ferrule 1 Two ferrule conduction 2; figure 1 , figure 2 As shown, one end of the first ferrule 1 and the second ferrule 2 is a corresponding slope; and the slope of the first ferrule 1 and the second ferrule 2 is provided There is an inclined filter mechanism 3 . Further, as image 3 As shown, a fixing mechanism 4 can also be provided to fix the first ferrule 1 and the second ferrule 2 so that the first ferrule 1 and the second ferrule 2 are aligned. Adhesives or matching fluids or air can also be provided to improve the reflective properties. Wherein, the adhesive can be: XOC, NORLAND81.

[0025] Among them, such as figure 1 , figure 2 As shown, the reflective structure is a filter film 3 . At the same time, if image 3 , Figure 4 As sh...

Embodiment 3

[0032] The third embodiment of the present invention proposes a method for manufacturing the reflector structure of the aforementioned first embodiment and the second embodiment, the process of which is as follows Figure 5 shown, including:

[0033] Step 101, forming a first inclined plane at one end of the first ferrule, forming a second inclined plane at the corresponding end of the second ferrule; and making the first inclined plane correspond to the inclination angle of the second inclined plane;

[0034] Step 102, forming a filter film on the first slope, the filter film closing the end of the first ferrule;

[0035] Step 103 , connecting the first slope of the first ferrule with the second slope of the second ferrule, so that the first ferrule and the second ferrule form a mutually conducting and sealed channel.

[0036] The method of the embodiment of the present invention can easily manufacture the reflector structures of the aforementioned first embodiment and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com