Gear pump

A gear pump, driven gear technology, applied in the direction of pressure lubrication of pumps, rotary piston pumps, lubricating pumps, etc., can solve the problems of gear pump oil pressure pulsation, etc., to reduce oil pressure pulsation, reduce fuel consumption, and improve power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

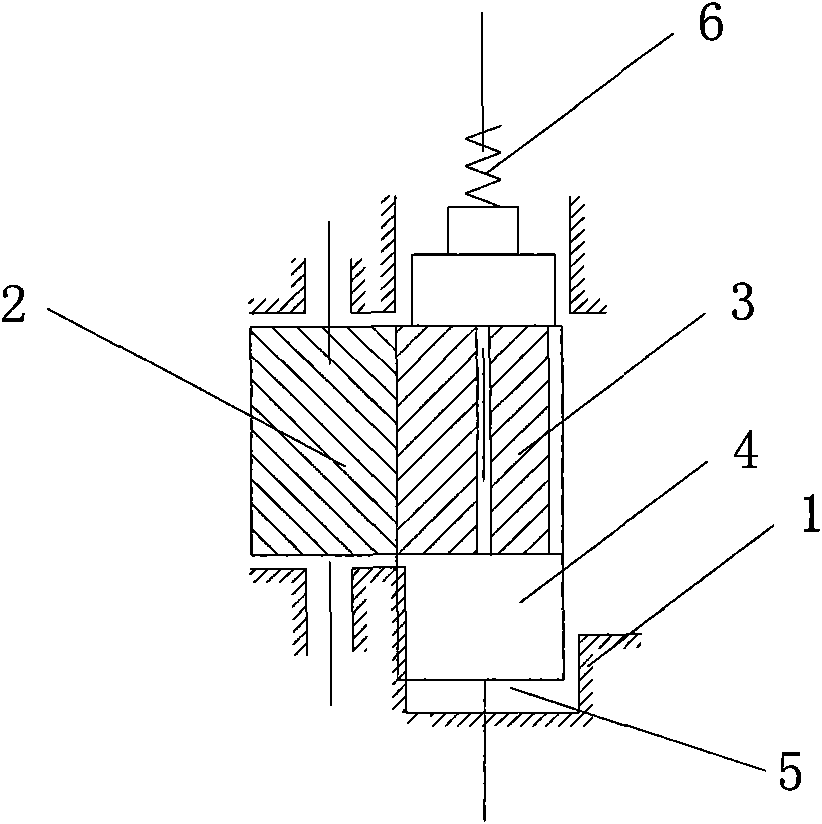

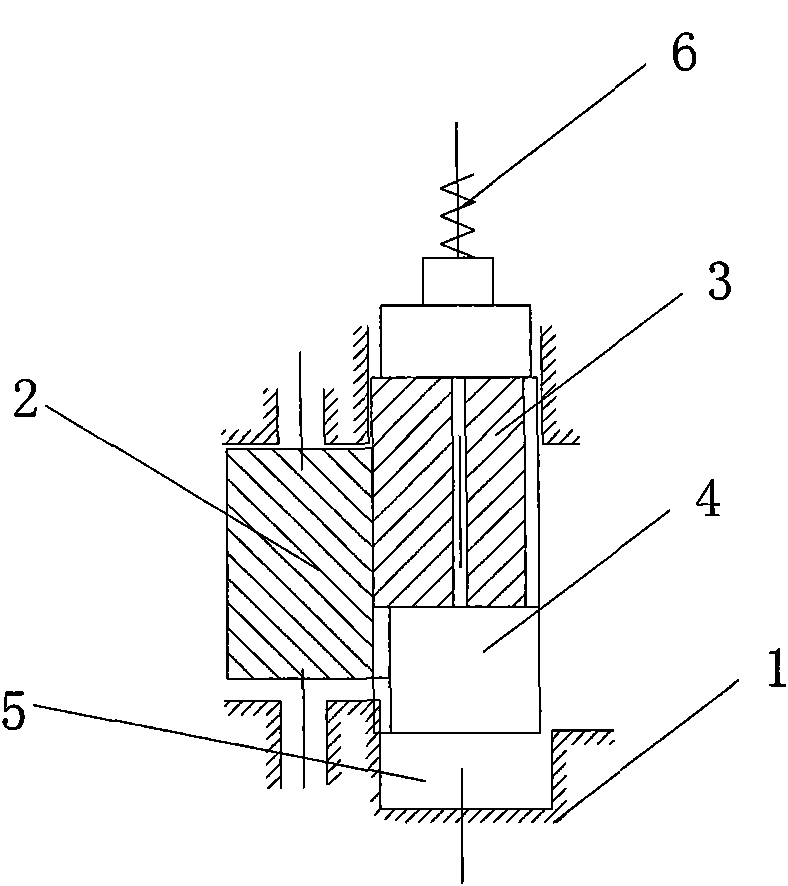

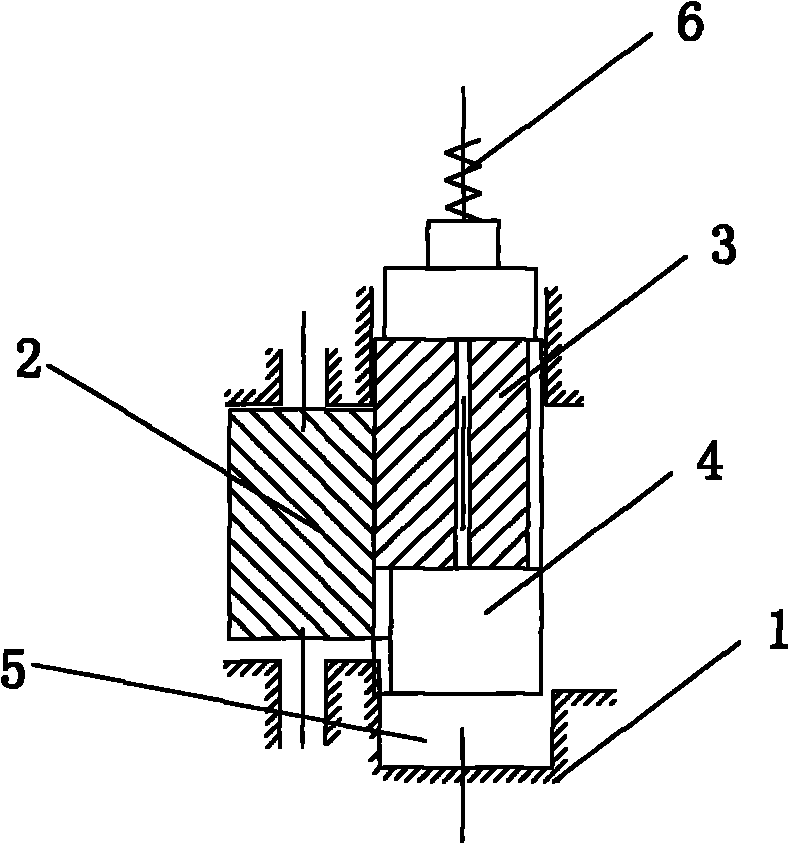

[0018] Example 1, such as figure 1 , 2 As shown, a gear pump includes a pair of meshing driving gear 2 and driven gear 3 in a housing 1; the housing 1 has an oil inlet and an oil outlet. One end of the driven gear 3 is also provided with a piston 4 and a control hydraulic cylinder 5 to promote its axial reciprocating movement, and the other end of the driven gear is also provided with a reset compression spring 6 for adjusting the pressure of the oil outlet. Described driving gear, driven gear are spur gears. The control oil pressure cylinder is connected and controlled by the pressure feedback signal from the main oil passage of the engine.

Embodiment 2

[0019] Embodiment 2, a gear pump, which includes a pair of meshing driving gears and driven gears in a housing; the housing has an oil inlet and an oil outlet. One end of the driven gear is also provided with a reciprocating electric actuator, which has a worm gear structure, and one end of the worm is connected to the driven gear.

Embodiment 4

[0020] Embodiment 4, a gear pump, which includes a pair of meshing driving gears and driven gears in a housing; the housing has an oil inlet and an oil outlet. One end of the driven gear is also provided with the reciprocating electric actuator, which has a screw structure, and one end of the screw is connected to the driven gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com