Independent digital flame following and heating device of hot spinning machine

A flame heating and hot spinning technology, applied in the field of hot spinning workpiece heating device, can solve the problems of easy burning equipment, uneven temperature field of workpiece, unable to meet tolerance requirements, etc., to avoid equipment wear, solve the need for protection, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

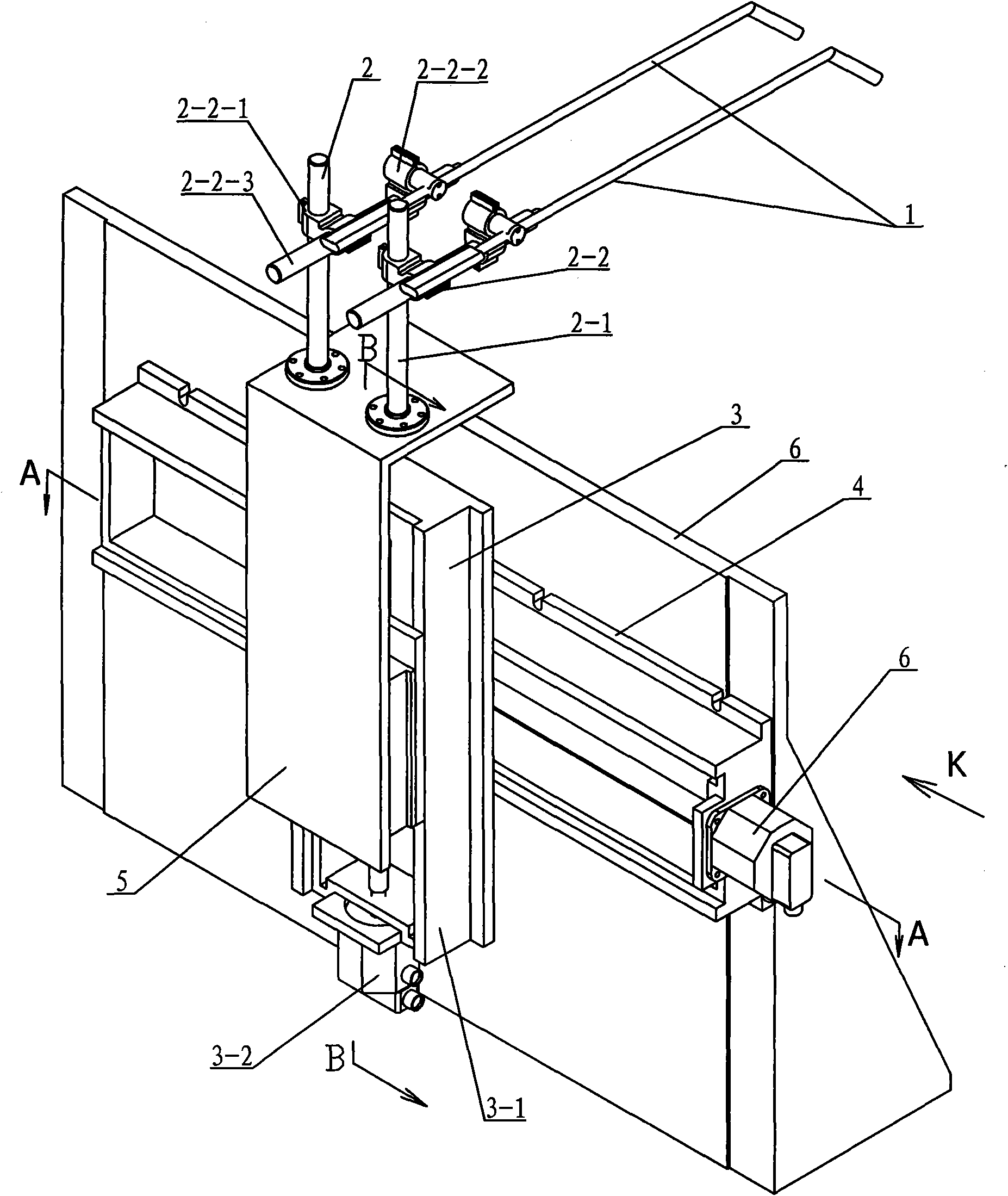

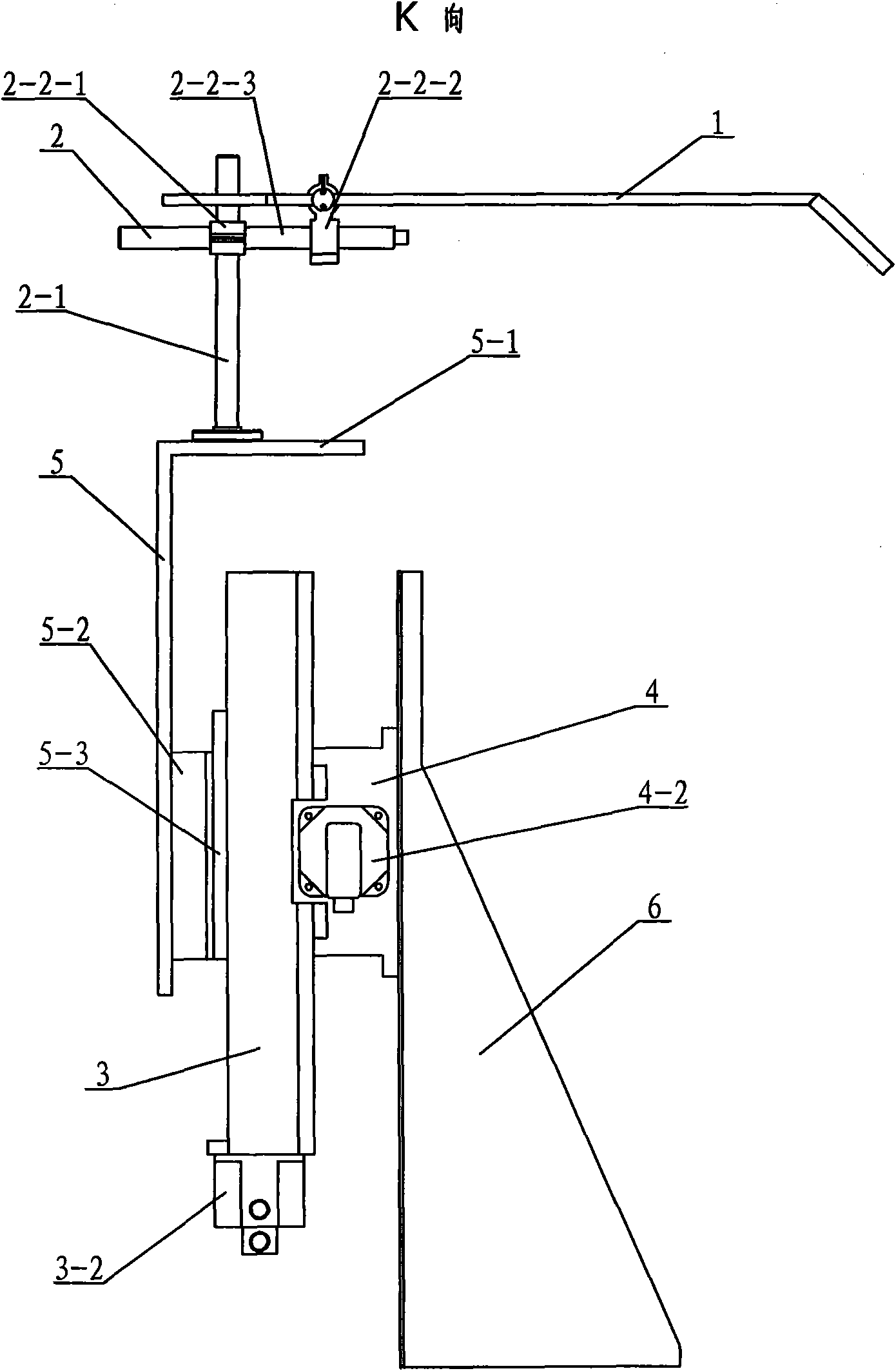

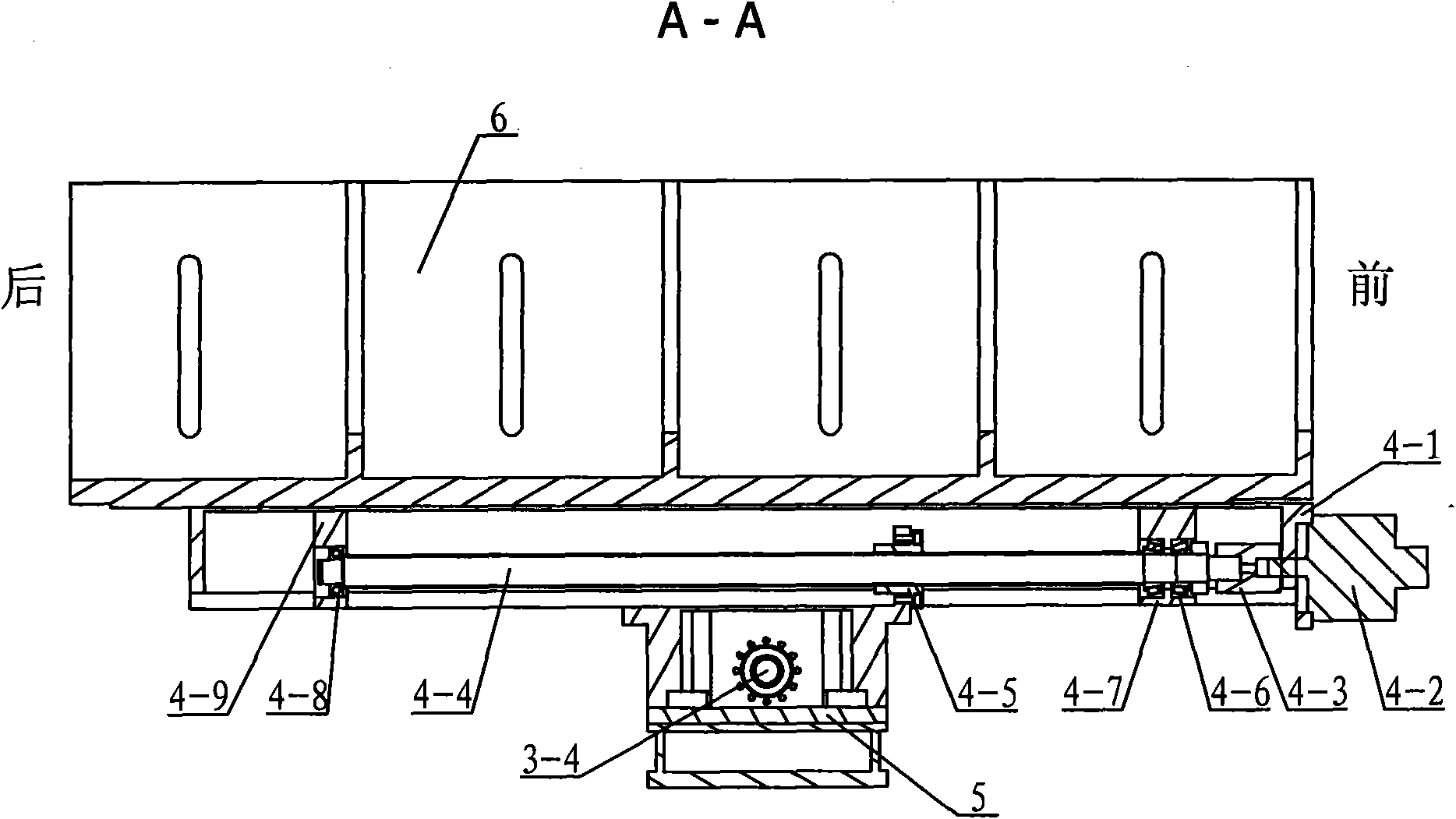

[0008] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, this embodiment includes a vertical sliding mechanism 3, a longitudinal sliding mechanism 4, an adjustment frame 5, a fixed seat 6, two torches 1 and two adjustment mechanisms 2, and the longitudinal sliding mechanism 4 is composed of a housing 4-1 , longitudinal servo motor 4-2, longitudinal coupling 4-3, longitudinal ball screw 4-4, longitudinal nut 4-5, front support bearing 4-6, front bearing housing 4-7, rear support bearing 4- 8 and the rear bearing seat 4-9, the front bearing seat 4-7 and the rear bearing seat 4-9 are respectively fixed at the front end and the rear end of the housing 4-1, and the front support bearing 4-6 is installed on the front bearing seat In 4-7, the rear support bearing 4-8 is installed in the rear bearing seat 4-9, and the two ends of the longitudinal ball screw 4-4 are respectively arranged in the inner holes of the front support bearing 4-6 and the...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, each adjustment frame 2-2 of this embodiment is made up of first universal joint 2-2-1, second universal joint 2-2-2 and connecting rod 2-2-3, and connecting rod One end of the 2-2-3 is connected with the first universal joint 2-2-1, and the other end of the connecting rod 2-2-3 is connected with the second universal joint 2-2-2. This design can make the torch 1 be adjusted in any direction. Other components and connections are the same as those in the first embodiment.

[0011] Working principle of the present invention: when the longitudinal servo motor 4-2 rotates, it drives the longitudinal ball screw 4-4 to rotate, and the vertical sliding mechanism 3 is driven along the axis of the longitudinal ball screw 4-4 through the longitudinal nut 4-5 Direction movement, so as to convert the rotary motion into longitudinal linear motion; when the vertical servo motor 3-2 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com