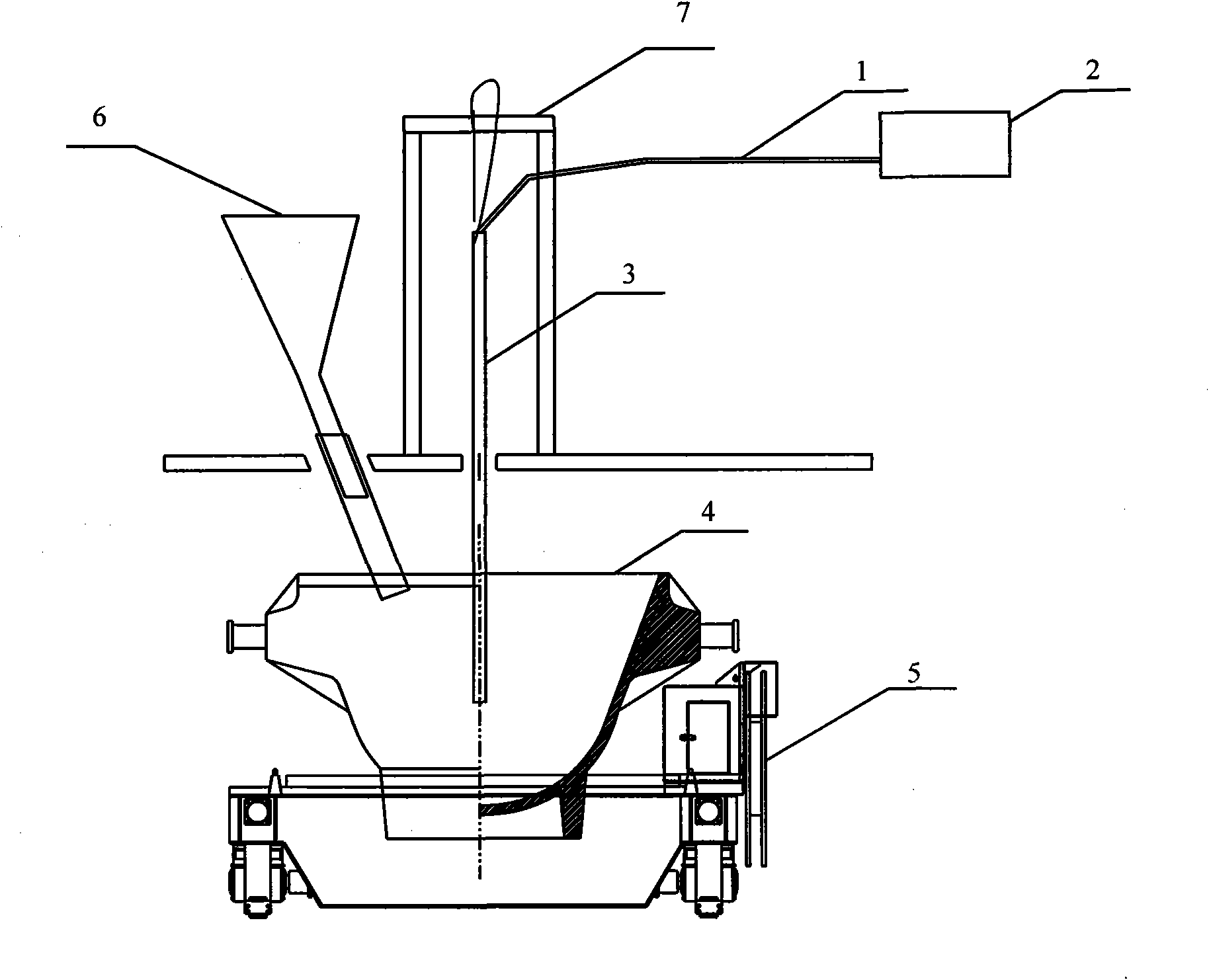

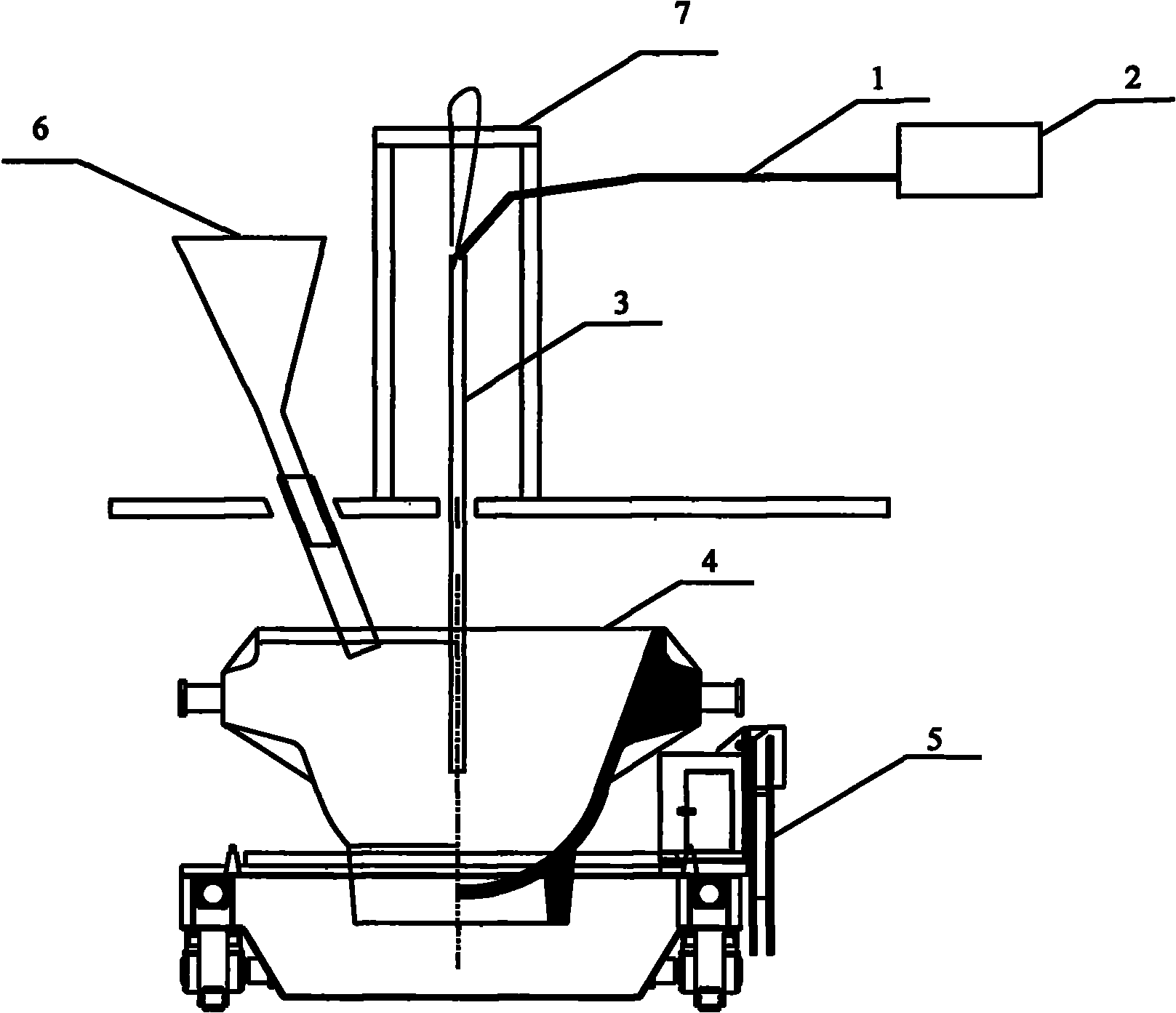

Slag liquefaction heating process and device

A heating device and steel slag technology, applied in recycling technology, manufacturing converters, etc., can solve the problems of poor fluidity of steel slag and large fluctuation of fluidity of converter steel slag, and achieve the improvement of liquid slag temperature, volume stability, and processing. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Steel slag liquefaction heating up process of the present invention, steps are as follows:

[0011] a. Before converter slag dumping, drive the slag tank car loaded with slag tank to the slag receiving position at the bottom of the furnace and stop it. The operator checks the slag condition in the tank;

[0012] b. If the flow performance of the steel slag in the tank meets the requirements of wind crushing or water quenching, immediately drive the slag tank truck to the tank lifting position, and use the driving car to hoist the slag tank to the steel slag wind crushing line or water quenching line for treatment; if the steel slag in the tank flows If it is confirmed that the temperature needs to be raised, start the steel slag liquefaction heating device, lower the oxygen blowing spray gun, and open the oxygen valve to blow oxygen when the spray gun drops to close to the slag surface (the oxygen valve is automatically opened by the limit switch control), and the spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com