Pressure detection device and microbial detection film system

A technology for microbial inspection and pressure detection, applied in enzymology/microbiology devices, methods for supporting/immobilizing microorganisms, post-processing of biomass, etc., can solve problems that affect the accuracy of inspection, lack of storage equipment, and pressure rise, etc., to achieve Avoid the bursting of the tank, ensure the correctness, and the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

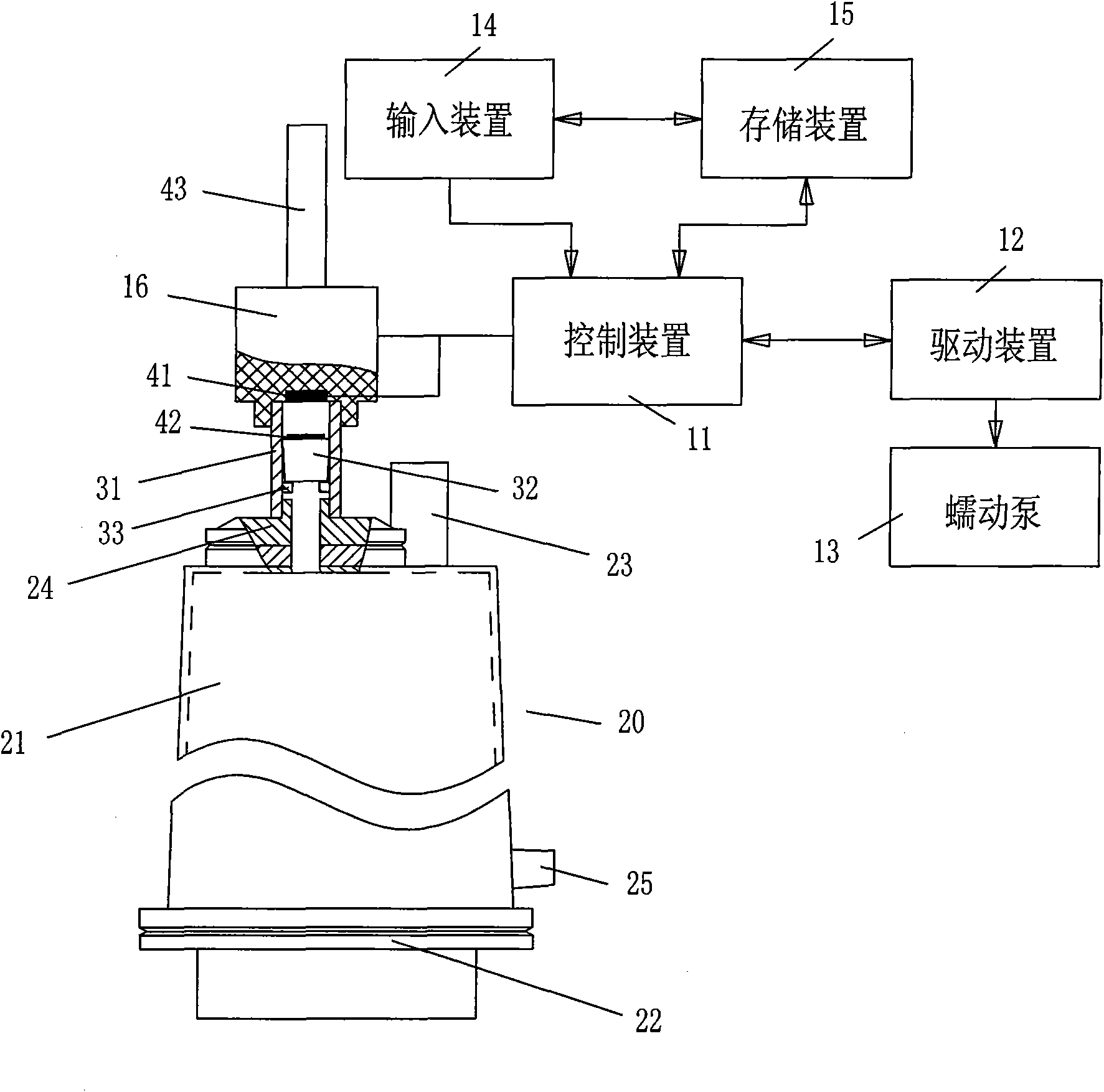

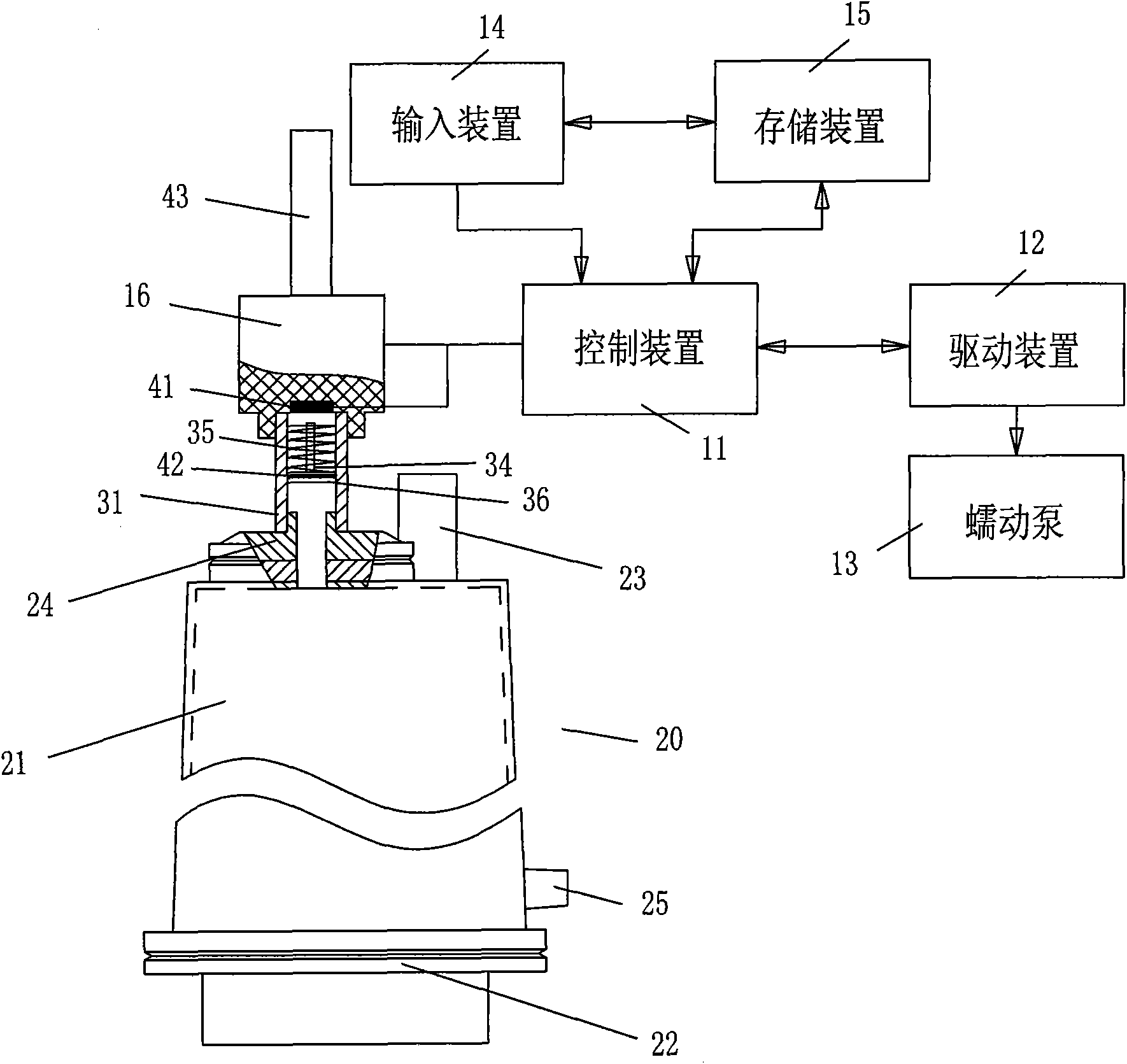

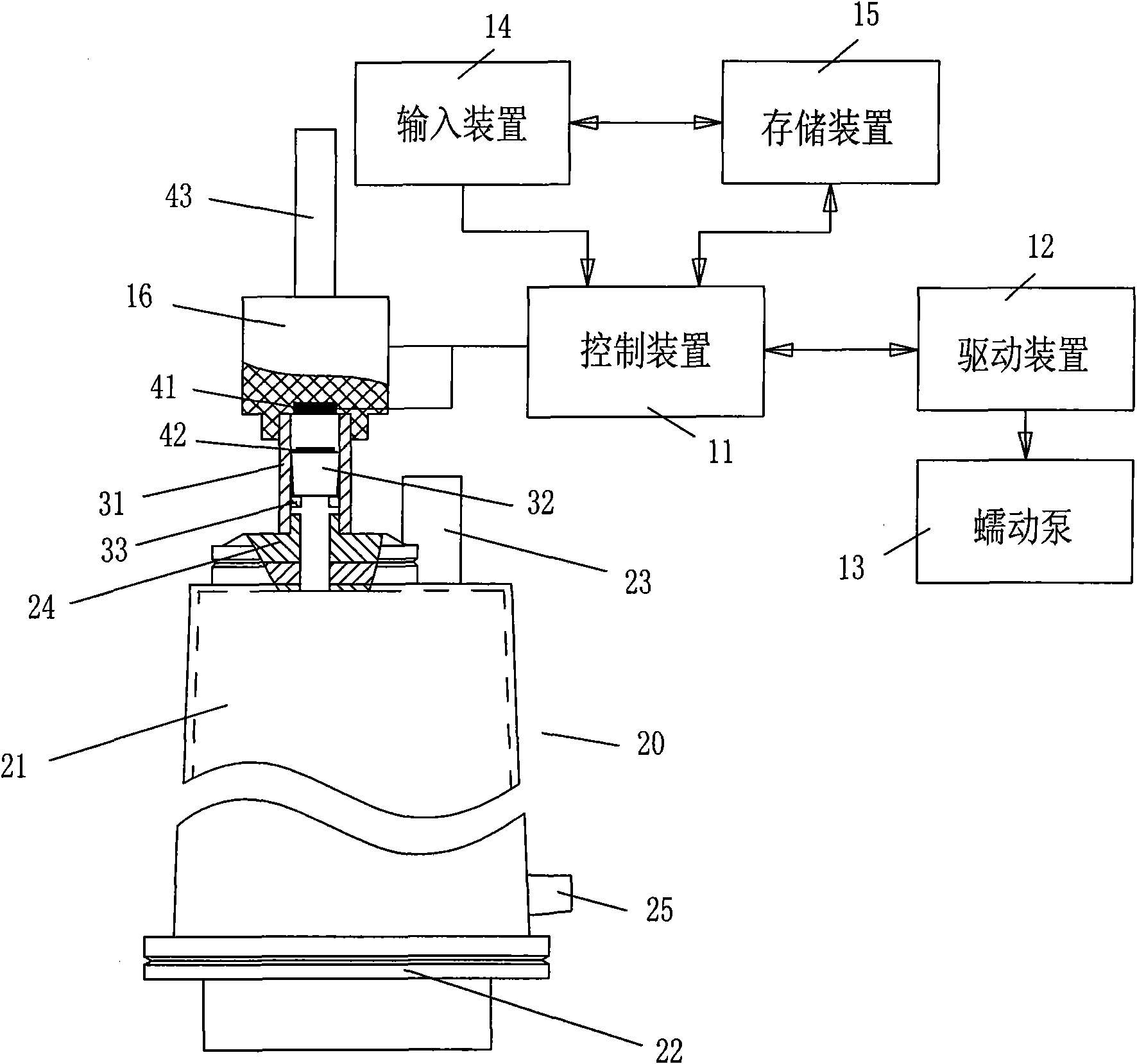

[0014] like figure 1 and figure 2 As shown, the microbiological inspection membrane system of the present invention includes a microbiological inspection membrane filter driver and a fully enclosed sterile test filter incubator. The microbial inspection membrane filter driver includes a control device 11 and an input device 14. The signal output terminal of the input device 14 It is connected with the corresponding signal end on the control device 11, and the peristaltic pump 13 is connected with the corresponding signal end on the control device 11 through the driving device 12. The fully enclosed sterile test filter culture device includes a delivery hose (not shown in the figure ) and a filter 20, the filter 20 is placed on the tank frame (not shown), the filter 20 includes a tank 21 with an open bottom, the bottom of the tank 21 is provided with a base 22, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com