Modulated electromagnetic stirring of metals at advanced stage of solidification

A technology for electromagnetic stirring, modulating magnetic fields, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., which can solve problems such as limiting usefulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

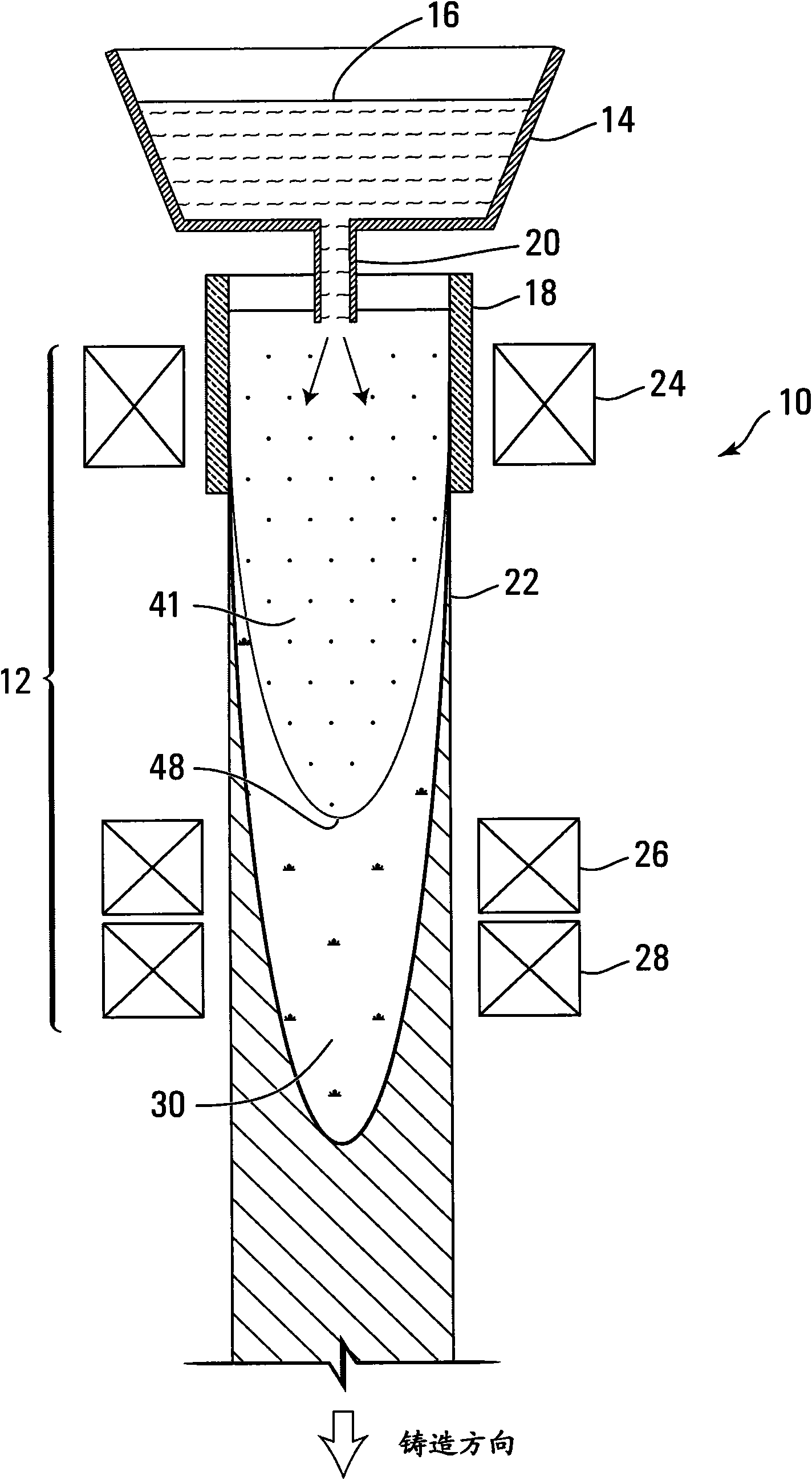

[0030] figure 1 is a schematic cross-sectional view of a continuous casting machine 10 including an EMS system 12 illustrating one embodiment of the present invention. The casting machine 10 includes a hopper 14 from which molten metal, such as liquid steel, is conveyed through a submerged inlet nozzle 20 into a mold 18 . A strand 22 with an outer shell surrounding the melt 41 is formed in the mold 18 . Strand 22 exits from the bottom of mold 18 .

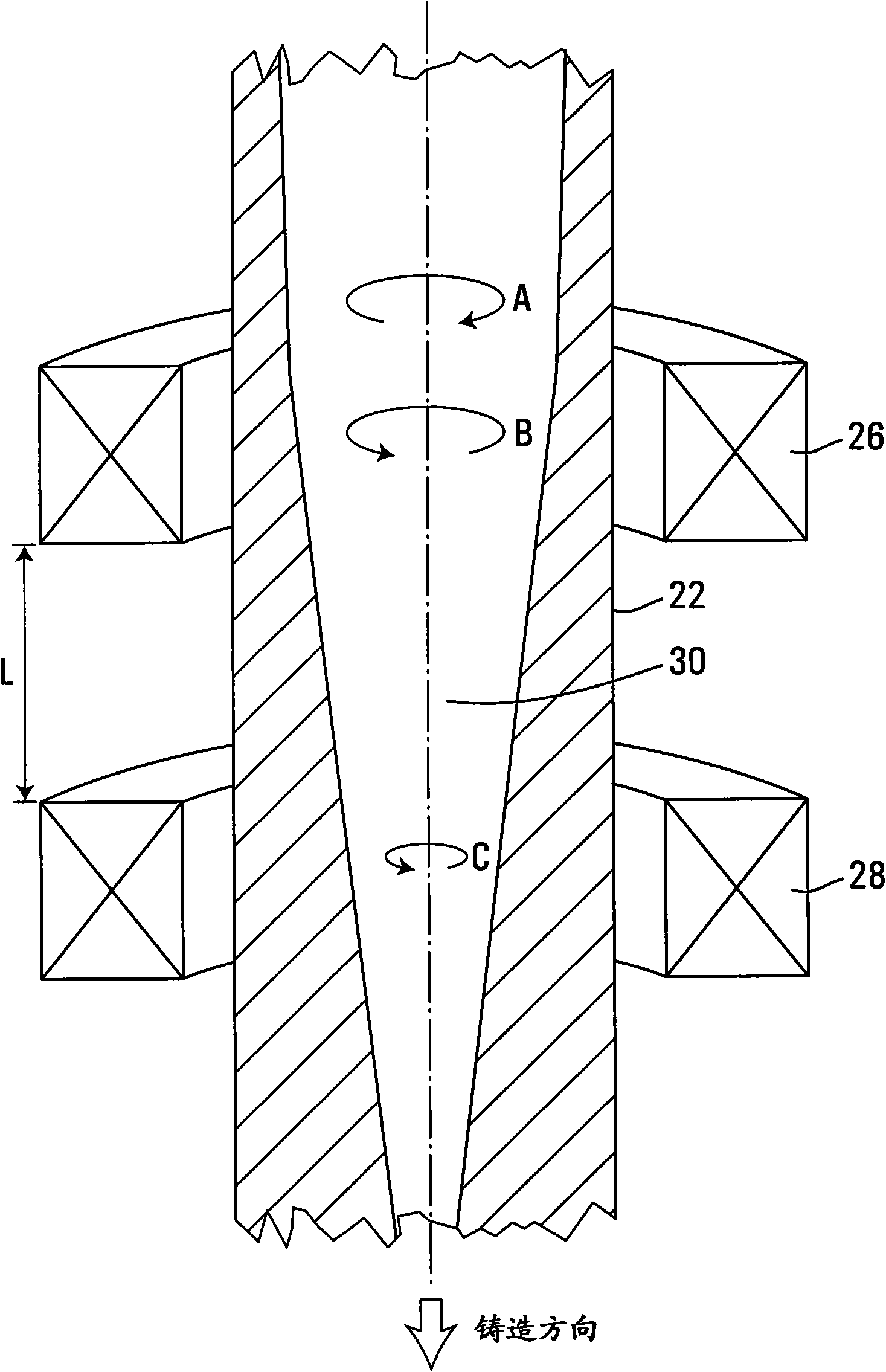

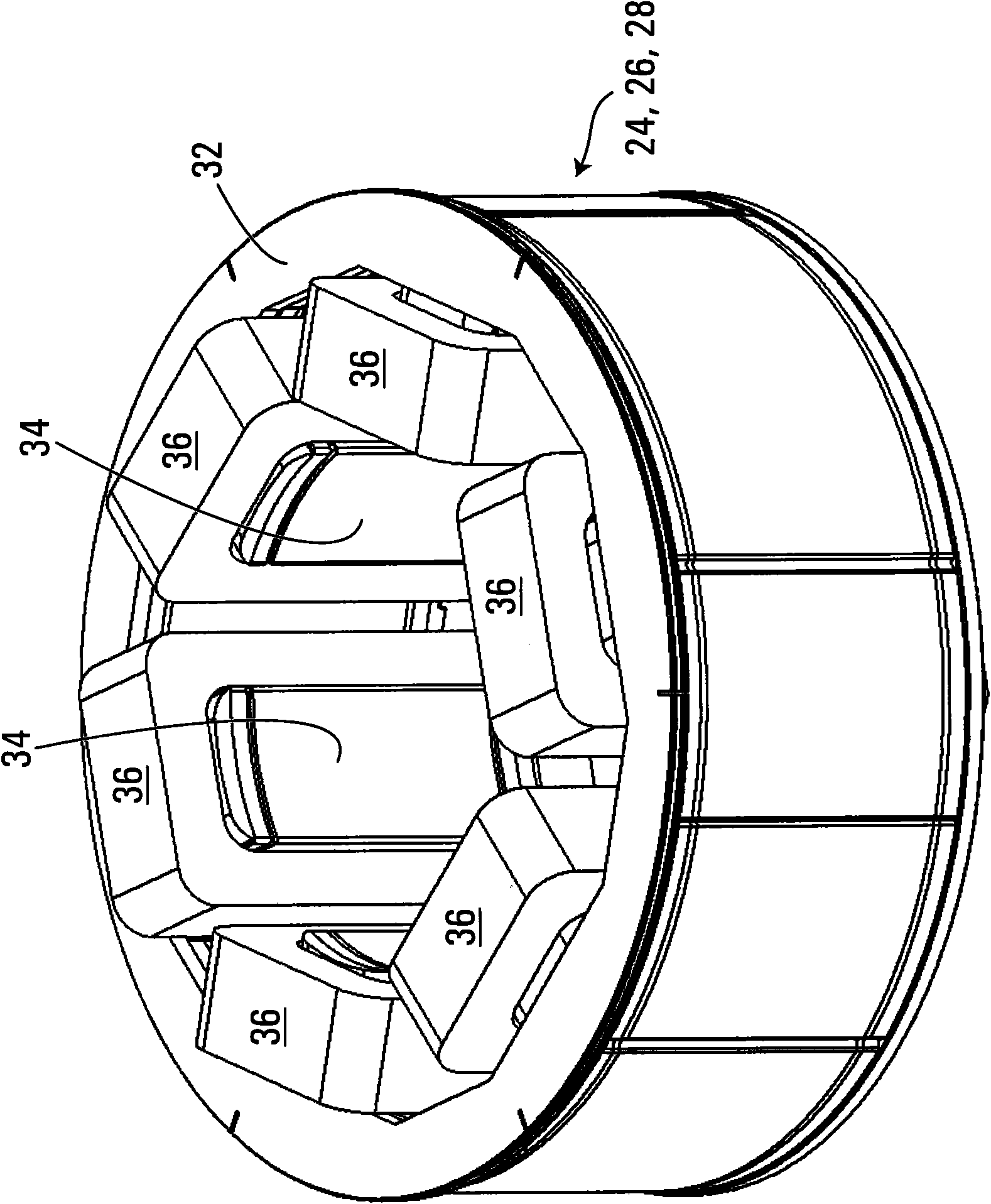

[0031] The example EMS system 12 generally includes at least one electromagnetic stirrer 24 disposed about the mold 18 . The stirrer 24 should be arranged within the mold shell or can be encased in a shell (not shown) surrounding the mold. As will become apparent, the stirrer 24 is arranged to induce a stirring motion within the melt inside the mold 18 during the early solidification stage. In the illustrated embodiment, only one stirrer 24 is arranged around the mold 18 to induce rotational stirring of the melt in the mold 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com