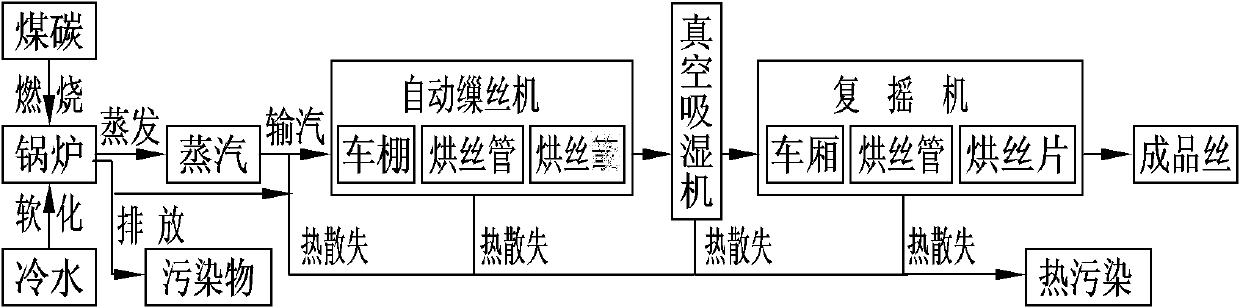

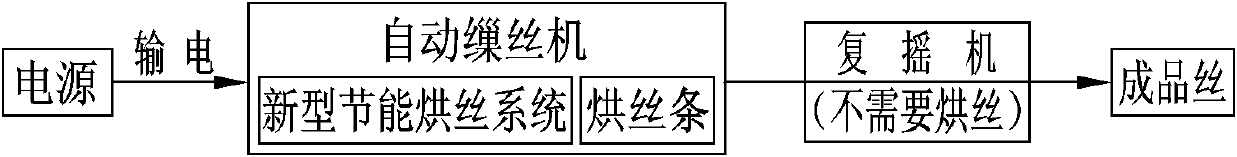

Novel energy-conservation silk drying system of automatic silk reeling machine

A silk reeling machine, a new type of technology, applied in the direction of silk reeling, artificial filament cleaning/drying, etc., to achieve the effect of improving energy utilization, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

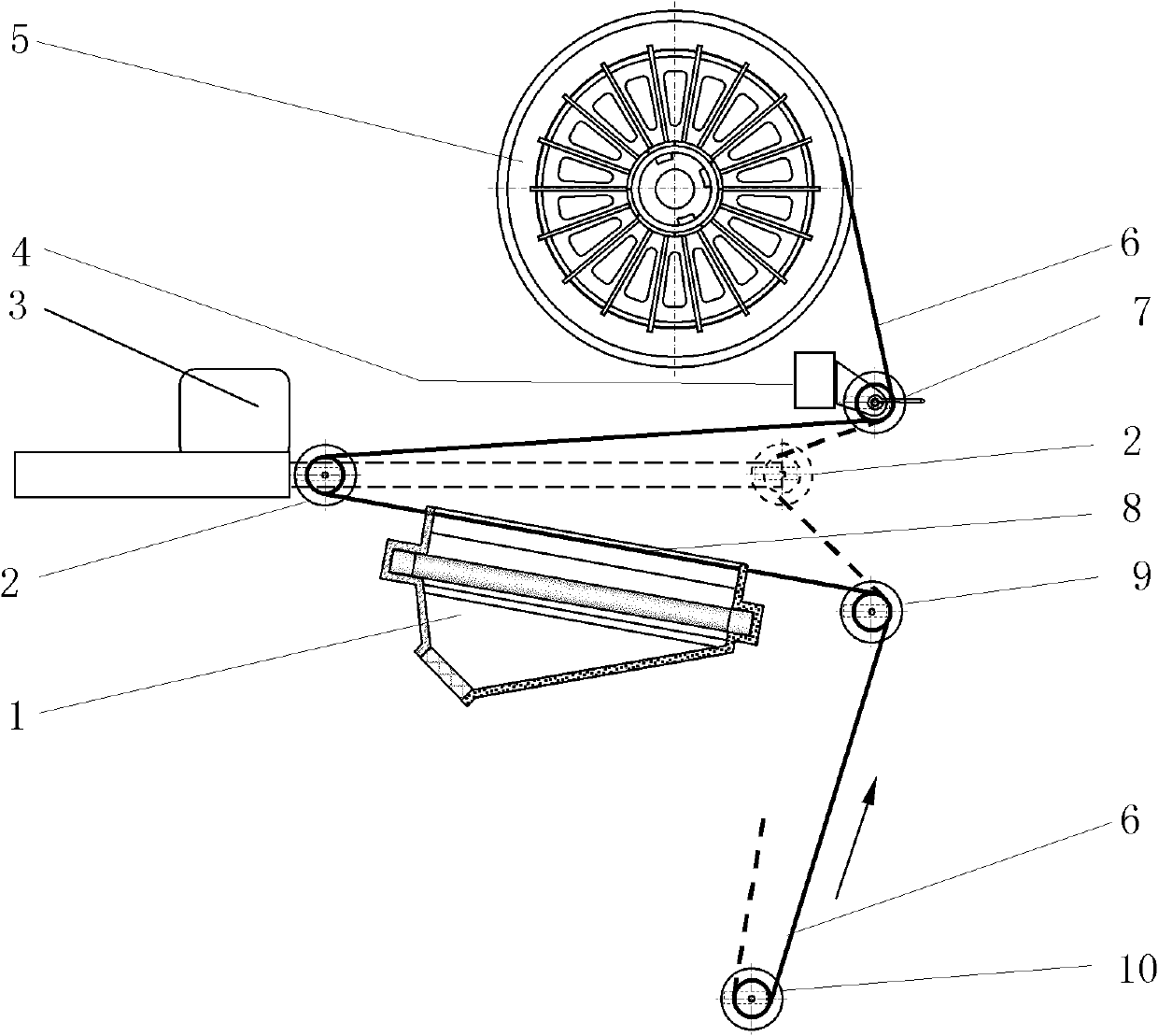

[0029] see Figure 3-Figure 6 , the present invention includes compensating drum 10, twisting rod 4, wire-discharging drum 7 and small 5. The key technology is to install the import drum 9 of the silk dryer at the silk outlet of the compensation drum 10, install the far-infrared silk dryer 1 next to the import drum 9 of the silk dryer, and install the far-infrared silk dryer 1 at the outlet of the far-infrared silk dryer 1. The photoelectric automatic wire-moving mechanism 3 is installed at the silk mouth, and the silk outlet of the photoelectric automatic wire-moving mechanism 3 is a wire-discharging drum 7. The far-infrared silk dryer 1 has a silk dryer shell 12, an air inlet is opened under the silk dryer shell 12, an axial flow fan 13 is installed at the air inlet, and in the silk dryer shell 12 along the air inlet direction A uniform flow bin 14, a reflective heating bin 15 and a diversion bin 17 are arranged in turn, and a far-infrared quartz electric heating tube 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com