P-type silicon-on-insulator transverse device for improving current density and preparation process thereof

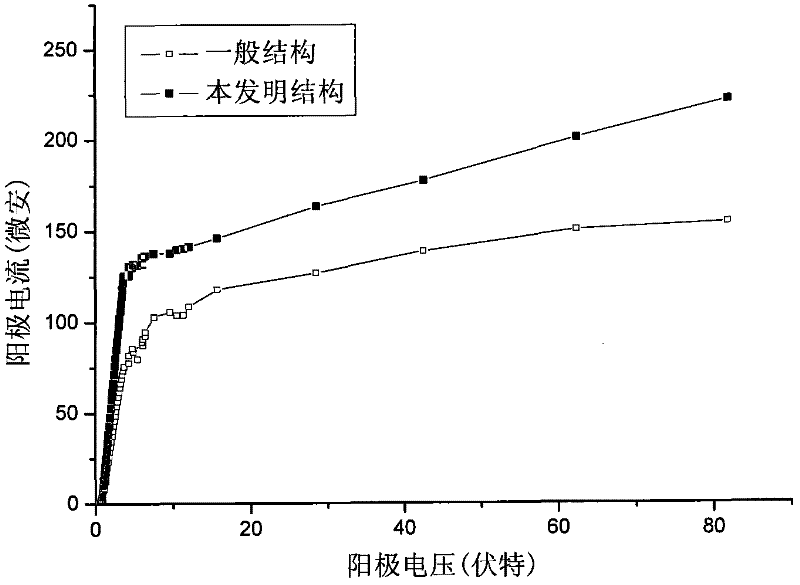

A technology of silicon-on-insulator and lateral devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of saving production costs, increasing device current, and increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

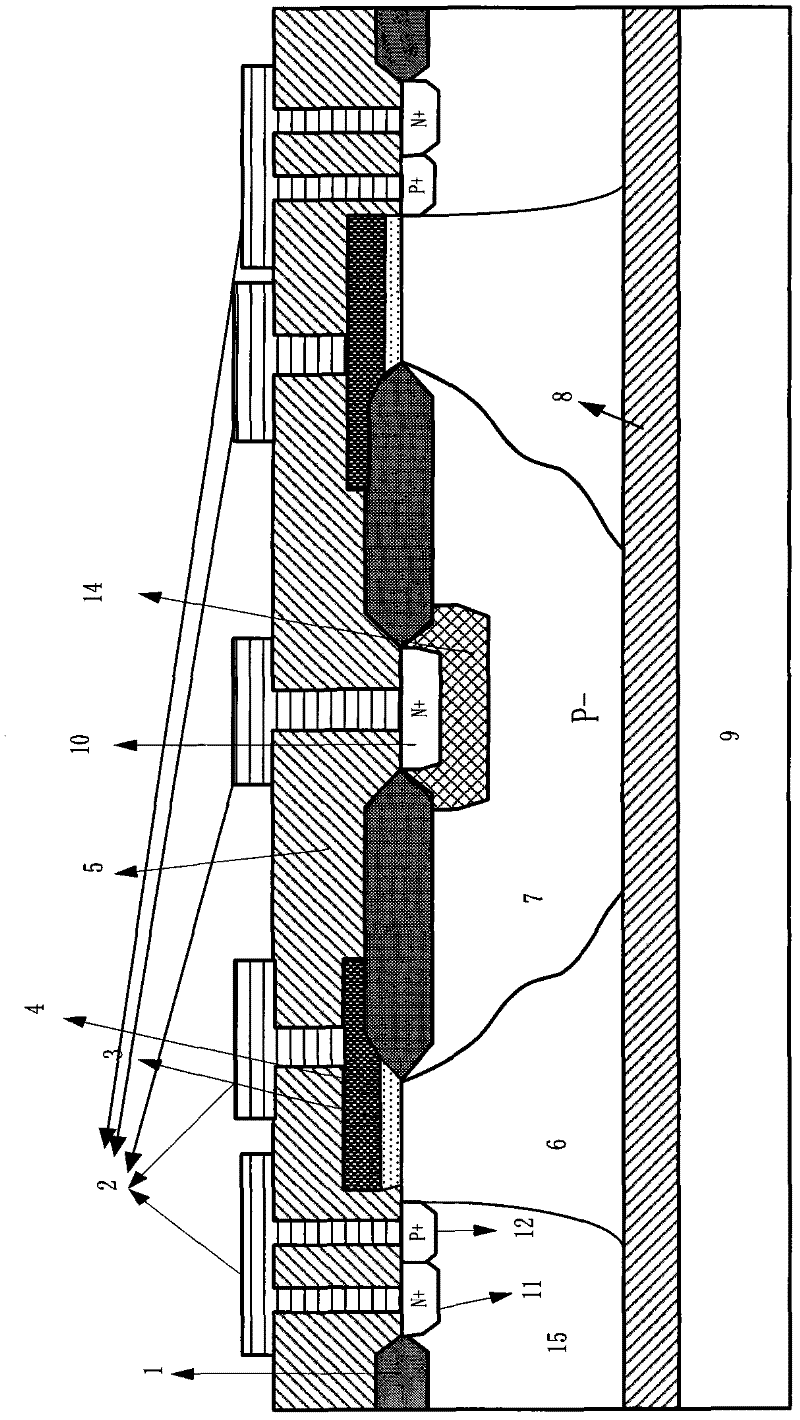

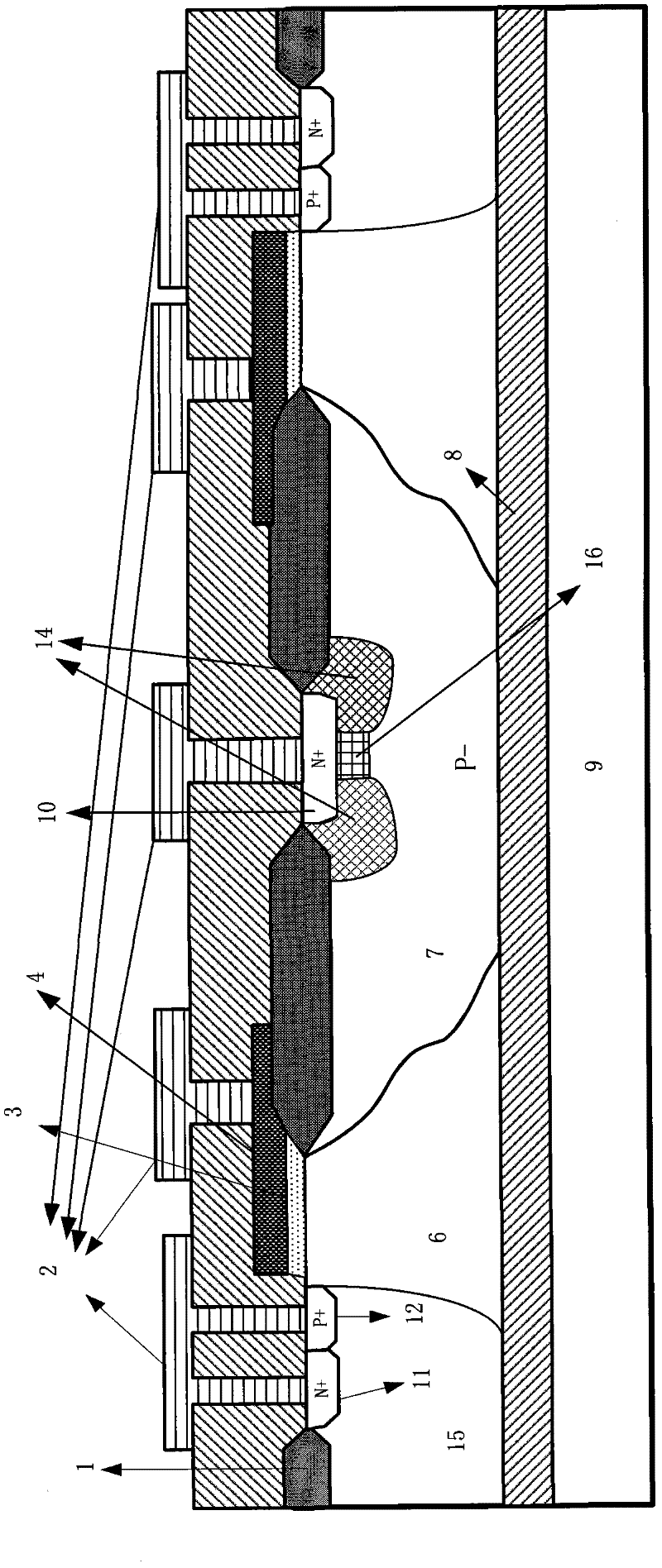

[0035] refer to figure 2 , a P-type silicon-on-insulator lateral device for increasing current density, comprising: an N-type semiconductor substrate 9 is provided with a buried oxide layer 8 on the semiconductor substrate 9, an N epitaxial layer 6 is provided on the buried oxide layer 8, and The N epitaxial layer is provided with a P-type drift region 7 and an N-type well region 15, and a P-type source region 12 and an N-type contact region 11 are arranged on the surface of the N-well region 15, and a P-type drift region 7 is provided on the P-type drift region 7. A buffer zone 14, an N-type drain region 10 is provided above the P-type buffer zone 14, and a gate oxide layer 3 is also provided on the surface of the N epitaxial layer 6, and the gate oxide layer 3 extends from the N epitaxial layer 6 to the P-type drift region 7. In the P-type source region 12 and the N-type contact region 11 on the surface of the N-type well region 15, a field oxide layer 1 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com