Precise temperature control system with all-weather wide temperature zone

A temperature control system, all-weather technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of poor economy and reliability, and achieve automatic operation, wide temperature control range, flexible and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

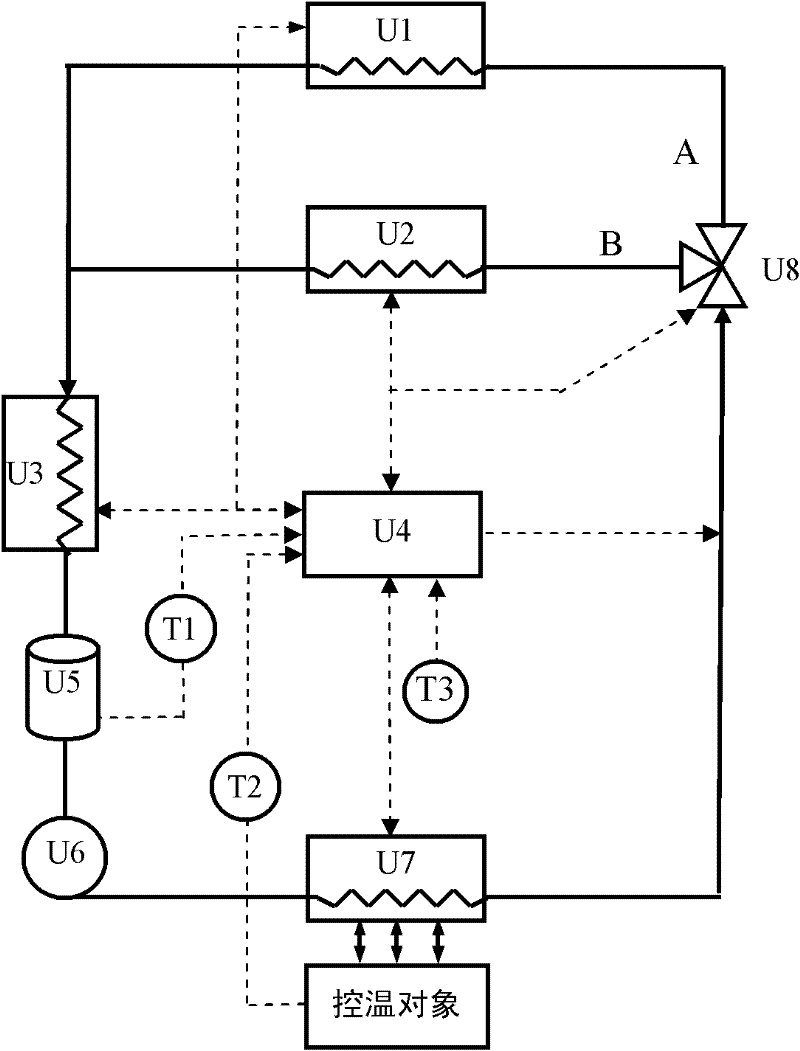

[0031] see figure 1 , the system composition of the all-weather wide temperature zone precision temperature control system in this embodiment is:

[0032] The cold and heat source system is composed of the mechanical refrigeration unit U1, the air-cooled cooling unit U2 and the electric heating unit U3.

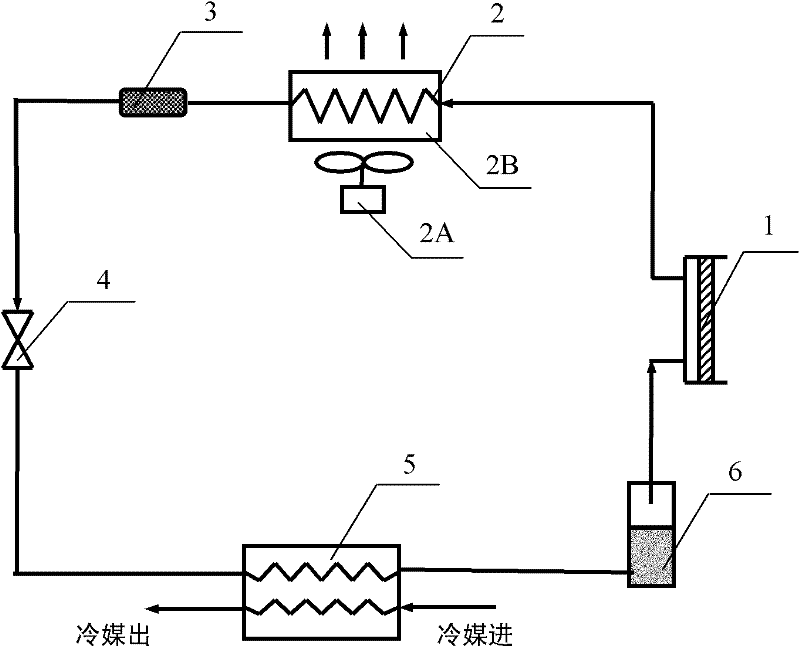

[0033] Set the forced closed refrigerant cycle driven by the liquid pump U6: In the refrigerant circuit, the refrigerant in the accumulator U5 passes through the liquid pump U6, the heat sink U7 and the three-way valve U8 in turn, and then flows through the outlet port of the three-way valve U8. One of the two parallel branches returns to the liquid receiver U5 through the electrothermal module U3 in the main circuit. One of the two parallel branches is the mechanical refrigeration unit U1 through the outlet A of the three-way valve, and the other is through the three-way valve. The air-cooled cooling unit U2 at outlet B; among them, the electric heating unit U3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com